Live Chat

Click the buttonBottled Orange Juice Processing Line / Processing Machine Concentrated Automatic 1T-10T/H

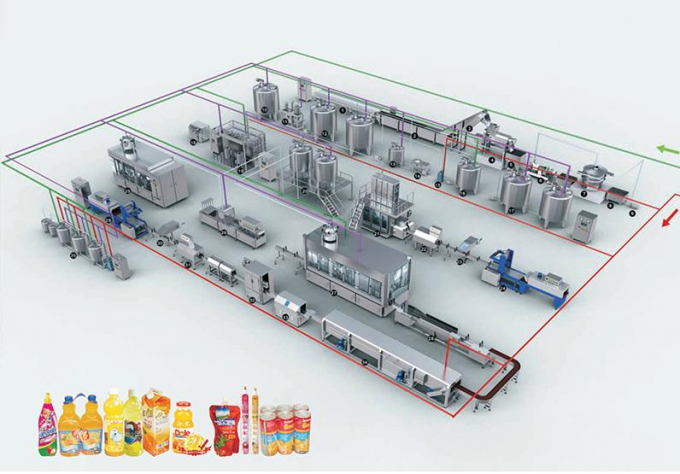

This production line in a variety of fresh fruit, juice concentrate, fruit powder as the main raw material, through dilution, extraction, cooking, crushing, homogenate, degassing, filling and a series of process, processing production made into all kinds of fruit juice, fruit juice beverage flavor.

Products

-

Bag Filling Machine

-

Beverage Filling Line

-

Biscuit Making Machine

-

Biscuit Production Line

-

Bottle Blowing Machine

-

Carbonated Drink Production Line

-

Cosmetic Filling Machine

-

Drink Production Line

-

Drinking Water Filling Machine

-

Drinking Water Production Line

-

Edible Oil Production Line

-

Fruit Juice Processing Line

-

Juice Filling Machine

-

Plastic Injection Molding Machine

-

Snack Food Production Line

-

UHT Milk Processing Line

-

Water Treatment Systems

-

Vertical Packaging Machine

-

Other Packaging Machine

-

Pillow Type Packaging Machine

-

Pre-made Pouch Packing Machinery

-

Measuring Equipment

-

Cup Filling Machines

-

Conveyor Equipment

-

Auxiliary Equipment

| Type: | Orange Juice Processing Equipment | Condition: | New |

|---|---|---|---|

| Application: | Food, Beverage, Machinery & Hardware | Packaging Type: | Case |

| Packaging Material: | Wood | Certification: | ISO,CE,SGS |

| Processing Type: | Juice Water Carbonated Drinks In PET | Bottle Type: | Round Bottle, Case Bottle ,square Bottle, Flat Bottle |

Concentrated Automatic 500KG -10T/H Bottled Orange Juice Processing Line / Processing Machine

Product Description

This production line in a variety of fresh fruit, juice concentrate, fruit powder as the main raw material, through dilution, extraction, cooking, crushing, homogenate, degassing, filling and a series of process, processing production made into all kinds of fruit juice, fruit juice beverage flavor.

Product Features

- High standards of design, manufacturing and project installation requirements, guaranteed a variety of beverage production line first-class finished products.

- The production line is equipped with programmable Siemens PLC controller, and the whole production line is fully automatic, saving manpower and facilitating production management.

- Fully automatic CIP cleaning to ensure the whole production line equipment meets the food hygiene safety requirements.

- The last trace of moisture is the most difficult to remove unless it is used with high export drying temperatures to provide sufficient driving force. Due to the adverse effect of rising drying temperature on the quality of powder, it is necessary to operate with dairy products at lower outlet temperatures. If the moisture content of the powder is still too high, then after drying and drying, it will be added to the post-drying stage in the two-stage process.

- The two-stage drying method of milk powder: the combination spray drying is the first stage and the fluidized bed is the second stage. The moisture content of the powder leaving the drying chamber is 2 ~ 3% higher than the final moisture content. Fluidized bed dryer is used to remove excess water and finally cool the powder.

- According to the quality and requirements of consumers, powder is packaged in cans, paper bags, laminated bags or plastic bags.

- Milk powder production needs to be into powder, liquid milk drying of herbs, spices and pigments and many important components such as protein, fat, carbohydrate, vitamins, minerals, etc. Be preserved. The additional challenge is a uniform moisture content, particle structure, particle size distribution, solubility, dispersibility, and wettability.

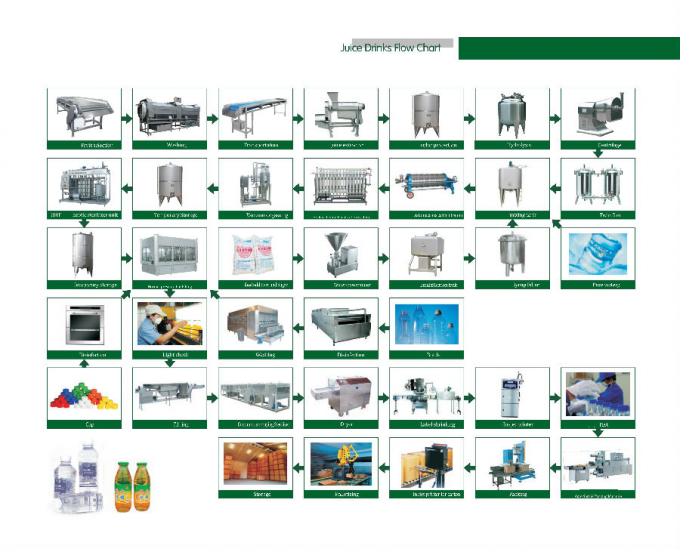

Flow Chart:

We are able to supply whole production line for juice ,Send us now We will make a business proposal for you with professional design.

Specification:

| production | Various fruit juice,concentrate,juice powder |

| Capacity | 2T/D–50T/D |

| Endproduct package | bottle,Tin, plastic bag |

| Run | Stable |

| voltage | 220V/380V |

| certification | CE ISO |

| Project | Turn-key Project |

Product Show:

|

|

|

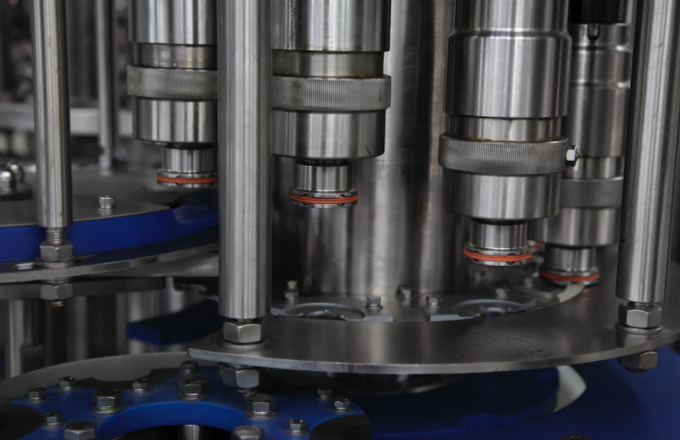

Filling Parts: |

|

|

Capping Parts: Raw material: Food Grade Stainless Steel SUS304 Capping type: Rotary screw capping Adopts Italy advanced technology, more stable and durable. |

|

PLC and Touch Screen Brand: Siemens Original: Japan Using international brand electrical components to ensure machines running in good condition for longer time. |

|

|

|

|

Output Product

-

1000 BPH- 25000 BPH 3 In 1 Filling Machine , Automatic Fruit Juice Processing Machines

1000 BPH- 25000 BPH 3 In 1 Filling Machine , Automatic Fruit Juice Processing Machines

Juice filling production line is mainly used for washing bot...

→ -

Stainless Steel Fruit Juice Processing Line 2T-5T/H Apple Juice Production Line

Stainless Steel Fruit Juice Processing Line 2T-5T/H Apple Juice Production Line

the orange juice processing line includes whole steps: veg...

→ -

Small Scale Fruit Juice Processing Line / Tea Manufacturing Equipment SUS304

Small Scale Fruit Juice Processing Line / Tea Manufacturing Equipment SUS304

The juice production line is mainly used for beverage juice ...

→ -

Commercial Fruit Juice Production Equipment ,12000 BPH Fruit Juice Manufacturing Plant

Commercial Fruit Juice Production Equipment ,12000 BPH Fruit Juice Manufacturing Plant

The machine is used for juicing, tea and other non-air drink...

→