Products

-

Bag Filling Machine

-

Beverage Filling Line

-

Biscuit Making Machine

-

Biscuit Production Line

-

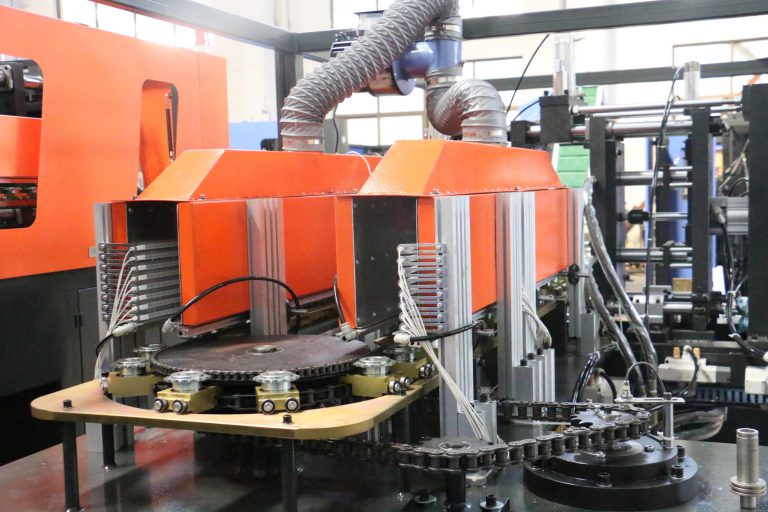

Bottle Blowing Machine

-

Carbonated Drink Production Line

-

Cosmetic Filling Machine

-

Drink Production Line

-

Drinking Water Filling Machine

-

Drinking Water Production Line

-

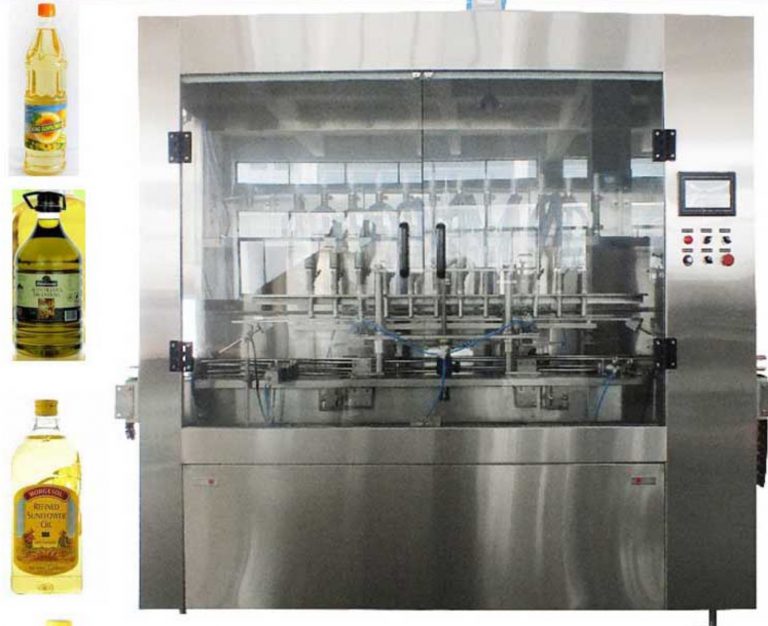

Edible Oil Production Line

-

Fruit Juice Processing Line

-

Juice Filling Machine

-

Plastic Injection Molding Machine

-

Snack Food Production Line

-

UHT Milk Processing Line

-

Water Treatment Systems

-

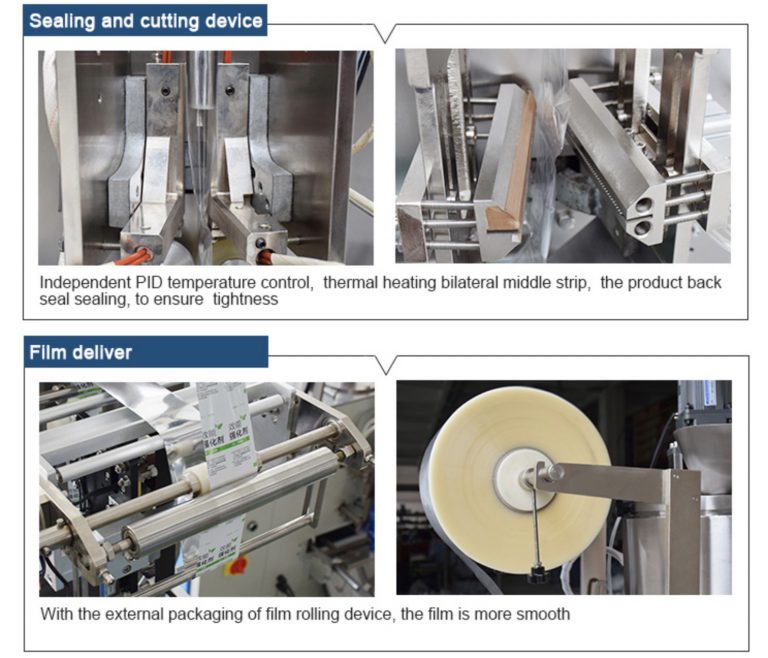

Vertical Packaging Machine

-

Other Packaging Machine

-

Pillow Type Packaging Machine

-

Pre-made Pouch Packing Machinery

-

Measuring Equipment

-

Cup Filling Machines

-

Conveyor Equipment

-

Auxiliary Equipment

No drop leak,bottom diving fill,no foam plc control bottle juice filling machine

Bottle filliing, nozzle, no drip | PLCS.net - Interactive Q & A

Their old machine has overflow nozzles that seems to always drip and leaks and for some reason the removed the drip tray. Is drip unavoidable and is just something that has to managed or is some way to eliminate that?

Bottle Filling PLC Ladder Logic - Automation Community

In this problem, write a PLC ladder logic for filling a bottle for 7 seconds based on a fixed time interval using timers.

Basic Troubleshooting for the Overflow Filling Machine

If the fill times are not adjusted, there may not be enough overflow time to result in a level fill. Finally, operators should do a visual inspection of the nozzles and tubes to ensure there are no leaks or blockages that may be affected the flow of the liquid. HEAD DIVE NOT WORKING

Controlling Excessive Foaming During a Product Fill

The first solution for excessive foam is the overflow filling machine. The principle behind this liquid filler allows packagers to control foam. The overflow filler is a unique piece of equipment in that it fills bottles to a specific level, rather than by volume.

Bottle Filling and Capping Project using PLC Ladder Logic

We have learned all basics of ladder logic including contacts and coils operation, logic gates, rising and falling edges, timers, and counters. So, today we will utilize all of these components to implement a complete ladder program of filling and capping problems.

Troubleshooting Leaks on Overflow Filling Machines

On many occasions, a leak on an overflow filler at the bottle opening can be fixed by simply adjusting the starting height of the fill bar. If the fill heads start too high, the nozzles will not dive far enough to create the necessary seal over the bottle openings.

Liquid Bottle Filling Machine | Two Head Automatic Piston Filler

No Bottle/No Fill Sensor prevents filling when no bottles are present. Adjustable Back-up Sensor pauses the line when needed. Portable System Cart for Piston Filler, Control Enclosure, and Diving Head Assembly. Specifications. Electric: 120VoltAC/1 phase/50-60Hz/20 Amps. Compressed Air: Up to 5 CFM at 90 PSI, must be clean and dry.

Bottle & Liquid Filling Machines | Custom Filler Line Systems

E-PAK Machinery is the leading provider of inline filling machines and liquid packaging machinery, offering a wide variety of fillers with manual, semi-automatic and fully automatic functions.

Automatic Oral Liquid Filling Machine Vial Filling Stoppering ...

Bottom diving fill, no foam. Suitable to various sizes of container, easy adjusting, short time cost. Change the parts on the stoppering machine can easily achieve half stoppering fuction.

Automatic Bottle Filling & Capping Machine Using PLC

Capping machines are used to cap the bottles filled with material. So here we develop a system to demonstrate the filling as well as capping system used for bottles in industries using PLC and mechanical assembly.