Products

-

Bag Filling Machine

-

Beverage Filling Line

-

Biscuit Making Machine

-

Biscuit Production Line

-

Bottle Blowing Machine

-

Carbonated Drink Production Line

-

Cosmetic Filling Machine

-

Drink Production Line

-

Drinking Water Filling Machine

-

Drinking Water Production Line

-

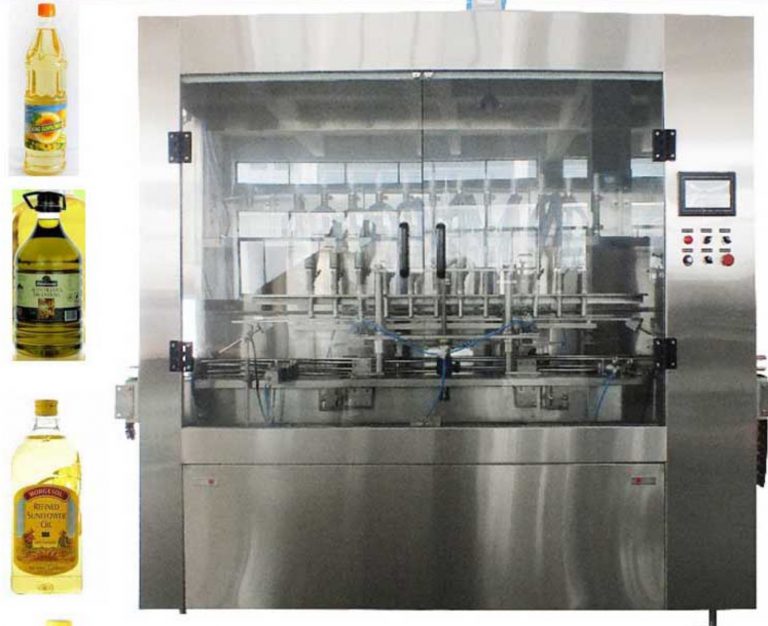

Edible Oil Production Line

-

Fruit Juice Processing Line

-

Juice Filling Machine

-

Plastic Injection Molding Machine

-

Snack Food Production Line

-

UHT Milk Processing Line

-

Water Treatment Systems

-

Vertical Packaging Machine

-

Other Packaging Machine

-

Pillow Type Packaging Machine

-

Pre-made Pouch Packing Machinery

-

Measuring Equipment

-

Cup Filling Machines

-

Conveyor Equipment

-

Auxiliary Equipment

One worker needed under cap aerosol filling machine /aerosol can filling machine

Fill-One+ Aerosol Filling Machine (EBAA1014) | Fillon ...

Fill-One introduces a patented filling cylinder and integrated piston disc in place of traditional aerosol cap- so there’s nothing to clean. Simply remove the cylinder cap, piston disc, and spray nozzle, and fill the cap with paint according to the formula.

Manual Fill-One+ Machine (EBAC1004) | Fillon Technologies

No Cleaning after filling aerosol cans. Seconds to fill with no loss of paint product. Compact system- about the size of a coffee maker. Paint is permanently sealed into the cap, serving as a color indicator. No compressor required- a simple, hand crank operation. Safe and surefire- no guessing about the number of strokes.

Fill-One+ (Pneumatic) Aerosol Filling Machine Tutorial - YouTube

Fill-One+ (Pneumatic) Aerosol Filling Machine Tutorial. Fillon Technologies Workshop. 78 subscribers. 13. 2.4K views 3 years ago. Fill-One Instructional Tutorial ...more.

AEROSOL PRODUCTION & FILLING TECHNOLOGY - SATA

Pros: Only 1/4 to 1cc gas loss between the aerosol valve and gassing head each cycle. On-Line gas blending past and present (Gassing the can more than once with 2-3 gasses) Maintenance is minimal (O-ring or a seal) Modern Valves Fill at 100cc per second.

Fill-One Custom Can Filling Machine Pneumatic - U-Pol

Time and cost savings with clean, easy to use, convenient U-POL CUSTOM CAN FILL-ONE Aerosol Filling System. Fills quickly in 10 seconds; Easy to use – no need to measure or mix; Proprietary cap leaves a color swatch for easy identification; Minimizes labor and cleaning time; No loss of paint product or waste; Pneumatic operation from a ...

Fill-One Aerosols - U-Pol

Delivers a finish similar to a spray gun. Pre-gassed ready to be filled with any color of paint. Supplied with a Fill-One cap to use with the Custom Fill-One machine. Available in water-based and solvent-based compatible aerosols.

Under-cap Propellant aerosol can filling machine

AEROSOL FILLING TECHNOLOGY. The only gas filling machine that is a gassing room itself. Single and double indexing movement equipped with all the safety requirements of a standard gas house. Left, double indexing 1¡± aerosol valves filling line. Speed up to 90 cpm. Coster: Your Global Partner

Custom Can Fill-One Filling Machine - U-Pol

Fill-One Custom Can pneumatic and manual aerosol filling machine. Ideal for filling single aerosols, one colour at a time. Fast filling – fill aerosols in 10 seconds. Unique colour indicator cap to prevent repeat fills. Compatible with pre-gassed Custom Can Fill-One aerosols.

Seymour Z-2501 Fill One Machine | Spray Paint, Empty Aerosol ...

An aerosol can filling machine that uses compressed air to fill pre-charged cans. Our unique cap lets you avoid messy prep and cleanup while leaving you with the actual color inside the cap for easy reference.

CZM300 - Aerosol Filling Machine One Shot

Features. Compact in design, this pneumatic aerosol filling machine fills aerosol cans in seconds. • Accurate and safe filling of pre–gassed cans with minimal clean up required. • Simple single shot push button operation. • Suitable for use with water-based and solvent-based compatible aerosols.