Products

-

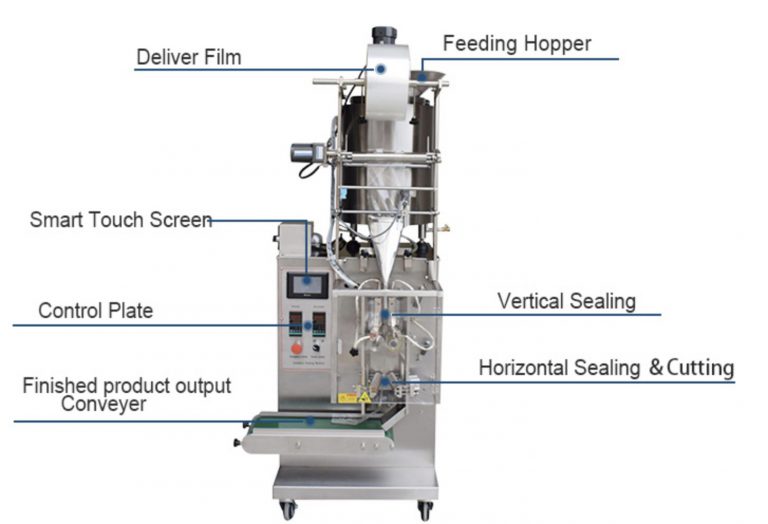

Bag Filling Machine

-

Beverage Filling Line

-

Biscuit Making Machine

-

Biscuit Production Line

-

Bottle Blowing Machine

-

Carbonated Drink Production Line

-

Cosmetic Filling Machine

-

Drink Production Line

-

Drinking Water Filling Machine

-

Drinking Water Production Line

-

Edible Oil Production Line

-

Fruit Juice Processing Line

-

Juice Filling Machine

-

Plastic Injection Molding Machine

-

Snack Food Production Line

-

UHT Milk Processing Line

-

Water Treatment Systems

-

Vertical Packaging Machine

-

Other Packaging Machine

-

Pillow Type Packaging Machine

-

Pre-made Pouch Packing Machinery

-

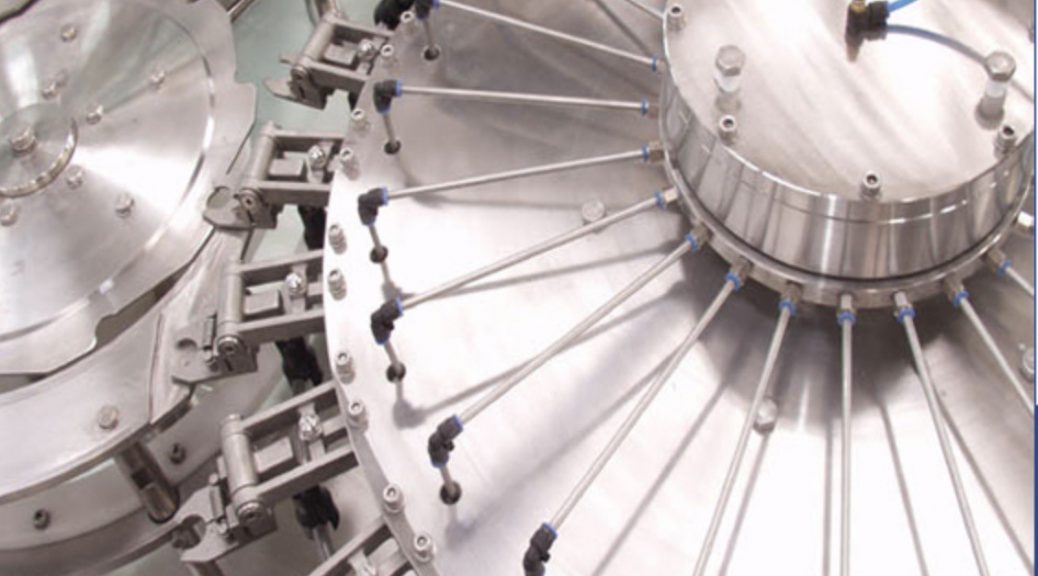

Measuring Equipment

-

Cup Filling Machines

-

Conveyor Equipment

-

Auxiliary Equipment

Automatic RO Water Treatment Plant , Stainless Steel Water Treatment Equipment

Litchi / Pulp Juice Filling Machine High Capacity Semi- Automatic CE Certificate

High Capacity Carbonated Drink Production Line Machine For 500ml-2500ml Bottle

3 In 1 Plastic Bottle Beverage Filling Machine , Automatic Soft Drink Filling Machine

Red Bull Energy Drink Production Line Automatic For Glass / PET Bottle

Fully Automatic Drinking Water Filling Machine 600-3000BPH For 5 Gallon PET Bottle

Bottled Mineral Drinking Water Production Machine / Filling Production Line

SUS304 PET Bottle Edible Oil Bottle Filling Machine For Non Viscous Liquid Filling

sanitizing agent Filling Machine

Sanitizing Agents | MoreWine

Sanitizing Agents. MoreWine! offers the following sanitizing agents to cover all of your winemaking sanitization needs: Star San and SaniClean: Star San and SaniClean are two next generation sanitizers that are based on acid anionics. When used at their recommended concentrations, they are quick, odorless, tasteless and safe for most

SANITATION STANDARD OPERATING PROCEDURE – Processing

Residual sanitizer is flushed out of the lines by pumping approximately three gallons of ice cream mix through the circuit and draining it onto the floor. On days when the dixie cup or pint filling equipment is used it is likewise sanitized prior to use with a chlorine sanitizer which is allowed to drain to the floor. 4.

Effective Cleaning and Sanitizing Procedures - JIFSAN

Effective Cleaning and Sanitizing Procedures scrapers, foaming equipment, water guns, etc., should be cleaned and sanitized. (surface active agent) is a

Sanitizers and Disinfectants: The Chemicals of Prevention

Sanitizers and Disinfectants: The Chemicals of Prevention. with added chelating agents that allow such use.[11] of equipment cleaning and sanitizing in food

Food Safety Education | For Educators | Competencies | For

Define cleaning and sanitizing and the differences between the two procedures. I. CLEANING Cleaning is the process of removing food and other types of soil from a surface, such as a dish, glass, or cutting board.

CLEANING & SANITIZING EQUIPMENT - accupacking

CLEANING & SANITIZING EQUIPMENT Cleaning & Sanitizing Equipment, Page 2 THREE COMPARTMENT SINK SHALL BE PROVIDED AND USED AS FOLLOWS: 1. Large enough to immerse most equipment and utensils. 2. Supplied with Cold Water and Hot Water at least 110°F that reaches all three compartments. 3.

Hand Sanitizer Filling Machine - YouTube

Hand sanitizer filling machine , hand sanitizer liquid filling machine, Automatic Hand Sanitizer Liquid Soap Filler Machine, Piston Bottle Filling Machine, liquid hand sanitizer honey filling

CLEANING AND SANITIZING - Food safety

Chemical-Sanitizing Machines • Chemical sanitizing machines often wash at much lower temperatures, but not lower than 120oF (49oC). • Rinse water temperature in these machines should be between 75oF and 120oF (24oC and 49oC) for the sanitizer to be effective. Cleaning and Sanitizing in a Three-Compartment Sink 1.

FS14/FS077: Basic Elements of Equipment Cleaning and

This document explains the details of equipment cleaning and sanitizing procedures in food-processing and/or food-handling operations. Background Cleaning and Sanitizing Program . Since cleaning and sanitizing may be the most important aspects of a sanitation program, sufficient time should be given to outline proper procedures and parameters.

Sanitizer Machine, Sanitizer Machine Suppliers and

accupacking offers 5,856 sanitizer machine products. About 5% of these are filling machines, 5% are paper product making machinery, and 5% are mixing equipment. A wide variety of sanitizer machine options are available to you, such as liquid, viscous fluid.

sanitation of filling machines for food and beverage - Winpak

will focus primarily on sanitation of filling machinery associated with . TYPES OF CHEMICAL CLEANING AGENTS Sanitizer for CIP Washing Of CIP Capable.

Sanitizing Agents | MoreWine

Products 1 - 15 of 15 Make sure your wine making equipment is sanitized with the best MoreWine! offers the following sanitizing agents to cover all of your

Cleaning and Sanitizing of Containers and Equipment | DRINC

small vats, cultured product packaging equipment appurtenances, tanker .. Chlorine is the most common chemical sanitizing agent used in the milk industry.

Basic Elements of Equipment Cleaning and Sanitizing in Food

sanitized equipment and surfaces drain dry and are . oxidizing agents (such as chlorinated detergents) for removal. . formulations as a filler. Sodium chloride

cleaning and sanitizing - Food Safety

Cleaning is done with a cleaning agent that removes food, soil, or a high- temperature warewashing machine is used to sanitize cleaned dishes, the final sanitizing rinse Make sure all detergent and sanitizer dispensers are properly filled.

Cleaning and Sanitizing Procedures for Food Equipment | Yamato

Cleaning and Sanitizing Procedures for Food Equipment. accupacking by Yamato There are a few options you have when it comes to cleaning agents.

cleaning and sanitization - Personal Care Products Council

Commonly Used Chemical Sanitizers for Processing and Filling Equipment . . 27. 30 . antimicrobial agents including disinfectants and sanitizers. 117.

Automatic CIP units for washing and sanitizing any filling plant - Blog

Nov 22, 2013 How to clean and sterilize completely any kind of filling machines and reduce dramatically the risk of contamination.

![cleaning filler [archive] - probrewer discussion board](/wp-content/load/ps17422141-carbonated_soft_drink_filling_machine_aluminum_tin_can_gas_beverage_production_line.jpg)

Cleaning filler [Archive] - ProBrewer Discussion Board

How to circulate a cleaning agent through the filler? With an older machine you really need to use bottles or make up something to act Remember your hot sanitize wont reach the snifts or the vent tubes very well unless

Effective Cleaning and Sanitizing Procedures - jifsan

buckets, sponges, scrapers, foaming equipment, water guns we will see later, cleaning and sanitizing need to be performed in A surfactant (surface active agent) is a substance that lowers barrels on grading or packing tables. • Use the