Live Chat

Click the buttonAutomatic Soft Drink Filling Machine , 8000 – 12000 BPH Glass Bottle Soda Filling Machine

Automatic soda water carbonated beverage machine/beverage production line is used in PET bottle filling carbonated beverage (including beverage), such as coke, Pepsi cola, alcoholic beverage, etc. 1. The filling machine can be used for washing and filling and sealing on one machine. It can also be installed on the RO water treatment, labeling machine and shrink wrapping machine. 2. The volume of water filled PET bottle filling and sealing device is 0.25l-2l and the speed is 2000-36000pcs/hour, and it can be adjusted.

Products

-

Bag Filling Machine

-

Beverage Filling Line

-

Biscuit Making Machine

-

Biscuit Production Line

-

Bottle Blowing Machine

-

Carbonated Drink Production Line

-

Cosmetic Filling Machine

-

Drink Production Line

-

Drinking Water Filling Machine

-

Drinking Water Production Line

-

Edible Oil Production Line

-

Fruit Juice Processing Line

-

Juice Filling Machine

-

Plastic Injection Molding Machine

-

Snack Food Production Line

-

UHT Milk Processing Line

-

Water Treatment Systems

-

Vertical Packaging Machine

-

Other Packaging Machine

-

Pillow Type Packaging Machine

-

Pre-made Pouch Packing Machinery

-

Measuring Equipment

-

Cup Filling Machines

-

Conveyor Equipment

-

Auxiliary Equipment

| Type: | Automatic Soft Drink Filling Machine | Condition: | New |

|---|---|---|---|

| Application: | Apparel, Beverage, Chemical, Commodity, Food, Machinery & Hardware, Medical, Textiles | Automatic Grade: | Automatic |

| Warranty: | 1 Year Free | Processing Types: | Washing Filling Capping |

| Product Advantage: | Space Saving/Effective Cost/Easy Operation | Filling Accuracy: | ≥99% |

Automatic Soft Drink Filling Machine , 8000 – 12000 BPH Glass Bottle Soda Filling Machine

Product Description

Automatic soda water carbonated beverage machine/beverage production line is used in PET bottle filling carbonated beverage (including beverage), such as coke, Pepsi cola, alcoholic beverage, etc. 1. The filling machine can be used for washing and filling and sealing on one machine. It can also be installed on the RO water treatment, labeling machine and shrink wrapping machine. 2. The volume of water filled PET bottle filling and sealing device is 0.25l-2l and the speed is 2000-36000pcs/hour, and it can be adjusted.

Proudct Features

- The machine design is reasonable, the appearance is beautiful and easy to operate, the filling quantity adjustment is convenient.

- Fully comply with CE, ISO9001 and GMP standards, high filling accuracy.

- With high safety factor, the filling machine can automatically stop at low pressure, no filling, no inner plug, it can work with other machines alone.

- The perfect stainless steel bottle cleaning agent avoids the secondary pollution of contact with the bottle screw parts.

- The filling machine can be used for washing and filling and sealing on one machine. It can also be installed on the RO water treatment, labeling machine and shrink wrapping machine.

- The technology of direct contact with air conveyors ,it is more convenient to change the shape of the bottle.

- The filling machine adopts advanced bottleneck clamping and bottle lifting technology to facilitate the replacement of various sizes of bottles.

- The machine adopts the advanced bottleneck clamping system to meet the requirement of bottle height. Therefore, when using different bottles on the same machine, some parts need to be replaced, such as the guide plate and the rotary wheel.

Product Show

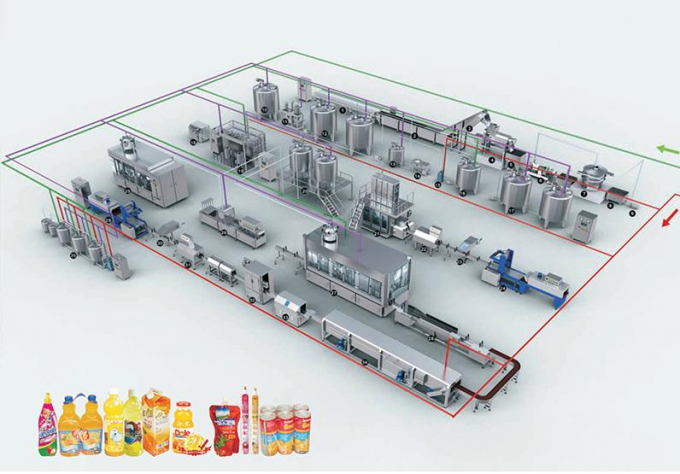

Main equipments:

juice extractor, water treatment plant, CIP cleaning system, sterilization machine, mixing tank, filling equipment.

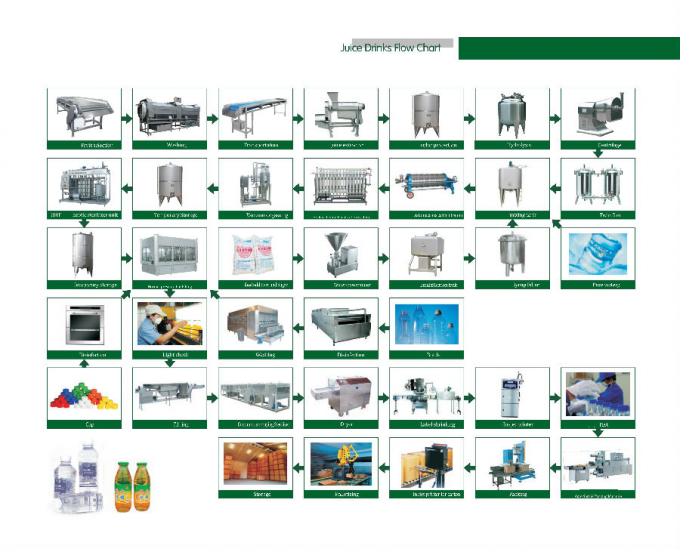

Flow Chart:

We are able to supply whole production line for juice making ,Send us now We will make a business proposal for you with professional advice of business.

Product Show:

|

Rinsing Parts:

|

|

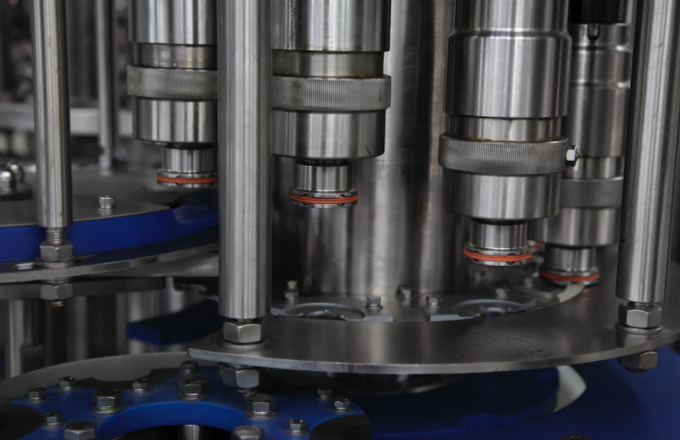

Filling Parts:

|

|

|

Capping Parts: Raw material: Food Grade Stainless Steel SUS304 Capping type: Rotary screw capping Adopts Italy advanced technology, more stable and durable. |

|

PLC and Touch Screen Brand: Siemens Original: Japan Using international brand electrical components to ensure machines running in good condition for longer time. |

|

|

high position tank made of high quality SUS304. |

high quality reflow tank for beverage juice |

Secifications:

| Model: | MT12-12-5 | MT16-12-6 | MT18-18-6 | MT24-24-8 |

| Capacity:500ml | 2000-3000bph | 3000-4000bph | 4000-5000bph | 5000-8000 |

| Bottle shape: | round or square | |||

| PET bottle: (mm) | (Bottle Diameter): φ50-φ110mm (Height): 150-310mm (Volume: 250ml -2000ml) | |||

| Cap: | Plastic screw cap | |||

| Filling precision: | ≤±5mm | |||

| Power(KW) | 3.0 | 4.0 | 4.2 | 5.2 |

| Filling pressure: (MPa) | 0.2-0.35 | 0.2-0.35 | 0.2-0.35 | 0.2-0.35 |

| Rinsing pressure: (MPa) | 0.2-0.25 | 0.2-0.25 | 0.2-0.25 | 0.2-0.25 |

| Overall size:(mm) | 1900*1500*2350 | 2250*1650*2350 | 2600*1965*2350 | 2980*2200*2250 |

| Weight: (KG) | 3000 | 3500 | 4000 | 4500 |

| Model: | MT32-32-10 | MT40-40-15 | MT50-50-15 | MT60-60-15 |

| Capacity:500ml | 8000-10000 | 10000-15000 | 16000-20000bph | 20000-24000bph |

| Bottle shape: | round or square | |||

| PET bottle: (mm) | (Bottle Diameter): φ50-φ110mm (Height): 150-310mm (Volume: 250ml -2000ml) | |||

| Cap: | Plastic screw cap | |||

| Filling precision: | ≤±5mm | |||

| Power(KW) | 6.2 | 7.5 | 8.5 | 9.8 |

| Filling pressure: (MPa) | 0.2-0.35 | 0.2-0.35 | 0.2-0.35 | 0.2-0.35 |

| Rinsing pressure: (MPa) | 0.2-0.25 | 0.2-0.25 | 0.2-0.25 | 0.2-0.25 |

| Overall size:(mm) | 3880*2200*2250 | 4000*2250*2250 | 5500*3500*2250 | 6500*5500*2250 |

| Weight: (KG) | 6000 | 7000 | 8200 |

9500

|

Output Product

Our Service

.

- We provide 1 year warranty, within a year, or if you have equipment accessories is damaged, we can provide free, in addition, we have prepared plenty of equipment spare parts in inventory, customers need to repair and maintenance spare parts at any time, can quickly provide.

- The experienced engineers and technicians are responsible for equipment installation and commissioning to ensure normal production and customers.

- We provide overseas door-to-door training service to ensure that your staff can operate and maintain the procedures correctly, and master the equipment operation.

- Provide customers with pre-project planning workshop and design.Certificate

Package

Contact Us

Send us inquery now,our professional team will contact with you with business proposal for your business!

-

Stainless Steel Wine / Zobo Drink Filling Machine , Beverage Bottling Equipment

Stainless Steel Wine / Zobo Drink Filling Machine , Beverage Bottling Equipment

This machine is used in beverage and food industry. It is us...

→ -

2000 – 18000 BPH Automatic Water Filling Machine , Commercial Fruit Juice Production Line

2000 – 18000 BPH Automatic Water Filling Machine , Commercial Fruit Juice Production Line

New bottled tea beverage production line/juice filling machi...

→ -

Fizzy Drink Production Line / Bottling Machine 6000 BPH-12000 BPH CE Certificate

Fizzy Drink Production Line / Bottling Machine 6000 BPH-12000 BPH CE Certificate

The bottle part adopts the belt conveyor system, which can a...

→ -

Energy Drink Production Line Electric Driven For Beverage High Efficiency Low Energy

Energy Drink Production Line Electric Driven For Beverage High Efficiency Low Energy

This series equipment is used for energy drinks, water, and ...

→