Live Chat

Click the buttonCarbonated Beverage Filling Line 5000 -10000 Can Per/ Hour Drink Canning Machine

This machine is used for filling and sealing the cans. Its output can reach 80 – 200 cans / min. the machine includes two functions of filling and sealing. For filling, the equipment adopts the equal pressure filling method to ensure that the carbon dioxide can be prevented from volatilizing in the liquid. The temperature is about 4 degrees. The sealing part adopts the two-stage gradual seal to ensure the quality of the package.

Products

-

Bag Filling Machine

-

Beverage Filling Line

-

Biscuit Making Machine

-

Biscuit Production Line

-

Bottle Blowing Machine

-

Carbonated Drink Production Line

-

Cosmetic Filling Machine

-

Drink Production Line

-

Drinking Water Filling Machine

-

Drinking Water Production Line

-

Edible Oil Production Line

-

Fruit Juice Processing Line

-

Juice Filling Machine

-

Plastic Injection Molding Machine

-

Snack Food Production Line

-

UHT Milk Processing Line

-

Water Treatment Systems

-

Vertical Packaging Machine

-

Other Packaging Machine

-

Pillow Type Packaging Machine

-

Pre-made Pouch Packing Machinery

-

Measuring Equipment

-

Cup Filling Machines

-

Conveyor Equipment

-

Auxiliary Equipment

| Type: | Beverage Production Line | Condition: | New |

|---|---|---|---|

| Application: | Apparel, Beverage, Chemical, Commodity, Food, Medical | Packaging Type: | Bottles, Cans |

| Automatic Grade: | Automatic | Material: | Stainless Steel 304/316 |

| Only Quick Wear Part: | Seal Ring |

Product Description

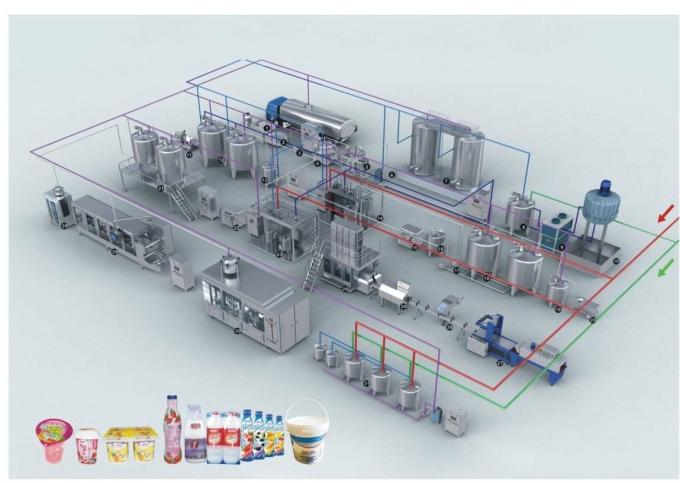

The full automatic beverage filling production line is used for the production of all kinds of beverage including juice ,beer,water and other drinks.. The whole production line can be divided into the following equipment:

Water treatment system

Juice processing system

The juice filling line.

Packing line

Our company provides the design and implementation of the production line,

Flow Chart:

We have professional team to design the whole production line for you ,contact us for more details.

Proudct Descriptions

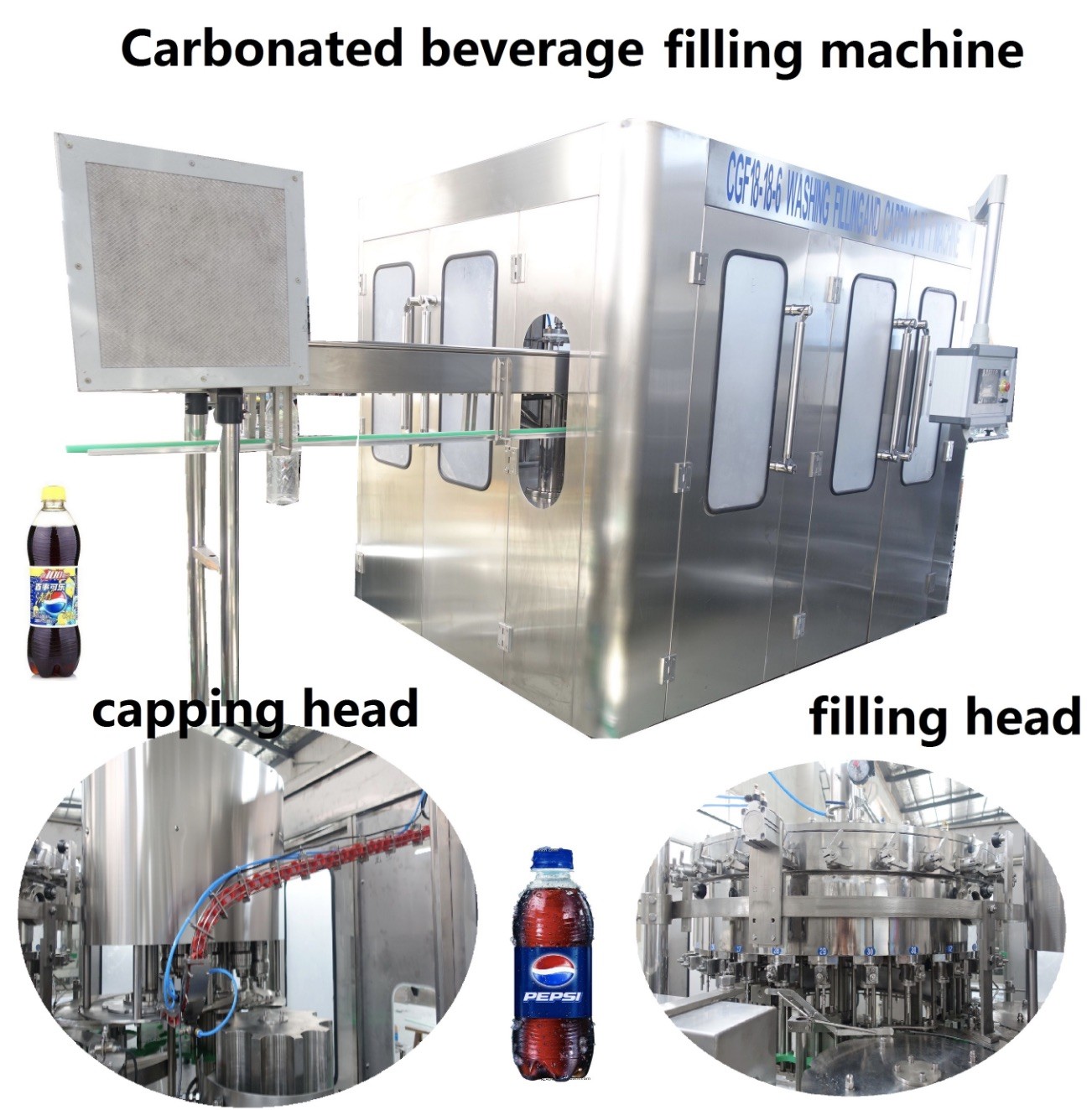

This machine is used for filling and sealing the cans. Its output can reach 80 – 200 cans / min. the machine includes two functions of filling and sealing. For filling, the equipment adopts the equal pressure filling method to ensure that the carbon dioxide can be prevented from volatilizing in the liquid. The temperature is about 4 degrees. The sealing part adopts the two-stage gradual seal to ensure the quality of the package.

Main Features:

- The device adopts the secondary exhaust function of the filling machine, which can effectively reduce the oxygen content in the tank and prolong the shelf life.

- The design of the device can adjust the production speed with the touch screen, and automatically alarm when normal failure, and give corresponding reasons. According to the severity of the fault, the intelligent system PLC will judge whether to stop the machine, the system design humanization, let you operate simple, simple.

- The machine is beautiful in appearance, stable in operation and low in noise. This is the most ideal filling and sealing equipment in China.

- The sealing system of the device is sealed with a biaxial structure, and the feed amount of the first and second rolls can be adjusted and controlled separately.

- Adopt Siemens PLC, daida converter, mitsubishi touch screen, YAD solenoid valve and omron proximity switch to ensure the stability and efficiency of the whole machine.

- The machine is widely used for heavy bearing, and imported bearings are used in the key heavy-duty area to prolong the service life and stability.

beer keg filling machine beer keg filling machine beer keg filling machine

| Item | MT-CB330 24-8 |

| Quantity of head for filling and sealing | Filling: 24; Sealing: 8 |

| Capacity | 10000 cans/hour (330 ml can) |

| Air-source pressure | 0.6Mpa |

| Gas consumption | 0.08M3/min |

| Filling temperature | ≤4°C |

| Empty can size | Diameter: 40~120mm |

| Empty can height | 40~175mm |

| Filling precision | ±5mm(liquid level fixed) |

| Filling type | Isobaric Filling |

| Power of main motor | 3.7KW |

| Rated voltage | 380V |

| Outer dimension | 2400×1500×1900mm |

| Weight | 3000kg |

Product Show:

Output Product

free 2 years spare parts replacement services, and it is free of cvharge, in addition we also provide comprehensive after-sale technical support service for you!

Q: what are the characteristics of our company?

A: we provide turnkey projects, including pre-sales and after-sales services; Complete production line equipment supply; Bottle design; Provide the layout plan; Or provide information on purchasing agent suppliers for auxiliary materials; Equipment overseas installation and commissioning; Operator training and so on, make sure you use the equipment at ease, rest assured, save the heart!

Contact Us

Send us inquery now,our professional team will contact with you with business proposal for your business!

-

Industrial Small Bottled Beverage Filling Line High Capacity 5000-20000 BPH

Industrial Small Bottled Beverage Filling Line High Capacity 5000-20000 BPH

The beverage filling production line is mainly used for was...

→ -

7000-12000 BPH Automatic Bottle Filling Machine / Complete Beverage Production Line

7000-12000 BPH Automatic Bottle Filling Machine / Complete Beverage Production Line

The machine is developed by our company independently, it ...

→ -

Small Bottle Beverage Filling Line Juice Energy Drink Soda Water Filling Machine

Small Bottle Beverage Filling Line Juice Energy Drink Soda Water Filling Machine

3 in 1 beverage filliing Machine is mainly used for the f...

→ -

Round Square PET Bottle Filling Machine , 3000-6000 BPH Beverage Filling Equipment

Round Square PET Bottle Filling Machine , 3000-6000 BPH Beverage Filling Equipment

this production line is widely used for filling all kinds o...

→