Products

-

Bag Filling Machine

-

Beverage Filling Line

-

Biscuit Making Machine

-

Biscuit Production Line

-

Bottle Blowing Machine

-

Carbonated Drink Production Line

-

Cosmetic Filling Machine

-

Drink Production Line

-

Drinking Water Filling Machine

-

Drinking Water Production Line

-

Edible Oil Production Line

-

Fruit Juice Processing Line

-

Juice Filling Machine

-

Plastic Injection Molding Machine

-

Snack Food Production Line

-

UHT Milk Processing Line

-

Water Treatment Systems

-

Vertical Packaging Machine

-

Other Packaging Machine

-

Pillow Type Packaging Machine

-

Pre-made Pouch Packing Machinery

-

Measuring Equipment

-

Cup Filling Machines

-

Conveyor Equipment

-

Auxiliary Equipment

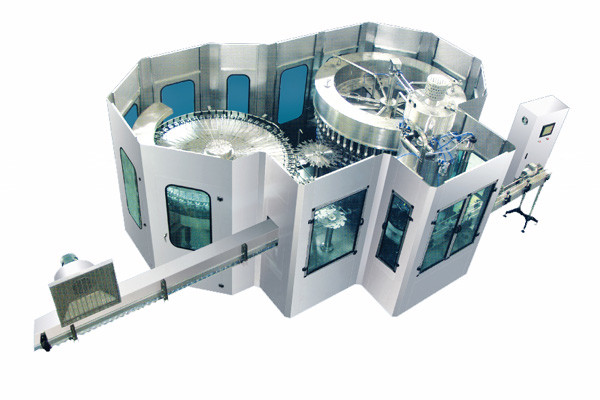

Monoblock carbonated drink rinsing filling capping machine

Rinsing, Filling And Capping Monoblock Machines

The rinsing, filling, and capping monoblock machine is an advanced piece of equipment specifically designed for mineral water, beverage, beer, and juice production plants. It integrates three essential functions into one unit.

Carbonated Drinks Monoblock Rinsing/Filling/Capping

Range of carbonated filling machines for carbonated soft drinks and water Rinsing, filling and capping on a single base structure ensures a small footprint, saving much needed floorspace. Different filling and capping configurations available to suit production output demand.

Monoblock Rinsing-Filling-Capping Machine - Focus on pack

Fill-to-level filling for water and non-carbonated drinks, counter pressure filling for carbonated soft drinks, hot filling for juice, beverage, tea, low vacuum filling for milk and yogurt.

Mono Block | Rotary Rinser, Filler, and Capper Mono Blocks

The Accutek Mini Monoblock Systems are robust continuous rotary monoblock systems designed to simplify your bottling line by combining the bottle filler, tip/plug placer, and capper into a single space-saving machine.

Rinser/Filler/Capper Monoblocks - Bottling Systems ...

It includes automatic and semi-automatic machines for every type of rinsing, filling and capping of glass or PET bottles. We also cater for aluminium cans & bottles, for carbonated or non-carbonated liquids. Throughputs range from 500 to 16,000 bph. We can offer free standing bottle rinsers.

Rinser/Filler/Capper Monoblocks - IC Filling Systems

It includes automatic and semi-automatic machines for every type of rinsing, filling and capping of glass or PET bottles. We also cater for aluminium cans & bottles, for carbonated or non-carbonated liquids.

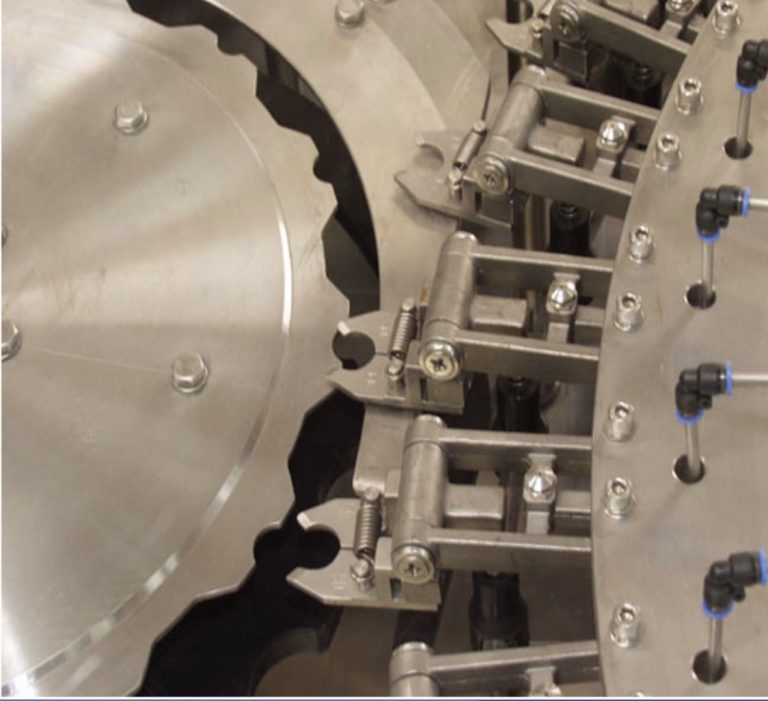

Automatic monoblock carbonated water filling machine

4-in-1 filling monoblock, combined with rinsing, filling, screw capping and ROPP capping. It is innovated and designed in the requirement of isobaric filling for carbonated drinks, beer, sparkling water, etc.

Monoblocks for rinsing, filling, capping - Linker Group

Isobaric fillers P-RFC are designed for filling carbonated beverages into PET and glass bottles. The cycle of operation of machines includes rinsing, filling and capping/crowning. Size range 24 to 96 filling valves with capacity up to 900 bottles (0,5L) per minute.

3-in-1 Monoblock Carbonated Drink Filling Line / Machine

3-in-1 Automatic Carbonated Beverage Bottling Machine Monoblock Rinser, Filler and Capper for Soft Drinks. This series of monoblock bottling machine is suitable for filling all kinds of carbonated drinks into PET or glass bottles.

Monoblock | Filling and Capping Machines - Antonio Mengibar

The Monoblock is the all-in-one solution for any liquid filling and capping process. This equipment combines two or more liquid filling and capping operations in one single machine base and assures traceability of each bottle while it is inside of the Monoblock.