Live Chat

Click the buttonMulti Functional Dog Biscuit Making Machine Turnkey Project For Dog / Cat

Alloy (38CrMoAL) screw made by nitriding procedure, high power and wear-resting. Self-cleaning ability, convinient operation with no need to uninstall or clean the barrel and screw when roasting or changing of materials. Implementing speed-adjusted converter on raw material-giving system, extrusion procedure and cutting processing.

Products

-

Bag Filling Machine

-

Beverage Filling Line

-

Biscuit Making Machine

-

Biscuit Production Line

-

Bottle Blowing Machine

-

Carbonated Drink Production Line

-

Cosmetic Filling Machine

-

Drink Production Line

-

Drinking Water Filling Machine

-

Drinking Water Production Line

-

Edible Oil Production Line

-

Fruit Juice Processing Line

-

Juice Filling Machine

-

Plastic Injection Molding Machine

-

Snack Food Production Line

-

UHT Milk Processing Line

-

Water Treatment Systems

-

Vertical Packaging Machine

-

Other Packaging Machine

-

Pillow Type Packaging Machine

-

Pre-made Pouch Packing Machinery

-

Measuring Equipment

-

Cup Filling Machines

-

Conveyor Equipment

-

Auxiliary Equipment

| Model Number: | LT65,LT70.LT85,LT90 | Application: | Commercial Biscuit Making Machine |

|---|---|---|---|

| Voltage: | 380V/50HZ/Three Phase, 220V/50HZ/Single Phase Or Change As Rquired | Power(W): | 120W,164W |

| Weight: | 1200kg | Dimension(L*W*H): | Max: 30000X3500X4300 |

| Warranty: | 1year's | Capacity: | 1000-1200kg/h |

| Main Motor: | SIEMENS (CHINA) | Electronic Parts Brand: | FUJI And LG |

| Inverter Brand: | DELTA | Relay: | OMRON |

| Trial Demonstration: | Welcome You To Visit Us At Any Time For Machinery Demonstration |

Easy Operation,Multifunctional Turnkey Project Dog Biscuits Making Machine For Dog,Cat,Fox,bird,fish

Product Description

As the growing numer of pets, international pet foods market becomes very big . To be able to meet various feeding requirements, our Company have developed this machine for worldwide market ,bellow is the advantage of our production line :

- Convenient operation,

- User-friendly human inerface machine

- Precise control to make sure the food can easily be manufactured under stable temperature, pressure and other circumstance.

- Multi-function with wide range raw material of Dog Biscuits Making Machine,including meat meal, fish meal, bone powder, corn powder, soya meal and other grains’ powder,it produce the innovative shapes, high nutritional and savory taste pet food for dog, cat, fox, bird etc and also floating or sinking aquatic feed for fish or shrimp etc.

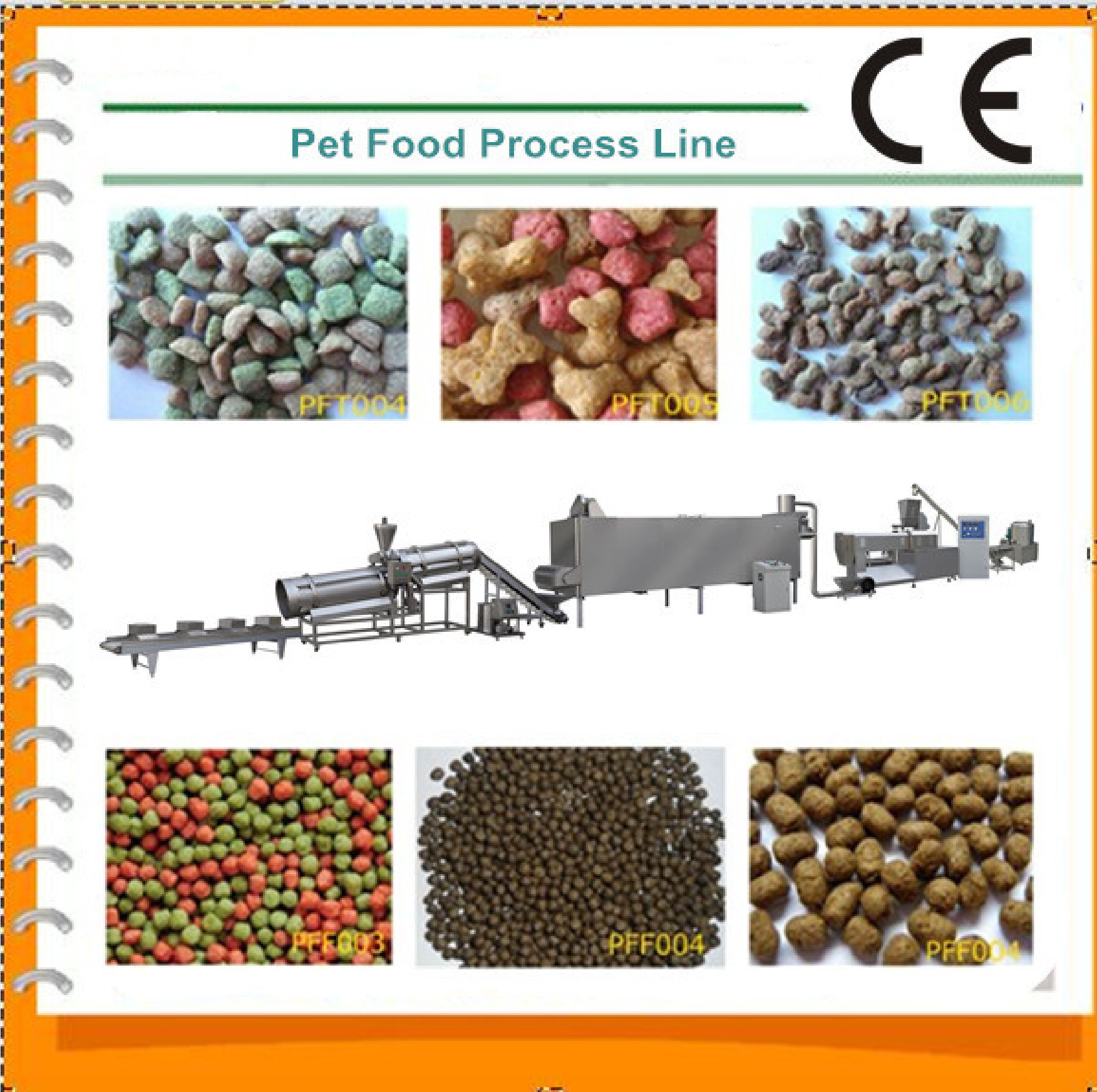

Output Production Pictrue

Dog Biscuits Making Machine Technical Specification

| Model | Installed Power | Power Consumption | Output | Size (L*W*H) | |

| MT-LT65 Pet Food Processing Line | 80kw | 56kw | 120–150kg/h | 22500x1200x2200mm | |

| MT-LT70 Pet Food Processing Line | 128kw | 90kw | 200-250kg/h | 25000x1500x2200mm | |

| MT-LT85 Pet Food Processing Line | 175kw | 123kw | 500-700kg/h | 30000x3500x4300mm | |

| MT-LT90 Pet Food Processing Line | 220kw | 154kw | 1000-1200kg/h | 32000x2400x3000mm | |

1. Alloy (38CrMoAL) screw made by nitriding procedure, high power and wear-resting. Self-cleaning ability, convinient operation with no need to uninstall or clean the barrel and screw when roasting or changing of materials.

2. Implementing speed-adjusted converter on raw material-giving system, extrusion procedure and cutting processing.

3.Food grade stainless steel to keep it clean and no secondary polution ,twin screw feeding device, stable materials feeding in the whole food processing.

3. Gearbox with automatic lubrication function, extending gear life.

4. Increased radiator on driving part for forced cooling effect, ensuring extruder operates safely.

5. Barrel with water-cooled circulation, raw materials not only for corn/rice, also for wheat flour/starch with high viscosity. Different moisture-extrusion temperature ratio, whole-expanded and half expanded as different type of products. 6. Cutting knife fixed in the die head seat, rotary cutting by V-belt drive.

We Provide Satisfied Service & Turnkey Solution

1.) Consultation service before, during,and after sales;

2.) Project planning and design service;

3.) Debugging of equipment until everything works perfect;

4.) supervise the equipments' in long distance shipping from seller's factory to the named place by buyer;

5.) Perfect Installation, training. ,maintenance and operating personally;

6.) New production techniques and formulas;

7.) Provide 1 year complete warranty and life-time maintenance service.

-

Soft And Hard Biscuit Processing Line , Commercial Automatic Cookie Making Machine

Soft And Hard Biscuit Processing Line , Commercial Automatic Cookie Making Machine

This series of biscuit production line is mainly used to pro...

→ -

Automatic Wafer Biscuit Making Equipment / Walnut Sweet Cake Molding Machine

Automatic Wafer Biscuit Making Equipment / Walnut Sweet Cake Molding Machine

The walnut cake machine is mainly used for production of wal...

→ -

Industrial Biscuit Making Machine 20 – 100 Pcs / Min Full Automatic Multi Function

Industrial Biscuit Making Machine 20 – 100 Pcs / Min Full Automatic Multi Function

Multi-function filling, molding, cutting and making of vario...

→ -

Snack Cookies Biscuit Production Machine , Wafer Biscuit Production Line For Corn Rice

Snack Cookies Biscuit Production Machine , Wafer Biscuit Production Line For Corn Rice

Automatic Small Snack Cookies Biscuit Making Machine by corn...

→