Live Chat

Click the buttonStainless Steel Carbonated Drink Filling Line High Capacity Automatic For Pure Water

it cost is suitable for various kinds of PET bottles, such as mineral water, fruit drinks, milk, in 0.25 l – 2 l bottle shape size range, the yield can reach stable production 2000-36000 PCS, our PET bottle water filling machine pure water production line adopts the SS316, SS304 stainless steel material, and passed the CE SO9000 agreement, product quality supervision is rigorous, strict production process and specification, make sure you are able to provide customers with high quality products

Products

-

Bag Filling Machine

-

Beverage Filling Line

-

Biscuit Making Machine

-

Biscuit Production Line

-

Bottle Blowing Machine

-

Carbonated Drink Production Line

-

Cosmetic Filling Machine

-

Drink Production Line

-

Drinking Water Filling Machine

-

Drinking Water Production Line

-

Edible Oil Production Line

-

Fruit Juice Processing Line

-

Juice Filling Machine

-

Plastic Injection Molding Machine

-

Snack Food Production Line

-

UHT Milk Processing Line

-

Water Treatment Systems

-

Vertical Packaging Machine

-

Other Packaging Machine

-

Pillow Type Packaging Machine

-

Pre-made Pouch Packing Machinery

-

Measuring Equipment

-

Cup Filling Machines

-

Conveyor Equipment

-

Auxiliary Equipment

| Type: | Automatic Soda Filling Machine | Application: | Apparel, Beverage, Chemical, Commodity, Food, Machinery & Hardware, Medical, Textiles, Pet Bottle Water Filling Machine Pure Water Production Line |

|---|---|---|---|

| Automatic Grade: | Automatic | Driven Type: | Hydraulic |

| Voltage: | 220V 380V 440V | Material: | 316L+304 Stainless Steel |

| PLC: | Mitsubishi – Japan(According To Customer's Requirements) | Processing Types: | Pet Bottle Water Filling Machine Pure Water Production Line |

Stainless Steel High Capcity Autoamtic pet bottle carbonated drink processing line / carbonated drink filling line cost

Product Description

Stainless Steel High Capcity Autoamtic pet bottle carbonated drink processing line / carbonated drink filling line cost is suitable for various kinds of PET bottles, such as mineral water, fruit drinks, milk, in 0.25 l – 2 l bottle shape size range, the yield can reach stable production 2000-36000 PCS, our PET bottle water filling machine pure water production line adopts the SS316, SS304 stainless steel material, and passed the CE SO9000 agreement, product quality supervision is rigorous, strict production process and specification, make sure you are able to provide customers with high quality products

Main equipments:

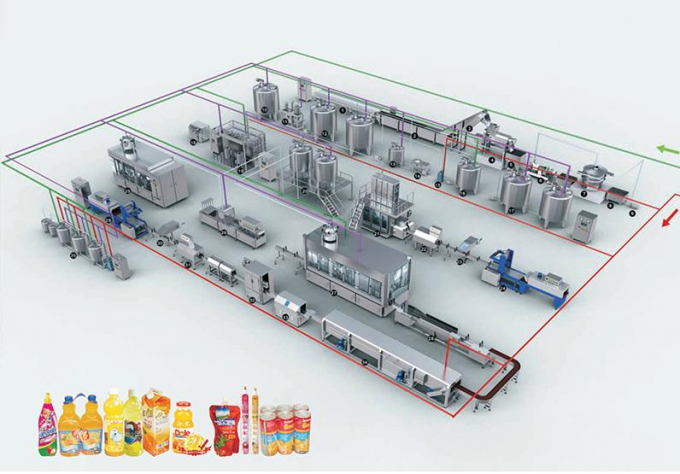

juice extractor, water treatment plant, CIP cleaning system, sterilization machine, mixing tank, filling equipment.

Product Features:

- Smart mitsubishi touch screen, humanized design, simple and smooth operation.

- The equipment adopts high speed filling valve to avoid leakage and accurate filling quantity.

- The device adopts program logic controller (PLC), easy to set parameters and easy to operate.

- The pneumatic components are famous brand (usually Siemens, omron, etc.), stable and reliable.

- Intelligent system self-protection system, can feel pneumatic linkage control, and lack of automatic bottle protection equipment.

- Pneumatic control valve, efficient and safe.

- Tight positioning design, easy to adjust, suitable for the packaging of bottles of all sizes.

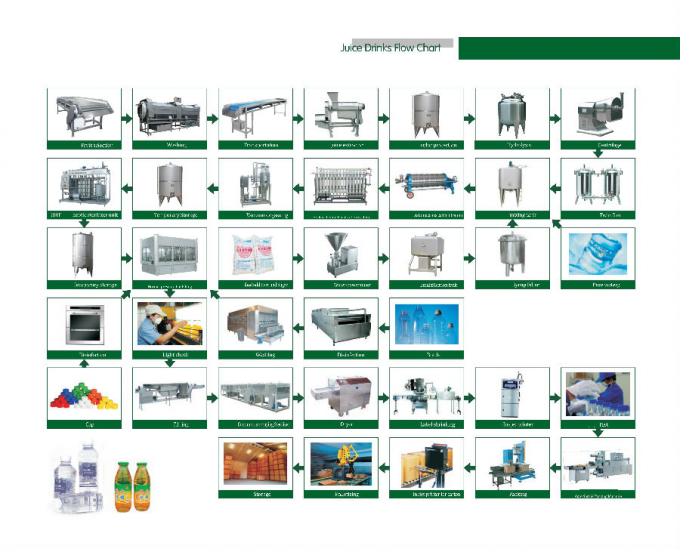

Flow Chart:

We are able to supply whole production line for carbonated drinks ,Send us now We will make a business proposal for you with professional advice of business.

Product Show:

|

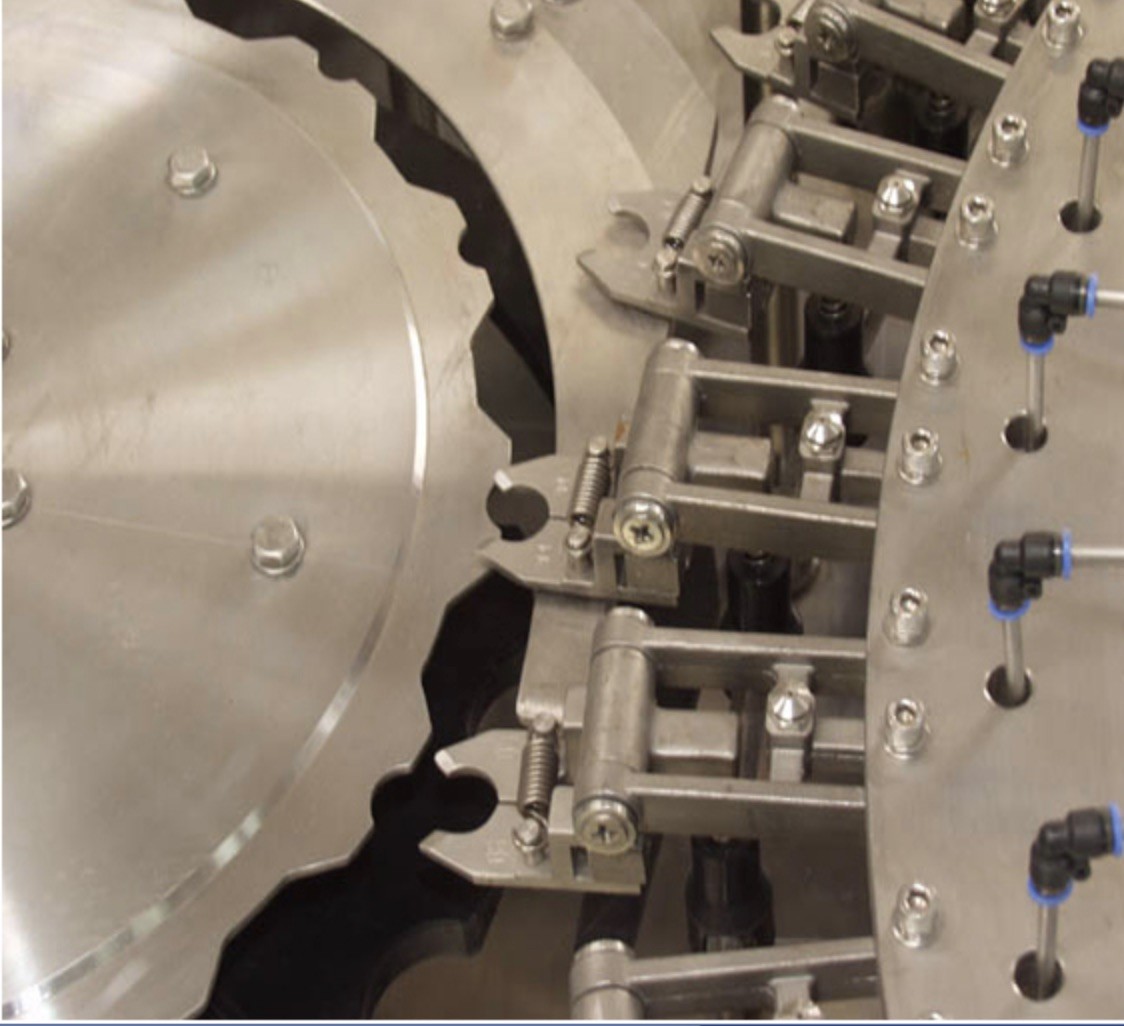

Rinsing Parts:

|

|

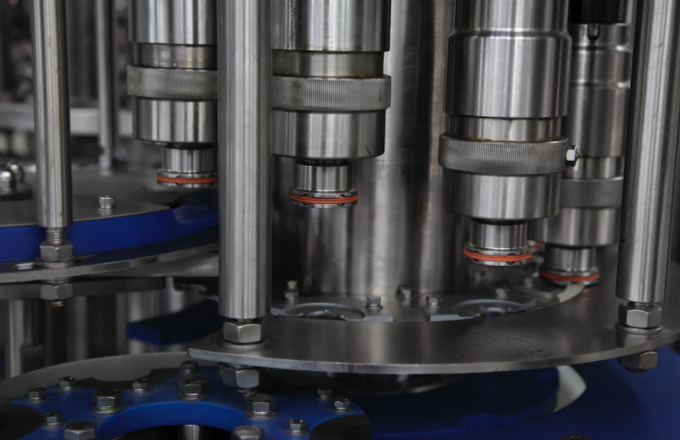

Filling Parts:

|

|

|

Capping Parts: Raw material: Food Grade Stainless Steel SUS304 Capping type: Rotary screw capping Adopts Italy advanced technology, more stable and durable. |

|

PLC and Touch Screen Brand: Siemens Original: Japan Using international brand electrical components to ensure machines running in good condition for longer time. |

|

|

high position tank made of high quality SUS304. |

high quality reflow tank for beverage juice |

Secifications:

| Technical parameters | 8/8/3 | 18-18-6 | 24-24-8 | 32-32-10 |

| Production capacity (500ml)(B/H) | 3000 | 6000 | 10000 | 14000 |

| Bottle washing station | 2 | 2.5 | 5 | 6 |

| Drying station | 2 | 3.5 | 6 | 10 |

| PET bottle size (mm) | D=60~97mm | |||

| H=150~320mm | ||||

| Capping torque (N.m) | 0.6~2.8 | 0.6~2.8 | 0.6~2.8 | 0.6~2.8 |

| Installed capacity (Kw) | 2.38 | 2.38 | 4.18 | 4.18 |

| Compressed Air consumption(0.6Mpa)Nm3/min | 0.5 | 0.5 | 0.6 | 0.8 |

| Washing bottles water consumption(0.2-0.25Mpa)m3/h | 1.5 | 1.5 | 1.5~2 | 1.5~2 |

| Dimension(L*W*H)(mm) | 2300*2000*2850 | 2500*2000*2850 | 2800*2300*2850 | 4150*2560*2850 |

| Weight(t) | 4 | 4.5 | 6 | 7 |

Configurations

| Machine frame | SUS304 and SUS316L Stainless steel | |

| Peristaltic pump | WATSON MARLOW Peristaltic pump (UK) | |

| Main Motor | ABB | Switzerland |

| Inverter | Mitsubishi | Japan |

| Valve | Festo | Germany |

| Air Switch | Schneider | France |

| Contactor | Schneider | France |

| Relay | Omron | Japan |

| OFA | Autonics | Korea |

| Bearing | IGUS | Germany |

| Turntable | Plastic POM | Japan |

| Cylinder | AIRTAC | Taiwan |

| Touch screen | Siemens | Germany |

| PLC | Siemens | Germany |

| Servo motor | Delta | Taiwan |

It is these high quality components that help our machines achieve market leadership when compared with other domestic machines of the same type.

Output Product

Our Service

.

- After-sales service: we provide 2-year warranty. If you have any problems within 2 year, please contact us immediately.

- We are always at your offer lifetime maintenance and technical support, such as machine or spare parts if you have any question, please feel free to contact us, within a year of issue, we will provide free accessories for you, to make sure that you can use normally.

- Teaching service: our engineers will be after the installation and commissioning period for your staff training, training the main content for the equipment configuration, production process and specification, to ensure that your staff can operate it normally when necessary.

- We have well-known brands of equipment accessories, ensure the quality of the equipment, processing production line in strict accordance with the ISO9001 standard for assembly, so our equipment in full compliance with GMP and ISO standards of production, and through the CE certification, according to the customer's requirements, we can free provide relevant certificate to the customer.

Package

Q&A

Frequently asked questions

Q: are you a manufacturer?

B: yes, we are an experienced machinery manufacturer . The factory is locaed in Shanghai city china. Welcome to visit.

How do I know the quality of your machines?

Answer: you can send us the bottle sample, and we will debug the equipment, ande send the video of running equipment, after you confirm the quality, you can pay the remain payment ,we will delviery.

Q: What certificates do you have?

Answer: according to GMP and ISO standard production, and through CE certification.

Q: what is your quality assurance?

Two years warranty, two years free supply of spare parts, lifelong maintenance and technical support.

Contact Us

Send us inquery now !we will send you best quotation with latest promotion in 12hours!

-

Stainless Steel Wine / Zobo Drink Filling Machine , Beverage Bottling Equipment

Stainless Steel Wine / Zobo Drink Filling Machine , Beverage Bottling Equipment

This machine is used in beverage and food industry. It is us...

→ -

2000 – 18000 BPH Automatic Water Filling Machine , Commercial Fruit Juice Production Line

2000 – 18000 BPH Automatic Water Filling Machine , Commercial Fruit Juice Production Line

New bottled tea beverage production line/juice filling machi...

→ -

Fizzy Drink Production Line / Bottling Machine 6000 BPH-12000 BPH CE Certificate

Fizzy Drink Production Line / Bottling Machine 6000 BPH-12000 BPH CE Certificate

The bottle part adopts the belt conveyor system, which can a...

→ -

Energy Drink Production Line Electric Driven For Beverage High Efficiency Low Energy

Energy Drink Production Line Electric Driven For Beverage High Efficiency Low Energy

This series equipment is used for energy drinks, water, and ...

→