Products

-

Bag Filling Machine

-

Beverage Filling Line

-

Biscuit Making Machine

-

Biscuit Production Line

-

Bottle Blowing Machine

-

Carbonated Drink Production Line

-

Cosmetic Filling Machine

-

Drink Production Line

-

Drinking Water Filling Machine

-

Drinking Water Production Line

-

Edible Oil Production Line

-

Fruit Juice Processing Line

-

Juice Filling Machine

-

Plastic Injection Molding Machine

-

Snack Food Production Line

-

UHT Milk Processing Line

-

Water Treatment Systems

-

Vertical Packaging Machine

-

Other Packaging Machine

-

Pillow Type Packaging Machine

-

Pre-made Pouch Packing Machinery

-

Measuring Equipment

-

Cup Filling Machines

-

Conveyor Equipment

-

Auxiliary Equipment

Automatic RO Water Treatment Plant , Stainless Steel Water Treatment Equipment

Litchi / Pulp Juice Filling Machine High Capacity Semi- Automatic CE Certificate

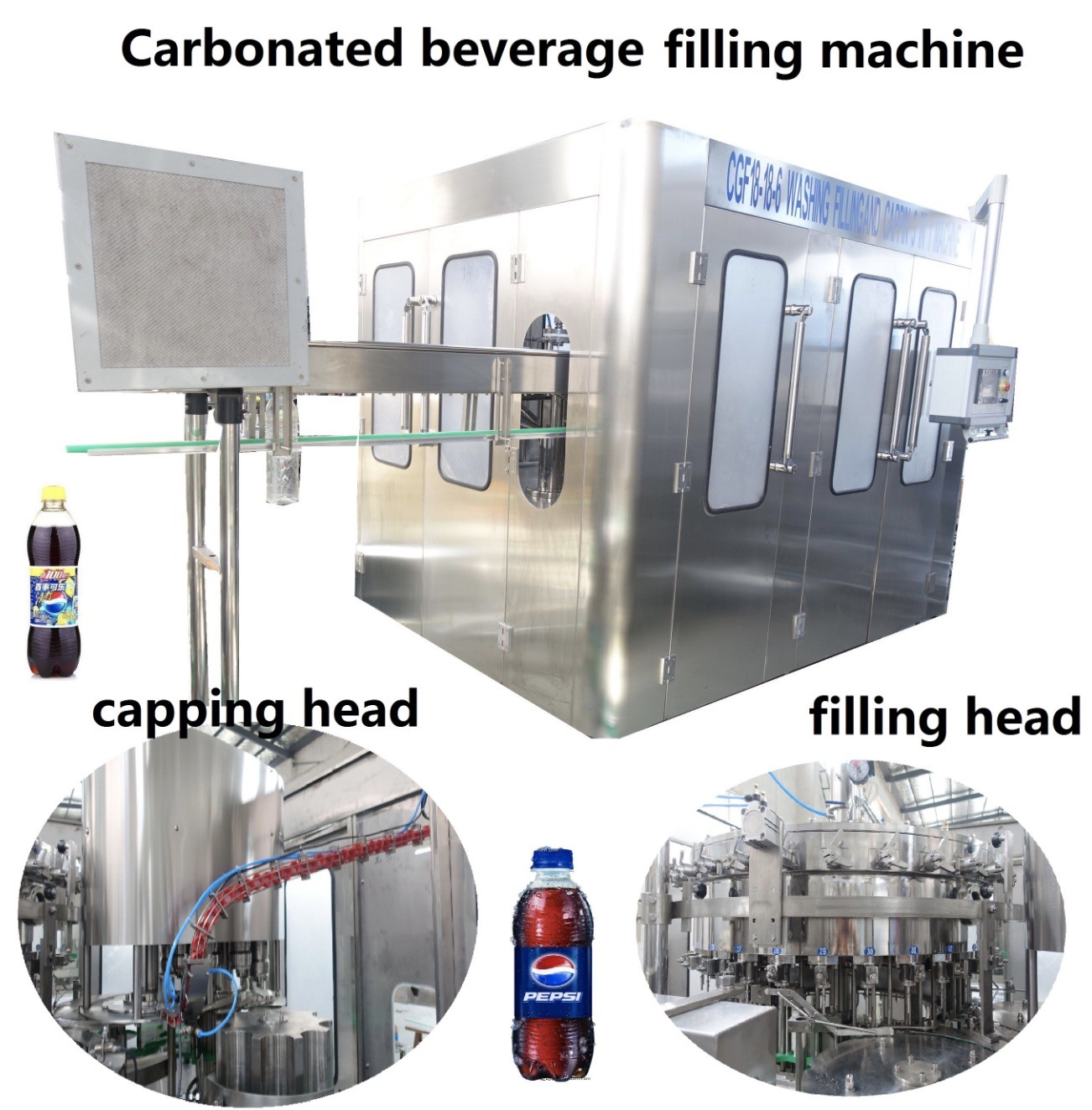

High Capacity Carbonated Drink Production Line Machine For 500ml-2500ml Bottle

3 In 1 Plastic Bottle Beverage Filling Machine , Automatic Soft Drink Filling Machine

Red Bull Energy Drink Production Line Automatic For Glass / PET Bottle

Fully Automatic Drinking Water Filling Machine 600-3000BPH For 5 Gallon PET Bottle

Bottled Mineral Drinking Water Production Machine / Filling Production Line

SUS304 PET Bottle Edible Oil Bottle Filling Machine For Non Viscous Liquid Filling

To Be Run Stable Soft Drinkings Carbonated Filling Machine

Steps In Carbonated Drink Filling Machine Operation

The carbonated beverage filling process is a critical step in the production of fizzy drinks like soda, sparkling water, and energy drinks. Advanced filling machines employ sophisticated technology to ensure precise measurement, optimal carbonation, and consistent quality.

Working Principle of Carbonated Soft Drink Filling Machine

The working principle of a Carbonated Soft Drink Filling Machine is a blend of precision engineering and scientific understanding. From CO2 pressurization to maintaining carbonation levels and ensuring hygiene, every step is meticulously orchestrated to create the beloved fizzy beverages we enjoy.

Carbonated Soft Drink Filling Machine: Working Principle and ...

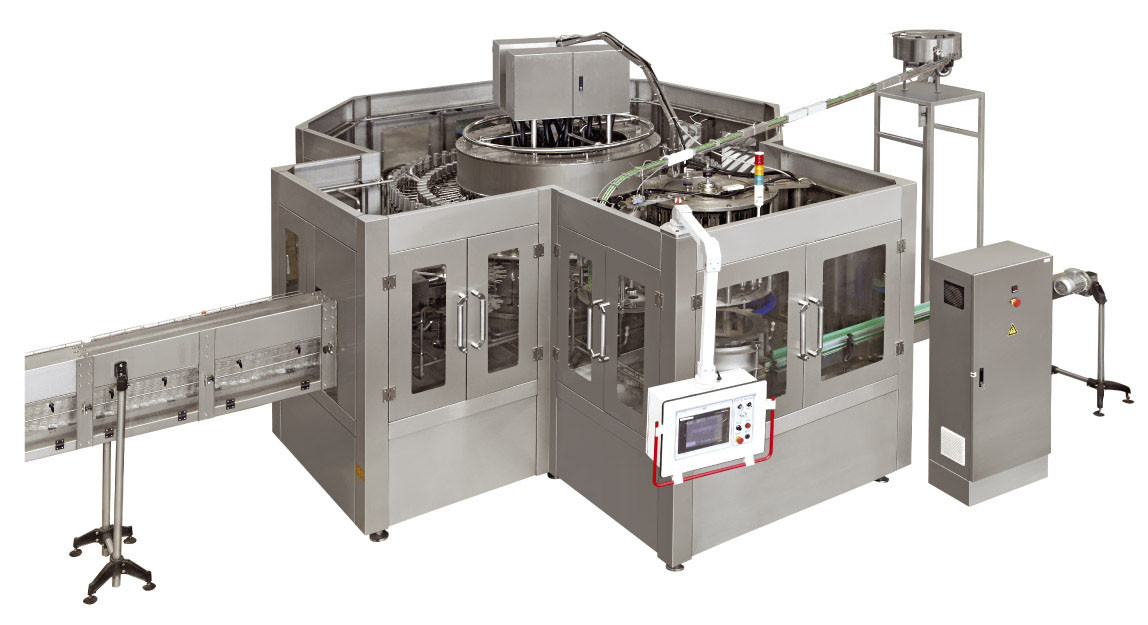

Carbonated beverage filling machine are sophisticated pieces of equipment designed to efficiently fill bottles or cans with carbonated beverages. Their intricate mechanisms and precise operation ensure the consistent quality and integrity of carbonated drinks.

Carbonated Soft Drink (CSD) Filling Machine | HZM Beverage ...

These machines are designed to handle the specific requirements of carbonated beverages, including maintaining proper carbonation levels, preventing foaming, and ensuring accurate filling to avoid spillage and wastage.

The Ultimate Carbonated Beverage Filling Machine

The carbonated soft drink filling machine has versatile applications that allow it to handle a wide range of carbonated beverages: Cola, juices, and sodas – The machine can smoothly fill these classic carbonated soft drinks while minimizing foaming.

How To Choose The Right CSD Beverage Filling Machine

The filling machine must be capable of precisely filling still and carbonated beverages and offering rapid changes. It uses modules with demonstrated dependability and efficiency, delivering up to 98% efficiency and filling PET bottles with precision at up to 10,000 bottles per hour (BPH).

Carbonated Beverage Filling Machine & CSD Filler-FESTA

If your soft drink business is going well, then you need a FESTA DCGF24-24-8 fully automatic carbonated soft drink filler. The use of a new man-machine interface, compact structure, low energy consumption and stable product quality will help you increase your market share.

Unpacking the Fizz: An Insight into the Carbonated Drinks ...

Investing in a top-tier carbonated drink filling machine can be transformative for beverage producers, offering several key benefits: Optimized Efficiency: High-speed machines can significantly increase output, reducing downtime and enhancing productivity.

Carbonated soft drink filling machine - Comac

Microbrew 20-4 is a carbonated soft drink filling machine able to fill up to 12,000 CPH. It is one of the top-seller compact solutions for the craft micro-brewing market, in fact it is especially designed to provide premium equipment to small & medium-sized breweries.

Effortless Bottling with Advanced Carbonated Soft Drink ...

Precision in Carbonation Control: These advanced systems of carbonated soft drink filling ensure that each soft drink is infused with the exact amount of carbonation, delivering a consistent and satisfying effervescence in every bottle.