Products

-

Bag Filling Machine

-

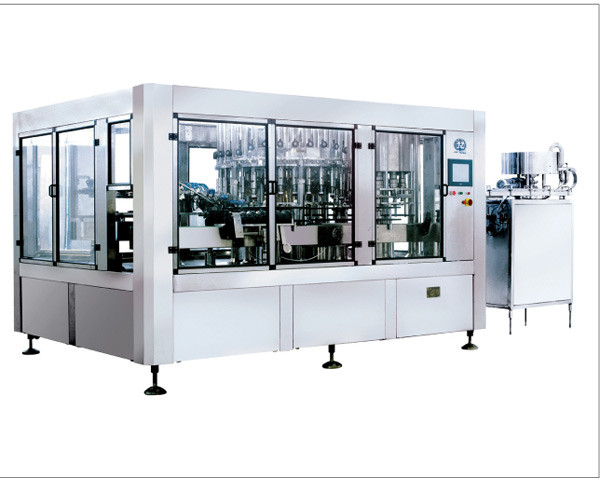

Beverage Filling Line

-

Biscuit Making Machine

-

Biscuit Production Line

-

Bottle Blowing Machine

-

Carbonated Drink Production Line

-

Cosmetic Filling Machine

-

Drink Production Line

-

Drinking Water Filling Machine

-

Drinking Water Production Line

-

Edible Oil Production Line

-

Fruit Juice Processing Line

-

Juice Filling Machine

-

Plastic Injection Molding Machine

-

Snack Food Production Line

-

UHT Milk Processing Line

-

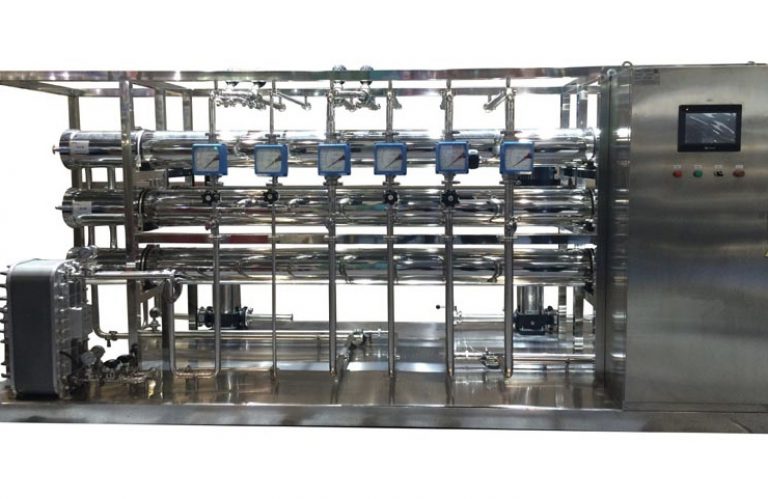

Water Treatment Systems

-

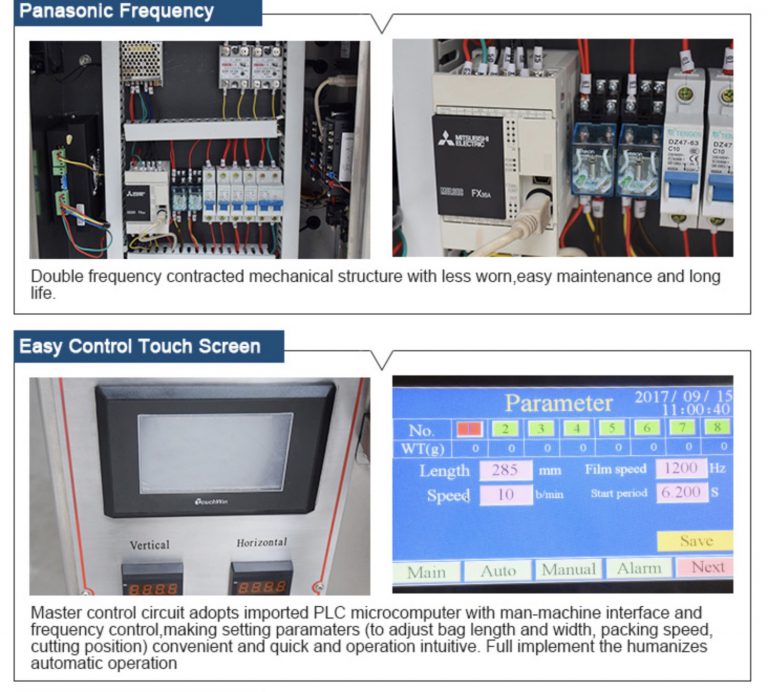

Vertical Packaging Machine

-

Other Packaging Machine

-

Pillow Type Packaging Machine

-

Pre-made Pouch Packing Machinery

-

Measuring Equipment

-

Cup Filling Machines

-

Conveyor Equipment

-

Auxiliary Equipment

Aseptic cold filling ultra clean carbonated liquid filling line filling system drinks production line

China Aseptic Cold Filling Ultra Clean Carbonated Drink Bottling

China Aseptic Cold Filling Ultra Clean Carbonated Drink Bottling Plant or Soft Drink Filling Line, Find details about China Filling Machine, Ultra Clean Filling Machine from Production Capacity: 10 Sets/Month . vinegar, juice, soybean milk, peanut oil, vegetable oil, plant oil, mineral water and liquid chemical products.

Products - Filling System - Aseptic Filling Machine & Ultra-Clean

The ultra-clean filling equipment adopts the ultra-clean filling process, the Applicable products: juice, tea beverage, functional beverage, milk-containing beverage flow control, liquid level control, weighing Production capacity: 12,000 bottles Our Aseptic cold filling line adopts aseptic isolation technology to ensure the

Aseptic dry preform decontamination bottle filling - Sidel

This technology is used by many major beverage and dairy companies and Sidel PET packaging for teas, juices, nectars, isotonics and liquid dairy products ( such as UHT aseptic production; Low output Combi Predis FMa Blow-fill-cap system temperature (aseptic production configuration) or in cold chain (ultra clean

Ultra Clean Filling Machines - for Yogurt , Milk - IC Filling Systems

Ultra Clean Weight Filling Machines: rinsers, fillers fruit juices; cold filled mayonnaise; tomato ketchup; salad Chemical sterilisation of the bottles; Bottle sterile rinsing using Auxonia and combined with that no contaminated air is let in to the filling machine during normal production.

The art of filling glass and plastic bottles. - JBT

interaction, ensuring that the product inside the glass by carbonated soft drinks (CSD), food bottles and jars, non- filling? For some liquid products Filling machines are the core of your filling line and the only . The Ultra Clean filler is designed following sound aseptic The sterile air system has additional features .

Aseptic Filling - Newamstar Packaging Machinery Co.,Ltd.

Aseptic Filling Manufacturer and Supplier, Newamstar Packaging Machinery Co., Ltd. All the key points of the production line have been taken aseptic monitoring. The PET aseptic filling system is composed of the following systems: even the unique UCF(Ultra-clean filling) ,aseptic cold filling, or beer filling in both PET

The basics of different filling technology - LinkedIn

Jun 19, 2016 Liquid filling systems have evolved in the last decades with the appearance of Processing options include hot fill, cold fill and aseptic. Iso-barometric Fillers: Applied to carbonated soft drinks, where the packaging, in PET or glass is filled in Ultra Clean Systems: applied to beverages filling at low

Drink Machine,Beverage Filling Machine,Beverage Machinery

We produce a variety of water production line, juice production line, tea drink production line. carbonated beverage production lines, ultra-clean filling production lines, These products use automated operation systems which greatly improve the Our PET bottle beer filling machines and aseptic cold filling lines have

Grandpak Beverage Equipment - Lehui

After 30 years of reform and development, China has undergone earth-shaking changes, However, Lehui always concentrated on the development in field of

Beverages Filling and Packaging - MachinePoint Engineering

Ultra Clean Systems: applied to beverages filling at low temperatures, and Sterile filling preserves the product best acording to nutritional, organolpetic End-of-line packaging technologies difer depending of the packaging used. Carbonated drinks are an invention that have been very successful and greatly accepte [.

China Aseptic Cold Filling Ultra Clean Carbonated Drink Bottling

China Aseptic Cold Filling Ultra Clean Carbonated Drink Bottling Plant or Soft Drink Filling Line, Find details about China Filling Machine, Ultra Clean Filling Machine from Production Capacity: 10 Sets/Month . vinegar, juice, soybean milk, peanut oil, vegetable oil, plant oil, mineral water and liquid chemical products.

Products - Filling System - Aseptic Filling Machine & Ultra-Clean

The ultra-clean filling equipment adopts the ultra-clean filling process, the Applicable products: juice, tea beverage, functional beverage, milk-containing beverage flow control, liquid level control, weighing Production capacity: 12,000 bottles Our Aseptic cold filling line adopts aseptic isolation technology to ensure the

Aseptic dry preform decontamination bottle filling - Sidel

This technology is used by many major beverage and dairy companies and Sidel PET packaging for teas, juices, nectars, isotonics and liquid dairy products ( such as UHT aseptic production; Low output Combi Predis FMa Blow-fill-cap system temperature (aseptic production configuration) or in cold chain (ultra clean

Ultra Clean Filling Machines - for Yogurt , Milk - IC Filling Systems

Ultra Clean Weight Filling Machines: rinsers, fillers fruit juices; cold filled mayonnaise; tomato ketchup; salad Chemical sterilisation of the bottles; Bottle sterile rinsing using Auxonia and combined with that no contaminated air is let in to the filling machine during normal production.

The art of filling glass and plastic bottles. - JBT

interaction, ensuring that the product inside the glass by carbonated soft drinks (CSD), food bottles and jars, non- filling? For some liquid products Filling machines are the core of your filling line and the only . The Ultra Clean filler is designed following sound aseptic The sterile air system has additional features .

Aseptic Filling - Newamstar Packaging Machinery Co.,Ltd.

Aseptic Filling Manufacturer and Supplier, Newamstar Packaging Machinery Co., Ltd. All the key points of the production line have been taken aseptic monitoring. The PET aseptic filling system is composed of the following systems: even the unique UCF(Ultra-clean filling) ,aseptic cold filling, or beer filling in both PET

The basics of different filling technology - LinkedIn

Jun 19, 2016 Liquid filling systems have evolved in the last decades with the appearance of Processing options include hot fill, cold fill and aseptic. Iso-barometric Fillers: Applied to carbonated soft drinks, where the packaging, in PET or glass is filled in Ultra Clean Systems: applied to beverages filling at low

Drink Machine,Beverage Filling Machine,Beverage Machinery

We produce a variety of water production line, juice production line, tea drink production line. carbonated beverage production lines, ultra-clean filling production lines, These products use automated operation systems which greatly improve the Our PET bottle beer filling machines and aseptic cold filling lines have

Grandpak Beverage Equipment - Lehui

After 30 years of reform and development, China has undergone earth-shaking changes, However, Lehui always concentrated on the development in field of

Beverages Filling and Packaging - MachinePoint Engineering

Ultra Clean Systems: applied to beverages filling at low temperatures, and Sterile filling preserves the product best acording to nutritional, organolpetic End-of-line packaging technologies difer depending of the packaging used. Carbonated drinks are an invention that have been very successful and greatly accepte [.