Live Chat

Click the buttonFull Automatic PET / Glass Bottle Production Line , Carbonated Beverage Filling Machine

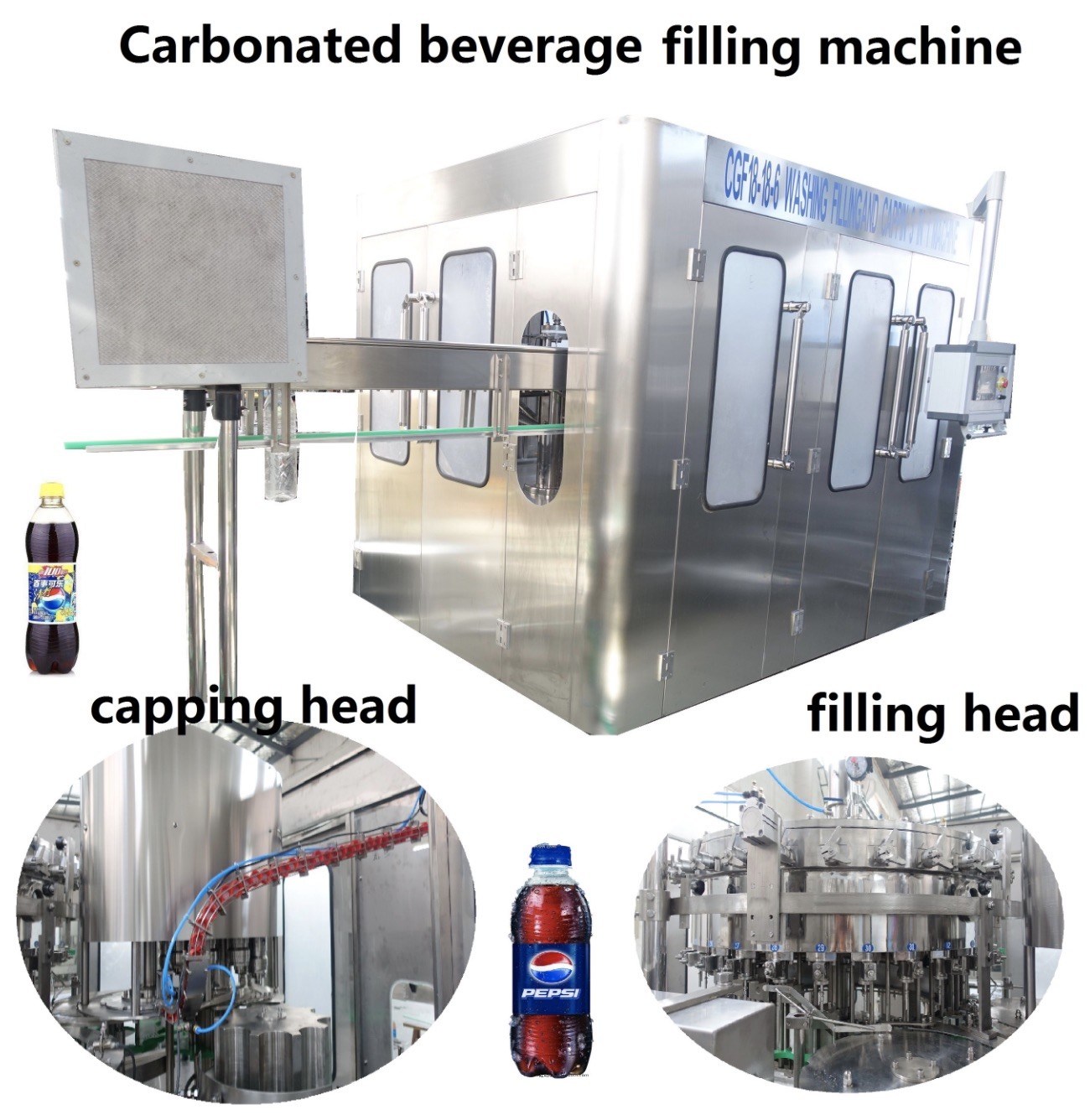

Equipment is mainly used for plastic bottle filling containing carbonated and non-carbonated beverages, will rinse bottle, filling and capping feature set in one device, the whole process adopts PLC intelligent control, perfect and cohesion, and reduced in the middle of the conveyor belt, energy consumption, while reducing the cost and improve the efficiency of production…

Products

-

Bag Filling Machine

-

Beverage Filling Line

-

Biscuit Making Machine

-

Biscuit Production Line

-

Bottle Blowing Machine

-

Carbonated Drink Production Line

-

Cosmetic Filling Machine

-

Drink Production Line

-

Drinking Water Filling Machine

-

Drinking Water Production Line

-

Edible Oil Production Line

-

Fruit Juice Processing Line

-

Juice Filling Machine

-

Plastic Injection Molding Machine

-

Snack Food Production Line

-

UHT Milk Processing Line

-

Water Treatment Systems

-

Vertical Packaging Machine

-

Other Packaging Machine

-

Pillow Type Packaging Machine

-

Pre-made Pouch Packing Machinery

-

Measuring Equipment

-

Cup Filling Machines

-

Conveyor Equipment

-

Auxiliary Equipment

Automatic RO Water Treatment Plant , Stainless Steel Water Treatment Equipment

Litchi / Pulp Juice Filling Machine High Capacity Semi- Automatic CE Certificate

High Capacity Carbonated Drink Production Line Machine For 500ml-2500ml Bottle

3 In 1 Plastic Bottle Beverage Filling Machine , Automatic Soft Drink Filling Machine

Red Bull Energy Drink Production Line Automatic For Glass / PET Bottle

Fully Automatic Drinking Water Filling Machine 600-3000BPH For 5 Gallon PET Bottle

Bottled Mineral Drinking Water Production Machine / Filling Production Line

SUS304 PET Bottle Edible Oil Bottle Filling Machine For Non Viscous Liquid Filling

| Type: | Glass Bottle Filling Machine | Condition: | New |

|---|---|---|---|

| Application: | Apparel, Beverage, Chemical, Commodity, Food, Machinery & Hardware, Medical, Textiles | Packaging Material: | Glass, Metal, Paper, Plastic |

| Automatic Grade: | Automatic | Driven Type: | Electric |

| Machine Capicity: | 2000-24000bph (Customized) | Bottle Volume: | 100-2500ml (Customized) |

| Bottle Type: | Round Or Square | Working Time: | Normally Used 8 To 10 Years |

Full Automatic PET / Glass Bottle Production Line , Carbonated Beverage Filling Machine

Advantages

- All parts that are in contact with the beverage are polished to a smooth, easy to clean surface with a stainless steel surface, and there is no secondary pollution.

- The sealing material is ethylene propylene rubber, which ensures that the seal is sealed and not contaminated by the entry in the air.

- Using PLC as the center control, the pressure transmitter and electromagnetic pneumatic valve are used to measure the liquid level to keep the filling pressure balance, ensuring the stability of the liquid level, high precision and accuracy.

- New filling valve designed for plastic bottle. The backflow air and liquid are insulated in the tank to ensure the cleaning of the filling beverage and to prevent contaminants and bacteria from entering the air.

- Adopt advanced magnet clutch, adjustable torque, ensure safe and reliable cover.

- Spray washing design, save water, cleaner.

Equipment is mainly used for plastic bottle filling containing carbonated and non-carbonated beverages, will rinse bottle, filling and capping feature set in one device, the whole process adopts PLC intelligent control, perfect and cohesion, and reduced in the middle of the conveyor belt, energy consumption, while reducing the cost and improve the efficiency of production…

Technical Parameters

| Model |

CGFR 16-12-6 |

CGFR 18-18-6 |

CGFR 24-24-8 |

CGFR 32-32-10 |

CGFR 40-40-12 |

CGFR 50-50-15 |

| Washing NO | 16 | 18 | 24 | 32 | 40 | 50 |

| Filling NO | 12 | 18 | 24 | 32 | 40 | 50 |

| Capping NO | 6 | 6 | 8 | 10 | 12 | 15 |

| Production Capacity (500ml) | 5000BPH | 6000 | 8000 | 12000 | 15000 | 18000 |

| Install Capacity (kw) | 3.5 | 4 | 4.8 | 7.6 | 8.3 | 9.6 |

| Overall Size |

2450*1800 *2400 |

2650*1900 *2400 |

2900*2100 *2400 |

4100*2400 *2400 |

4550*2650 *2400 |

5450*3210 *2400 |

- To provide customers with pre-project planning workshop and design, to help you design the workshop that is convenient to run, and avoid anti-work.

- The experienced engineers and technicians are responsible for the installation and commissioning of the equipment to ensure the normal production and to solve your superior.

- It has one year's wear parts when the equipment is shipped. In addition, we have prepared sufficient spare parts for inventory, and customers need to repair and repair spare parts at any time, which can be supplied quickly, so that you can not worry about the replacement of parts.

- In order to ensure your technical personnel familiar with the performance of the equipment, correct operation and maintenance procedures, control equipment, provide on-site technical training, to facilitate customers faster familiar with the operation process of equipment at the same time, when faced with common problems to solve

-

Stainless Steel Beverage Filling Line 2000-36000BPH For Glass Bottle

Stainless Steel Beverage Filling Line 2000-36000BPH For Glass Bottle

This machine adopts the advanced liquid level measurement te...

→ -

Round / Square Bottle Beverage Production Equipment , Drinking Beverage Filling Machine

Round / Square Bottle Beverage Production Equipment , Drinking Beverage Filling Machine

The carbonated beverage filler is mainly used for filling ca...

→ -

Stainless Steel Carbonated Drink Production Line Automatic CE Approved

Stainless Steel Carbonated Drink Production Line Automatic CE Approved

Type: Beverage Production Equipment Application: Beverage Pa...

→ -

High Efficient Complete Beverage Filling Line High Capacity 14000 BPH

High Efficient Complete Beverage Filling Line High Capacity 14000 BPH

This series of production lines set washing bottle, filling ...

→