Live Chat

Click the buttonHigh Efficient Complete Beverage Filling Line High Capacity 14000 BPH

This series of production lines set washing bottle, filling and capping, label, packaging, suitable for all kinds of fruit juice drinks, tea drinks hot filling production, at the same time to replace a few parts, can be used for pure water, mineral water filling.

Advanced micro gravity type negative pressure filling principle, filling fast, steady, accurate

Products

-

Bag Filling Machine

-

Beverage Filling Line

-

Biscuit Making Machine

-

Biscuit Production Line

-

Bottle Blowing Machine

-

Carbonated Drink Production Line

-

Cosmetic Filling Machine

-

Drink Production Line

-

Drinking Water Filling Machine

-

Drinking Water Production Line

-

Edible Oil Production Line

-

Fruit Juice Processing Line

-

Juice Filling Machine

-

Plastic Injection Molding Machine

-

Snack Food Production Line

-

UHT Milk Processing Line

-

Water Treatment Systems

-

Vertical Packaging Machine

-

Other Packaging Machine

-

Pillow Type Packaging Machine

-

Pre-made Pouch Packing Machinery

-

Measuring Equipment

-

Cup Filling Machines

-

Conveyor Equipment

-

Auxiliary Equipment

| Type: | Automatic Juice Filling Machine | Condition: | New |

|---|---|---|---|

| Application: | Beverage | Packaging Type: | Bottles |

| Packaging Material: | Plastic | Automatic Grade: | Automatic |

| Driven Type: | Electric | Production Capacity: | 14000BPH |

| Bottle Height: | 150-310mm | Function: | Packaged Drinking Water Filling Machine |

| Suitable Bottle: | PET Bottle With Screw Cap |

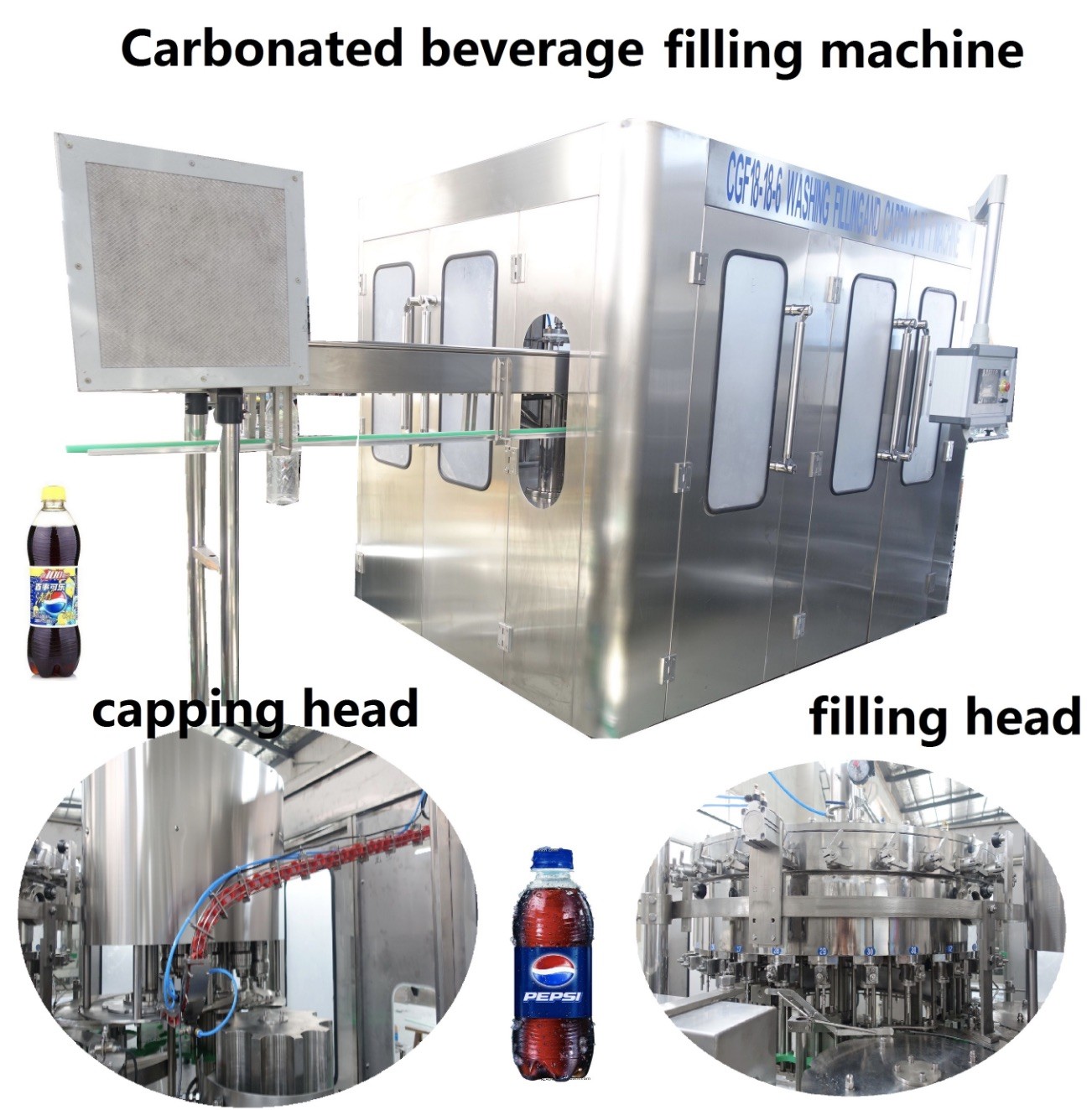

High Capacity Stable Efficient Complete Automatic Bottled Beverage Production Line With CE

Product Description

This series of production lines set washing bottle, filling and capping, label, packaging, suitable for all kinds of fruit juice drinks, tea drinks hot filling production, at the same time to replace a few parts, can be used for pure water, mineral water filling.

Proudct Features

- Advanced micro gravity type negative pressure filling principle, filling fast, steady, accurate,

- it is equipped with perfect material flow system, also can realize independent gas back, back not in contact with the material, reduce the secondary pollution of materials and oxidation.

- This function satisfy the requirements under 95 ℃ hot filling, filling valve and materials in and out of the line without dead Angle

- Equipped with CIP cleaning interface, block is equipped with the bottle before RO water washing device, to ensure that the bottle no moldy phenomenon.Catch is realized by using magnetic torque type screw LIDS, cover, screw cap function.Screw torque stepless adjustable, with functions of constant torque rotary sealing plastic cover.

- Set of standard shrinkage standard machine adopts reciprocating cutter, exclusive design agency steel body combination, movements smooth

- Simple type center guide pin positioning, the specification change more easily, the operator easy to use.

- Pioneered the synchronous belt bottles of DC brushless motor drive.Heat shrinkable packaging from Germany, the packaging combination and bottle type to change the adjustment is convenient, stable performance and excellent packaging.

- The whole machine adopts user-friendly interface touch screen,

- Simenz PLC computer program control and inverter control, advanced technology.

- it Is used for filling cap system automatic control, automatic temperature testing, material high temperature alarm, automatic stop at low temperature and reflux,

- No filling when no bottle lack of bottle waiting, lack of cover downtime, etc.

- Production of 5000-25000 bottles/hour for users to choose.

Product Show

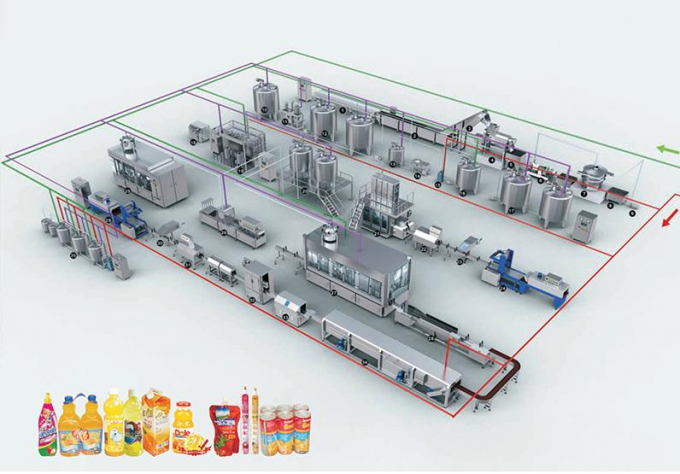

Main equipments:

juice extractor, water treatment plant, CIP cleaning system, sterilization machine, mixing tank, filling equipment.

Flow Chart:

We have professional team to design the whole production line for you ,contact us for more details.

| Model | MT18-18-6 | MT24-24-8 | MT32-32-10 | MT40-40-12 |

| Capacity(BPH) | 6000-8000 | 8000-14000 | 14000-18000 | 18000-20000 |

| Filling Precision | ≤±5mm | |||

| Bottle Standard | Diameter: 50-100, Height: 150-320mm | |||

| Suitable Cap Shape | Plastic Screw Cap | |||

| Water Pressure of Washing | 0.18 Mpa | |||

| Water Consumption for Washing | 1600kg/h | 2500kg/h | 3500kg/h | 7000kg/h |

| Wahsing Position | 16 | 20 | 32 | 40 |

| Filling Position | 16 | 20 | 32 | 40 |

| Capping Position | 8 | 8 | 10 | 12 |

| Gas Consumption (M3/Min) | 0.3 | 0.4 | 0.5 | 0.6 |

| Total Power (KW) | 5.03 | 6.57 | 8.63 | 9.63 |

| Total Weight (KG) | 3500 | 5500 | 6000 | 8000 |

| Dimension(L*W*H) | 2450*1800*2200 | 2750*2180*2200 | 3500*2200*2200 | 3500*2200*2200 |

Product Show:

|

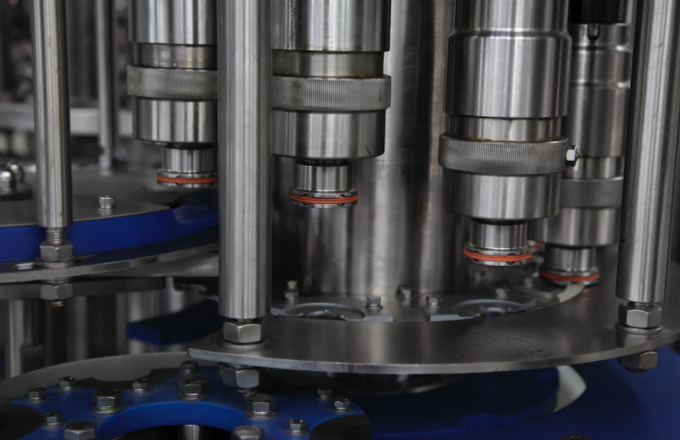

Rinsing Parts:

|

|

Filling Parts:

|

|

|

Capping Parts: Raw material: Food Grade Stainless Steel SUS304 Capping type: Rotary screw capping Adopts Italy advanced technology, more stable and durable. |

|

PLC and Touch Screen Brand: Siemens Original: Japan Using international brand electrical components to ensure machines running in good condition for longer time. |

|

|

high position tank made of high quality SUS304. |

high quality reflow tank for beverage juice |

Output Product

-

7000-12000 BPH Automatic Bottle Filling Machine / Complete Beverage Production Line

7000-12000 BPH Automatic Bottle Filling Machine / Complete Beverage Production Line

The machine is developed by our company independently, it ...

→ -

Industrial Small Bottled Beverage Filling Line High Capacity 5000-20000 BPH

Industrial Small Bottled Beverage Filling Line High Capacity 5000-20000 BPH

The beverage filling production line is mainly used for was...

→ -

Carbonated Beverage Filling Line 5000 -10000 Can Per/ Hour Drink Canning Machine

Carbonated Beverage Filling Line 5000 -10000 Can Per/ Hour Drink Canning Machine

This machine is used for filling and sealing the cans. Its o...

→ -

Small Bottle Beverage Filling Line Juice Energy Drink Soda Water Filling Machine

Small Bottle Beverage Filling Line Juice Energy Drink Soda Water Filling Machine

3 in 1 beverage filliing Machine is mainly used for the f...

→