Live Chat

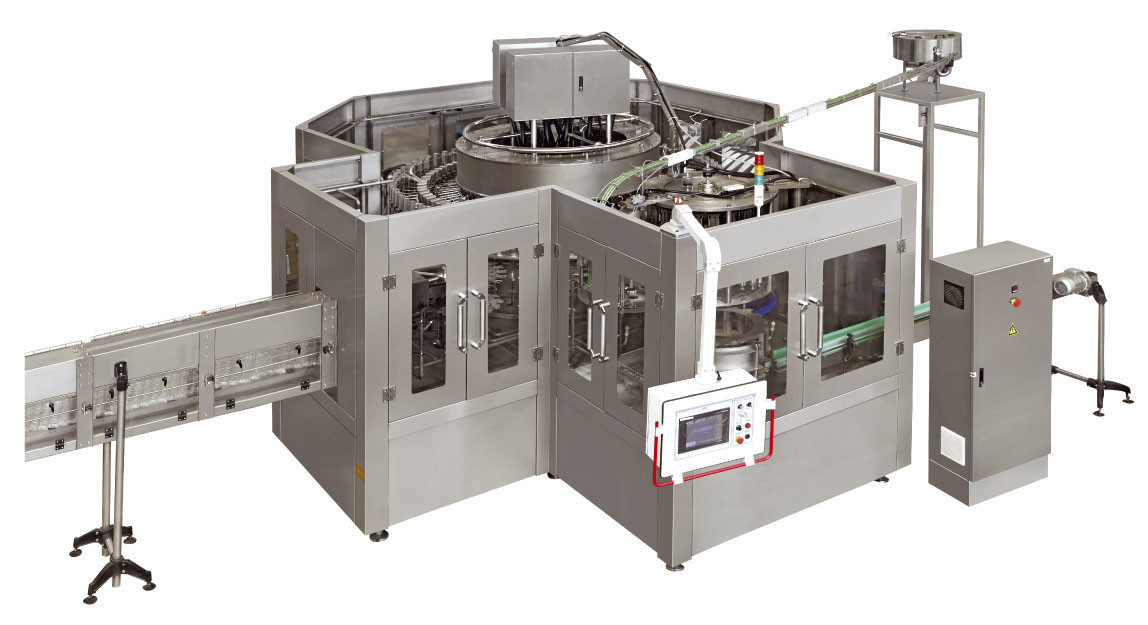

Click the buttonTurnKey Project Automatic Bottle Washing Filling And Capping Machine For PET Bottle

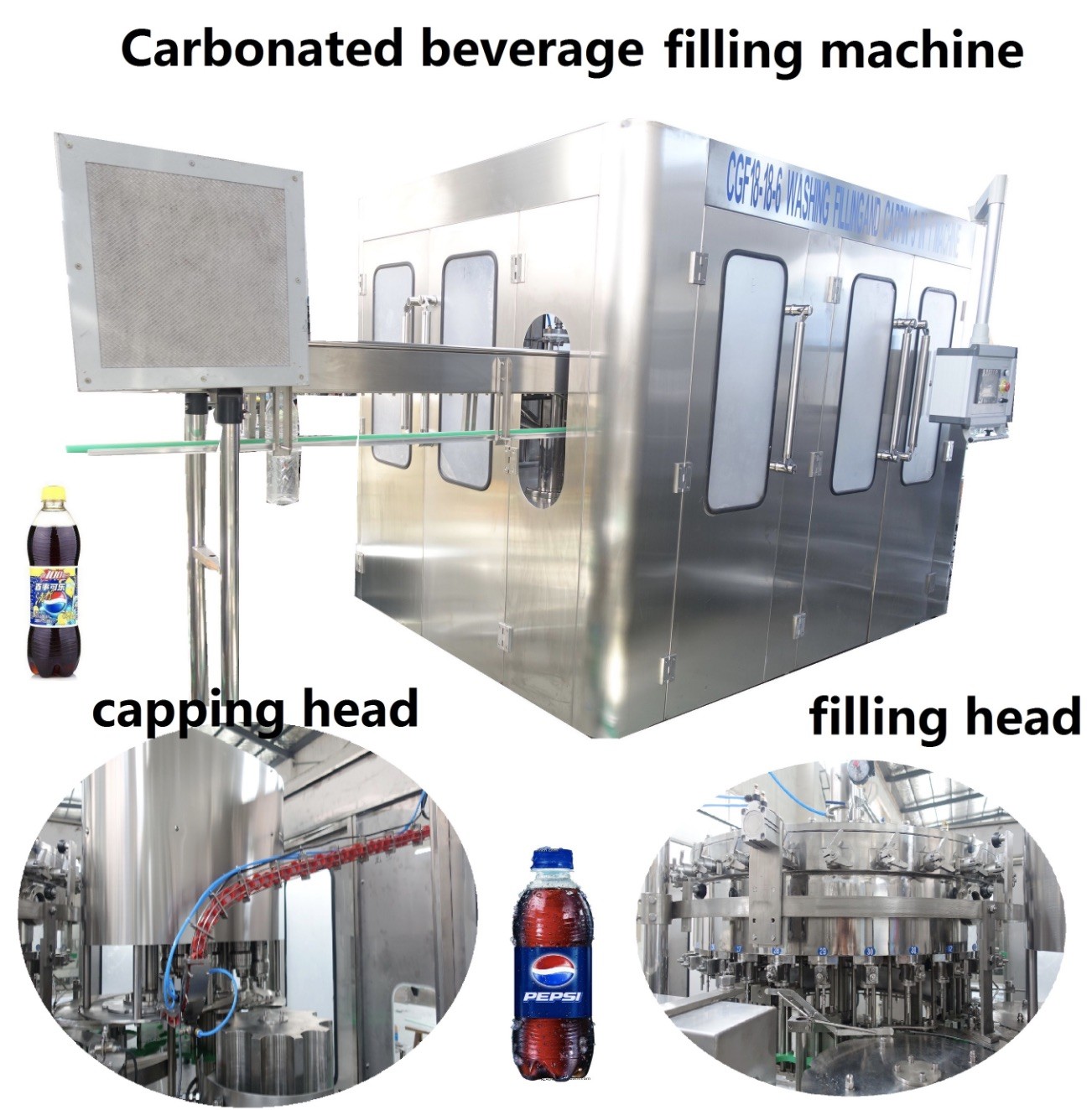

This machine is washing bottle, filling and screw cap for all-in-one PC, used for PET bottle filling carbonated soft drinks (including gas beverage), such as coke, Pepsi, alcohol beverage filling, suitable for PET bottle, glass bottle filling, the equipment is low energy consumption, high efficiency and good stability.

The perfect stainless steel bottle avoids secondary contamination with the bottle screw parts.

Products

-

Bag Filling Machine

-

Beverage Filling Line

-

Biscuit Making Machine

-

Biscuit Production Line

-

Bottle Blowing Machine

-

Carbonated Drink Production Line

-

Cosmetic Filling Machine

-

Drink Production Line

-

Drinking Water Filling Machine

-

Drinking Water Production Line

-

Edible Oil Production Line

-

Fruit Juice Processing Line

-

Juice Filling Machine

-

Plastic Injection Molding Machine

-

Snack Food Production Line

-

UHT Milk Processing Line

-

Water Treatment Systems

-

Vertical Packaging Machine

-

Other Packaging Machine

-

Pillow Type Packaging Machine

-

Pre-made Pouch Packing Machinery

-

Measuring Equipment

-

Cup Filling Machines

-

Conveyor Equipment

-

Auxiliary Equipment

| Product: | PET Bottle Filling Machine | Material: | Stainless Steel 304 |

|---|---|---|---|

| Brand: | Qualipak |

TurnKey Project Automatic Washing Filling Capping Glass Bottle PET Bottle Beverage Filling Line

Production Description

This machine is washing bottle, filling and screw cap for all-in-one PC, used for PET bottle filling carbonated soft drinks (including gas beverage), such as coke, Pepsi, alcohol beverage filling, suitable for PET bottle, glass bottle filling, the equipment is low energy consumption, high efficiency and good stability

Product Advantage:

- The sealing head adopts the constant magnetic torque device to ensure the high quality and no damage.

- This monomer is made of stainless steel. Compact structure, beautiful appearance, reasonable design. It can range from 200ml to 200ml bottle.

- Equipped with high speed filling valve, high filling precision.

- The beverage filling machine adopts advanced PLC control and touch screen. Key electrical components come from internationally renowned brands.

- The perfect stainless steel bottle avoids secondary contamination with the bottle screw parts.

- The machine adopts the advanced bottleneck clamping system to meet the requirement of bottle height. Therefore, for different bottle shapes, only need to change a few parts, such as the guide plate and the rotary wheel, it is more convinient.

Specifications:

| Model: | DCGF12-12-5 | DCGF16-12-6 | DCGF18-18-6 | DCGF24-24-8 |

| Capacity:500ml | 2000-2900bph | 2900-4000bph | 4000-5000bph | 5000-9000 |

| Bottle shape: | round or square | |||

| PET bottle: (mm) | (Bottle Diameter): φ50-φ110mm (Height): 150-310mm (Volume: 250ml -2000ml) | |||

| Cap: | Plastic screw cap | |||

| Filling precision: | ≤±5mm | |||

| Power(KW) | 3.0 | 4.0 | 4.2 | 5.2 |

| Filling pressure: (MPa) | 0.15-0.35 | 0.15-0.35 | 0.15-0.35 | 0.15-0.35 |

| Rinsing pressure: (MPa) | 0.2-0.25 | 0.2-0.25 | 0.2-0.25 | 0.2-0.25 |

| Overall size:(mm) | 1900*1500*2350 | 2250*1650*2350 | 2600*1965*2350 | 2990*2200*2250 |

| Weight: (KG) | 2900 | 3500 | 4000 | 4500 |

| Model: | DCGF32-32-10 | DCGF40-40-15 | DCGF50-50-15 | DCGF60-60-15 |

| Capacity:500ml | 9000-10000 | 10000-15000 | 16000-20000bph | 20000-24000bph |

| Bottle shape: | round or square | |||

| PET bottle: (mm) | (Bottle Diameter): φ50-φ110mm (Height): 150-310mm (Volume: 250ml -2000ml) | |||

| Cap: | Plastic screw cap | |||

| Filling precision: | ≤±5mm | |||

| Power(KW) | 6.2 | 7.5 | 8.5 | 9.8 |

| Filling pressure: (MPa) | 0.15-0.35 | 0.15-0.35 | 0.15-0.35 | 0.15-0.35 |

| Rinsing pressure: (MPa) | 0.2-0.25 | 0.2-0.25 | 0.2-0.25 | 0.2-0.25 |

| Overall size:(mm) | 3890*2200*2250 | 4000*2250*2250 | 5500*3500*2250 | 6500*5500*2250 |

| Weight: (KG) | 6000 | 7000 | 8200 | 9500 |

Product Show:

TurnKey Project

We Supply Turn-key project for our custoemrs, and we also provide the Complete Automatic beverage filling line for our customers.

The whole production line contains 5 Major parts:

- Plastic bottle blowing machine.

- Carbonated beverage mixing system and cooling system water cleaning system.

- Transfer system, bottle temperature system, labeling machine, date machine, film packing machine.

- Beverage cleaning filling and filling machine.

The complete line:

- Our production line can produce different bottles, from 200ml to 2000mL liquid bottle, bottle

- Bottle shape can be round or square bottle, plastic bottle and glass bottle. The unique design makes it very easy to replace the different bottle mould.

- We provide training, installation, commissioning and other services for the customer installation engineers to ensure that your engineers can use the production line normally.

- we have more choices for different production lines, including 1200bph, 2800bph, 4000bph, 5500bph, 7000bph. And so on.

- The material is stainless steel 304, food grade clean, safe.

- The factory is highly automated, you can operate on the touch screen to adjust the speed and work of the machine.

-

7000-12000 BPH Automatic Bottle Filling Machine / Complete Beverage Production Line

7000-12000 BPH Automatic Bottle Filling Machine / Complete Beverage Production Line

The machine is developed by our company independently, it ...

→ -

Industrial Small Bottled Beverage Filling Line High Capacity 5000-20000 BPH

Industrial Small Bottled Beverage Filling Line High Capacity 5000-20000 BPH

The beverage filling production line is mainly used for was...

→ -

Carbonated Beverage Filling Line 5000 -10000 Can Per/ Hour Drink Canning Machine

Carbonated Beverage Filling Line 5000 -10000 Can Per/ Hour Drink Canning Machine

This machine is used for filling and sealing the cans. Its o...

→ -

Small Bottle Beverage Filling Line Juice Energy Drink Soda Water Filling Machine

Small Bottle Beverage Filling Line Juice Energy Drink Soda Water Filling Machine

3 in 1 beverage filliing Machine is mainly used for the f...

→