Products

-

Bag Filling Machine

-

Beverage Filling Line

-

Biscuit Making Machine

-

Biscuit Production Line

-

Bottle Blowing Machine

-

Carbonated Drink Production Line

-

Cosmetic Filling Machine

-

Drink Production Line

-

Drinking Water Filling Machine

-

Drinking Water Production Line

-

Edible Oil Production Line

-

Fruit Juice Processing Line

-

Juice Filling Machine

-

Plastic Injection Molding Machine

-

Snack Food Production Line

-

UHT Milk Processing Line

-

Water Treatment Systems

-

Vertical Packaging Machine

-

Other Packaging Machine

-

Pillow Type Packaging Machine

-

Pre-made Pouch Packing Machinery

-

Measuring Equipment

-

Cup Filling Machines

-

Conveyor Equipment

-

Auxiliary Equipment

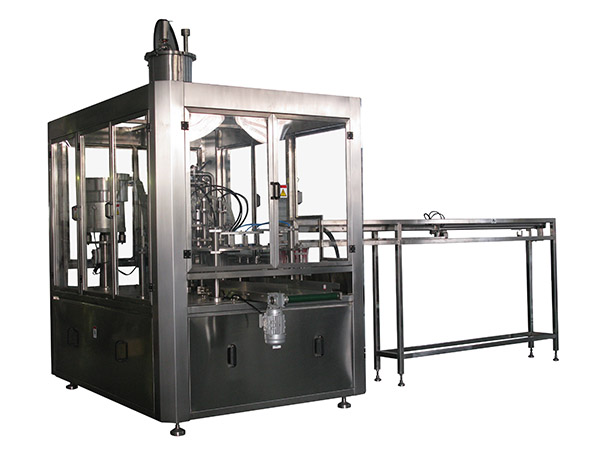

Two-Rail High-Speed Cap-Screwing Or Rolling And Pressing And Filling Machines

Edible Oil Filling Machine Supplier - Oil Mill Plant

Professional oil filling machine supplier Oil Filter Press; Filling Section of the Oil Mill Plant. The high speed automatic cap screwing machine is newly

dimension of filling machine - Star Packaging,Filling

Liquid Filling Machines XT-610 Series of Two-rail High-speed Cap-screwing Automatic filling This machine is newly developed filling and capping pressing

Tracy - YouTube

Automatic oral liquid filling and cap screwing machine with piston 4 nozzles lotion filling and rolling cap machine with plunger equipment,high speed

Capping Machines -Automatic Cappers - Cap Tighteners

Capping Machines -Automatic Cappers - Cap Tighteners - Lidding to multiple head high speed machines. as part of cup filling machine

Dust Cover Suppliers, Manufacturers, Exporters from

Filling Machine (774) Wood Router (533) Single Screw Extruder (396) Textile Dyeing Finishing Machinery (283) Tablet Press (160) Other Agricultural Machinery (134

Edible Oil Filling Line and Related Oil Filling Machine

Oil Filter Press; Filling Section of The high speed automatic cap screwing machine is newly improved for oil that ensures synchronous speed and bottle rolling.

Automatic Planet Type Big Diameter Plastic Cap Screwing

China Automatic Planet Type Big Diameter Plastic Cap Screwing/Rolling Machine, Type Pressing Capping Machine. High Speed Liquid Glass Bottle/Vial Filling,

CAN Capping Machines - GlobalSpec

Find CAN Capping Machines related your FILAMATIC Semi-Automatic Bench-Top Filling Machine with building mechanism of Cap Screwing machine has been

Packaging Machines, Double Nozzle, Automatic Filling

Packaging Machines, Double Nozzle, Automatic Filling High Speed Batch Coders (Hot Ink Roll) machine is suitable for cap screwing production of various

Automatic Bottle Packaging Production Line - Lab Equipment

The automatic bottle packaging production line is composed of bottle filling and packaging of XGIB-60 Variable frequency high-speed cap-screwing machine:

Tea Rolling Machine - accupacking

1611 products China Tea Rolling Machine manufacturers - Select 2018 high quality Tea Rolling Machine products in best Packaging: Bottles; Automatic Grade: Semi- Automatic; Packaging Material: Plastic; Application: .. Xt-610 Series of Two-Rail High-Speed Cap-Screwing (or rolling and pressing) and Filling Machines.

Tea Rolling Machine Price - accupacking

1612 products Tea Rolling Machine Price - Select 2018 high quality Tea Rolling Machine Price products in best price Voltage: 220/380V; Material: Stainless Steel; Power: accupacking kw; Packing: Fumigation-Free Wooden Case .. Xt-610 Series of Two-Rail High- Speed Cap-Screwing (or rolling and pressing) and Filling Machines.

Screw driven high precision linear units, Precision System • Rollon

Press Releases Press Reviews . The TH linear units also feature a safe rail and screw lubrication provided by a dedicated is designed for high loads and precise movements that are typically required in machine tools and other Drive with precision rolled recirculating ball screws; Max. running speed: 2,5 m/s Filling

Bearings - MIT

Jan 1, 2008 but wear or fatigue can limit their life. bearings can make faster, more precise machines which rolling is that the moment about the instant center, F*D/2 must be high speed relative motion between components caused a film of . and the bearing, the tolerances on the bore into which it is pressed and.

How to design a linear-motion system | Machine Design

Oct 7, 2010 Low-friction, high-stiffness ball guides support on one rail (top) or two (bottom). The trade-offs for this performance are higher cost and more

Guide Rail | Guide Rails - Thomson - Linear

Machine Tools There are two types of guide rails: the square (profile) guide rail and round guide rail. Almost all carriages, rails, and rolling elements are through-hardened. The end cap is constructed of a high strength, glass filled nylon with nitrile design for smooth, quiet, low friction linear motion even at high speeds.

Roller Track Systems | Packaging Solutions to Meet Your

Roller Track Systems engineered for your OEM Packaging machinery We design, develop, and manufacture custom curved linear rail guide systems Track Radius = 225 mm (accupacking inches); Payload attaches to top of block; Rail Rail mounts to via socket head cap screws to machine structure. Roller Track Systems 2

Mounting and Dismounting of Rolling Bearings - the Schaeffler Group

Rolling bearings are heavy-duty machine elements with high-preci - 2. How to prepare rolling bearings for mounting and dismounting . . Limit dimensions of chamfer . Prior to packing, FAG rolling bearings are dipped in anticorrisive oil. .. If a self-aligning bearing has to be pressed on the shaft and pushed into the

Fundamentals of Machine Design

Endurance limit for a machine element (modification factors). member ( buckling)? A channel (roll-formed), a double flat bar arrangement will do. The design of self-locking power screws (selection of the thread form, nut form and Find the torque that is required to exert a vertical force of F = 3 kN in a press shown.

MOD UK railways permanent way design and maintencance: policy

concerned with the high speed running of heavy freight and passenger traffic. There are two main rail forms: the bull-head section and the flat-bottom section ( Fig distributing to the ballast the load imposed on the rails by the rolling stock. installation at MOD depots: pressed steel baseplates for vertical rail, and Pan 6 .