Live Chat

Click the buttonStable Hot Juice Filling Machine 2000 BPH – 20000 BPH Capacity For Pet Bottle

Flushing and filling sealing machine is mainly used for pulp hot filling juice. Four bottle washing functions, grouting and juice fillign cover to form a body of the machine. The whole process is automatic. Because each part of the machine is photoelectric detection, easy to operate, the automation degree is high, is the beverage manufacturer’s ideal equipment.

Products

-

Bag Filling Machine

-

Beverage Filling Line

-

Biscuit Making Machine

-

Biscuit Production Line

-

Bottle Blowing Machine

-

Carbonated Drink Production Line

-

Cosmetic Filling Machine

-

Drink Production Line

-

Drinking Water Filling Machine

-

Drinking Water Production Line

-

Edible Oil Production Line

-

Fruit Juice Processing Line

-

Juice Filling Machine

-

Plastic Injection Molding Machine

-

Snack Food Production Line

-

UHT Milk Processing Line

-

Water Treatment Systems

-

Vertical Packaging Machine

-

Other Packaging Machine

-

Pillow Type Packaging Machine

-

Pre-made Pouch Packing Machinery

-

Measuring Equipment

-

Cup Filling Machines

-

Conveyor Equipment

-

Auxiliary Equipment

| Type: | Fruit Juice Filling Machine | Application: | Beverage, Food, Carbonated Beverage |

|---|---|---|---|

| Automatic Grade: | Automatic | Driven Type: | Electric |

| Dimension(L*W*H): | 4500*2000*2500mm | After-sales Service Provided: | Engineers Available To Service Machinery Overseas |

| Material: | SUS 304 | Bottle: | PET Bottle,glass Bottle,jar,pot, Can |

| Bottle Size: | 0.5-2L | Filling Precision: | ≤±2mm |

| Bottle Type: | Round Bottle, Case Bottle ,square Bottle, Flat Bottle |

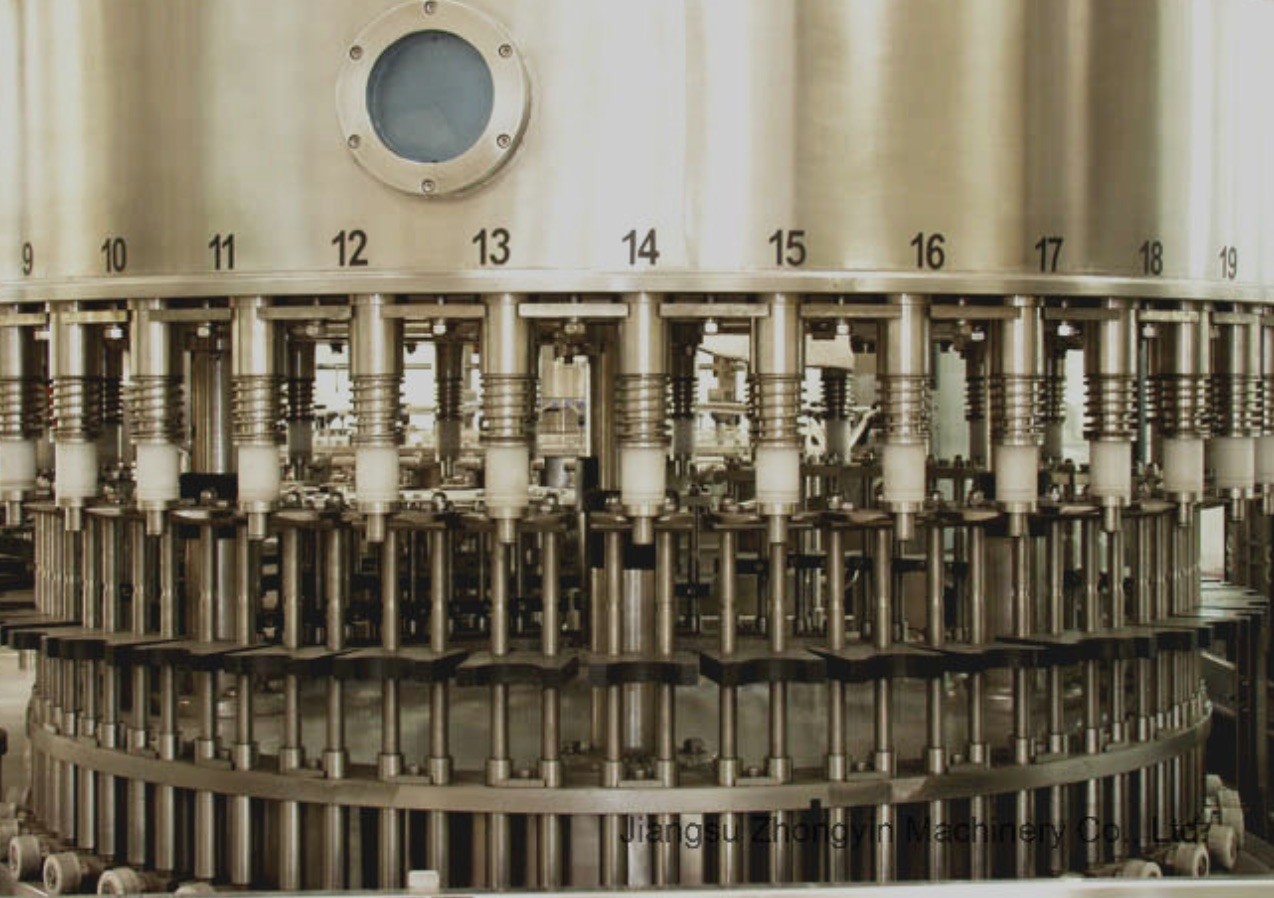

Stable 2000BPH – 20000BPH Capacity Hot Juice Filling Machine / Juice Filling Equipment For Pet Bottle

Advanced Siemens program controller (PLC) control

High Speed with max stable Capacity 38000BPH

NoTouch of Bottle neck

Suitable for Different bottle Shap e

Flushing and filling sealing machine is mainly used for pulp hot filling juice. Four bottle washing functions, grouting and juice fillign cover to form a body of the machine. The whole process is automatic. Because each part of the machine is photoelectric detection, easy to operate, the automation degree is high, is the beverage manufacturer's ideal equipment.

Product Freatures

- Washing and filling sealing machine is mainly used for hot juice filling . Four bottle washing functions, grouting and juice fillign cover to form a body of the machine. The whole process is fully automatic.

- The juice filling machine screw down when the bottle is out of the bottle.

- Advanced Siemens program controller (PLC) control the machine to run automatically, adopt inverter speed control in the bottle feeding chain, coordinated with the host inverter, make mobile bottle forward work smoothly and reliably.

- Filling machine is a high speed and large flow valve filling valve, filling speed is fast, filling is accurate, no liquid loss.

- The juice filling machine is the technology that USES the direct connection of the air supply and the bottle wheel, cancels the screw and the conveyor chain, so that the change of the bottle shape becomes easier.

- The juice filling machine adopts advanced PLC automatic control technology, the core electrical components are from famous companies such as mitsubishi of Japan, schneider of France and omron.

- The machine handle is free and easy to rotate, and can adjust the machine to fill all kinds of bottles. The new type of micro-pressure filling operation is adopted, and the filling operation is fast and stable.

- Constant temperature system of juice filling machine, temperature control and automatic circumfluence.

- The juice filling machine is specially designed for stainless steel bottle washing machine, which is strong and durable, and does not touch the thread position of the bottle mouth to avoid secondary pollution.

- The bottle transmission of juice filling machine adopts the bottleneck technology of the card, the bottle shape conversion does not need to adjust the equipment level, it is enough to replace the bent plate, wheel and nylon parts.

|

Number of washing positions |

18 |

|

Numbner of pulp filling positions |

12 |

|

Number of filling positions |

18 |

|

Number of capping positions |

6 |

|

Capacity (based on 500ml) |

5000-6000bottles/hour |

|

Suitable bottle height (mm) |

160-340 |

|

Suitable bottle diameter (mm) |

¢50-¢90 |

|

Power of main motor (KW) |

4.8kw |

|

Water pressure (Mpa) |

0.25-0.3Mpa |

|

Shape dimension |

4550MM*2000MM*2500MM |

|

Weight |

6500kg |

|

Filling temperature |

Hot filling |

|

Suitable bottle |

Glass bottle with pulp cap / Pet bottle |

Product Show

Service

- We offer a one-year warranty service for 12 months guarantee and lifelong technical support.

- 24 hours for engineer response

- Well -trained and experienced staff are responding to all your queries in English Chinese.

- When you finish the preparation conditions, our fast and professional after-sales service service engineer team will go to your factory to install the machine, to give you the operation manual, training staff, until they can operate the machine with you well.

- When you finish the preparation conditions, our fast and professional after-sales service service engineer team will go to your factory, give you the operation manual, training staff, until they can operate the machine with you well.

-

300 ML -1000 ML Hot Fill Bottling Equipment , Plastic Bottle Orange Juice Production Line

300 ML -1000 ML Hot Fill Bottling Equipment , Plastic Bottle Orange Juice Production Line

This machine is mainly used for juice filling. The machine h...

→ -

Mango Juice Filling Machine High Capacity 300 ml-2000 ml PET Bottles / Glass Bottle

Mango Juice Filling Machine High Capacity 300 ml-2000 ml PET Bottles / Glass Bottle

This juce filling machine is a kind of efficient automatic j...

→ -

PET Bottle Fruit Juice Production Line , Automatic Fruit Juice Packaging Machine

PET Bottle Fruit Juice Production Line , Automatic Fruit Juice Packaging Machine

The fruit juice filling machine design is reasonable, the ap...

→ -

Stainless Steel 3 In 1 Water Filling Machine , Small Scale Juice Bottling Equipment

Stainless Steel 3 In 1 Water Filling Machine , Small Scale Juice Bottling Equipment

Cleaning (bottle), filling and sealing will be completed by ...

→