Live Chat

Click the button100 kg / H – 250KG / H Biscuit / Cookie Production Line For Snack Food IOS9001 Certificated

Different shapes of snacks can be produced such as Round, triangle, square, stars, flower, etc

Biscuit food making machine can produce all kinds of inflating foodstuffs, rice bread, core snacks, crackers, gruel nutrient-flour, and baby food and so on.

Biscuit food making machine screws are made by alloy steel and special craft, the screw life is longer, uses building block system structure, may combine willfully

Products

-

Bag Filling Machine

-

Beverage Filling Line

-

Biscuit Making Machine

-

Biscuit Production Line

-

Bottle Blowing Machine

-

Carbonated Drink Production Line

-

Cosmetic Filling Machine

-

Drink Production Line

-

Drinking Water Filling Machine

-

Drinking Water Production Line

-

Edible Oil Production Line

-

Fruit Juice Processing Line

-

Juice Filling Machine

-

Plastic Injection Molding Machine

-

Snack Food Production Line

-

UHT Milk Processing Line

-

Water Treatment Systems

-

Vertical Packaging Machine

-

Other Packaging Machine

-

Pillow Type Packaging Machine

-

Pre-made Pouch Packing Machinery

-

Measuring Equipment

-

Cup Filling Machines

-

Conveyor Equipment

-

Auxiliary Equipment

| Application: | Biscuit,cookie, | Power(W): | 48KW |

|---|---|---|---|

| Weight: | 2000KG | Dimension(L*W*H): | 2700*900*2000MM |

| After-sales Service Provided: | Engineers Will Be Delivered To Clinets Factory | Product Name: | Biscuit Making Machine |

| Materail: | Food Grade Stainless Steel | Optput: | 100-250kg/h |

| Snacks Style: | Core Filling And Normal Style | Automatic Grade: | Fully Automatic And Semi-automatic |

| Color: | Silver | Input Material: | Corn,Rice,Wheat,Rye,oat, |

| Manufacturer: | Biscuit Making Machine | Product Type: | Biscuit Food Packaging Machine |

100 kg / H – 250KG / H Biscuit / Cookie Production Line For Snack Food IOS9001 Certificated

Specifications

We offer CE,IOS9001 Certificated Turnkey Biscuit Production line for snack food,the primary benefits of biscuit production line as bellow:

1.Flexible design for wide range snack food.

2.High quality with imported spares

3.Overseas service with installation and after-sale service

4.CE.ISO9001 certificated

5.1 Years warranty for global market.

Product Features

-

Biscuit Production line for Snack food

- With flexiable desin,it is able to produce extruded snacks,the input material could be corn,rice,wheat,rye,oat,and other grains.the snack isy produced with livel shape with crispy taste.

- Different shapes of snacks can be produced such as Round, triangle, square, stars, flower, etc

- Biscuit food making machine can produce all kinds of inflating foodstuffs, rice bread, core snacks, crackers, gruel nutrient-flour, and baby food and so on.

- Biscuit food making machine screws are made by alloy steel and special craft, the screw life is longer, uses building block system structure, may combine willfully

- The forced lubrication system, by guaranteed equipment transmission longer life.

- Visible auto-temperature controlling system, make the temperature-controlling to be more direct-viewing, parameter to be more precise.

- totally customized according to customers need;

-

Voltage

- 3 phases: 380V/50Hz, Single phase: 220V/50Hz, for worldwide clients, we offer customzied voltage according to needs.

-

Capacity

- our device could reach more than 500kg/hour cpacity ,which includes 100 to 150kg/h( with TES 65 Extruder), 250-300kg/h(with TES70 Extruder),300-500kg/h(with TES 85 Extruder),

Technical parameters

| Device Parameter | MT-653 Production Line | MT-70 Production Line | MT-500 Production Line |

| Installed capacity | 150KW | 220KW | 280KW |

| Consumption | 120KW/H | 150KW/H | 190KW/H |

| Output | 130-15 KG/H | 240-260KG/H | 500-600KG/H |

| Dimension | 18000*2000*4000MM | 22000*2000*4000MM | 26000*2000*4000MM |

Flow chart

a. Mixing system

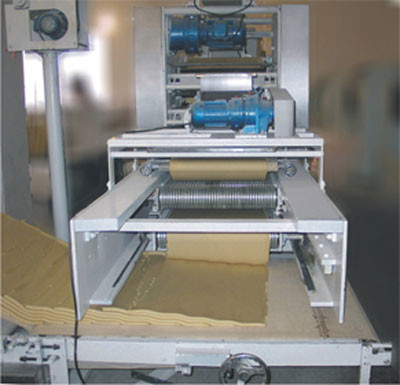

b. Extrusion system

c. Baking system (Frying System)

d. Flavoring system

e. Packing system

3. The processing of machine includes :

1. materia feeding

2. material extruding

3. major filling

4. formation

5. slicing

6. cooking oil spraying

the complete process is complete with machine automaticlly,which is efficient and reliable.

1.Tech assistance on-line support supplied

2.Technological document assistance provided

3.On-site instruction assistance supplied

4. Spare items replacing and maintenance service supplied

-

Commercial Cracker Production Line , Moulded Biscuit Processing Line For Food Industry

Commercial Cracker Production Line , Moulded Biscuit Processing Line For Food Industry

1.) Free Consultation service crossing whole process; 2.)...

→ -

Hand / Soft Biscuit Production Line Automatic Animal Shaped Multifunction

Hand / Soft Biscuit Production Line Automatic Animal Shaped Multifunction

Biscuit machine production line is offered for a variety of ...

→ -

Small Capacity Automatic Industrial Biscuit Making Machine For Wide Range Shapes

Small Capacity Automatic Industrial Biscuit Making Machine For Wide Range Shapes

With Roller extrusion dough ,Automatic Biscuit Processing Li...

→ -

Wafer Biscuit Production Line Semi Automatic / Automatic Coin Chocolate Pure Chocolate

Wafer Biscuit Production Line Semi Automatic / Automatic Coin Chocolate Pure Chocolate

We are reliable and professional chocolate Biscuit productio...

→