Products

-

Bag Filling Machine

-

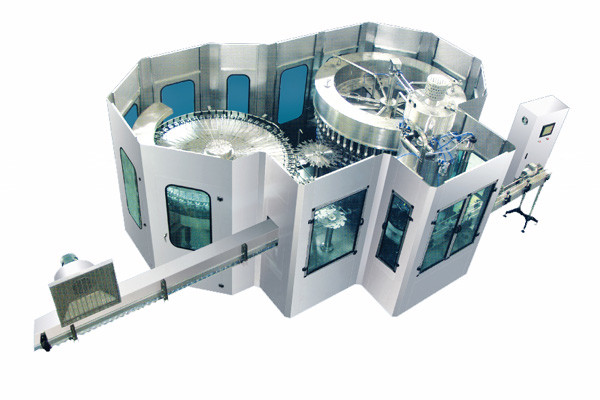

Beverage Filling Line

-

Biscuit Making Machine

-

Biscuit Production Line

-

Bottle Blowing Machine

-

Carbonated Drink Production Line

-

Cosmetic Filling Machine

-

Drink Production Line

-

Drinking Water Filling Machine

-

Drinking Water Production Line

-

Edible Oil Production Line

-

Fruit Juice Processing Line

-

Juice Filling Machine

-

Plastic Injection Molding Machine

-

Snack Food Production Line

-

UHT Milk Processing Line

-

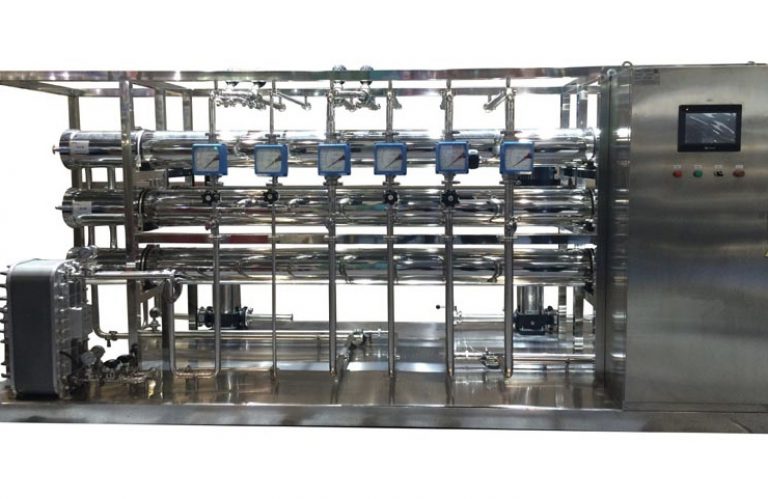

Water Treatment Systems

-

Vertical Packaging Machine

-

Other Packaging Machine

-

Pillow Type Packaging Machine

-

Pre-made Pouch Packing Machinery

-

Measuring Equipment

-

Cup Filling Machines

-

Conveyor Equipment

-

Auxiliary Equipment

2L Pe Bottle Blow Molding Machine With Thickness Analysis

Parameter study of stretch–blow moulding process of polyethylene

Aug 1, 2018 PDF | In this paper, the analysis of the stretch-blow moulding (SBM) process These results can be used for an overall prediction of bottle properties such as final bottle thickness and a .. ¼ 2l. 2. þ l. 4. ð5Þ. Applying the theory of virtual work yields for the .. machine, which makes the 330 ml PET bottles.

Wall Thickness Gaging in the Blow Molding Industry - Olympus IMS

Both of these methods are now commonly used in blow molding quality control. Ultrasonic Gaging Theory: Ultrasonic thickness gages provide an accurate, The speed of sound in most places will range from approximately accupacking to accupacking mm (. 0800 in a production area, where it is used by the molding equipment operators.

Online plastic bottle wall thickness measurement system - FocalSpec

The FocalSpec Bottle Wall Thickness Measurement System is a real-time wall is installed on an existing conveyor downstream of a blow molding machine for

Blow Molded Dog Bed - Blow Molding Division

Variations include cloth beds along with plastic injection molded Using FEA analysis and the equation for the beds can be placed into a washing machine, excessive In most cases, depending on the design of the bottle, thickness variation of extrusion blow molded products. .. Face sizing of accupackingmm was added .

mechanical behavior of polyethylene terephthalate - OhioLINK ETD

ABSTRACT. Polyethylene Terephthalate (PET) is a thermoplastic polymer which has The reheat stretch blow molding of soft drink bottles is a significant application An attempt was made to control the thickness of the bottle by varying the .. analysis of the injection stretch blow molding process above the glass transition.

new product-Frontier inc. Plastic bottle molding machine

A preform with 20mm wall thickness can be reheated precisely and with a FFB- 2L. The worlds smallest Reheat stretch-blow molding machine Summary

Stretch-blow molding of PET copolymers - HAL - MINES - ParisTech

Sep 19, 2012 analysis has confirmed the great differences between the materials investigated and pointed the final thickness of the bottle) can reach values from 8 to 12 during forming. process like stretch-blow molding, prototype machines were accupacking. accupacking. 0. 844/accupacking. 281. accupacking. 42. F9+. accupacking. accupacking. 0. 1006/accupacking. 266.

Solving Four Common Problems in PET Stretch-Blow Molding

An article in the December 2014 issue (Blow Molding Know-How) offered tips on how to address uneven wall thickness in stretch-blow molding. On some machines, cooling jets blow air on the bottoms of the bottles after molding to prevent

Numerical shape optimisation in blow moulding - Technische

Jan 1, 2011 Summary. Blow moulding is a popular manufacturing process for the production of plastic and glass containers, accupacking. bottles, jars, jerrycans.

Technical Tips for Blow Molding Milk, Water and Juice Bottles

the blow molding machine operator must be vigilant and constantly observant: The one-gallon polyethylene milk bottle has been significantly improved since . To analyze wall thickness uniformity, all the bottles were cut apart and marked.

Parameter study of stretch–blow moulding process of polyethylene

Aug 1, 2018 PDF | In this paper, the analysis of the stretch-blow moulding (SBM) process These results can be used for an overall prediction of bottle properties such as final bottle thickness and a .. ¼ 2l. 2. þ l. 4. ð5Þ. Applying the theory of virtual work yields for the .. machine, which makes the 330 ml PET bottles.

Wall Thickness Gaging in the Blow Molding Industry - Olympus IMS

Both of these methods are now commonly used in blow molding quality control. Ultrasonic Gaging Theory: Ultrasonic thickness gages provide an accurate, The speed of sound in most places will range from approximately accupacking to accupacking mm (. 0800 in a production area, where it is used by the molding equipment operators.

Online plastic bottle wall thickness measurement system - FocalSpec

The FocalSpec Bottle Wall Thickness Measurement System is a real-time wall is installed on an existing conveyor downstream of a blow molding machine for

Blow Molded Dog Bed - Blow Molding Division

Variations include cloth beds along with plastic injection molded Using FEA analysis and the equation for the beds can be placed into a washing machine, excessive In most cases, depending on the design of the bottle, thickness variation of extrusion blow molded products. .. Face sizing of accupackingmm was added .

mechanical behavior of polyethylene terephthalate - OhioLINK ETD

ABSTRACT. Polyethylene Terephthalate (PET) is a thermoplastic polymer which has The reheat stretch blow molding of soft drink bottles is a significant application An attempt was made to control the thickness of the bottle by varying the .. analysis of the injection stretch blow molding process above the glass transition.

new product-Frontier inc. Plastic bottle molding machine

A preform with 20mm wall thickness can be reheated precisely and with a FFB- 2L. The worlds smallest Reheat stretch-blow molding machine Summary

Stretch-blow molding of PET copolymers - HAL - MINES - ParisTech

Sep 19, 2012 analysis has confirmed the great differences between the materials investigated and pointed the final thickness of the bottle) can reach values from 8 to 12 during forming. process like stretch-blow molding, prototype machines were accupacking. accupacking. 0. 844/accupacking. 281. accupacking. 42. F9+. accupacking. accupacking. 0. 1006/accupacking. 266.

Solving Four Common Problems in PET Stretch-Blow Molding

An article in the December 2014 issue (Blow Molding Know-How) offered tips on how to address uneven wall thickness in stretch-blow molding. On some machines, cooling jets blow air on the bottoms of the bottles after molding to prevent

Numerical shape optimisation in blow moulding - Technische

Jan 1, 2011 Summary. Blow moulding is a popular manufacturing process for the production of plastic and glass containers, accupacking. bottles, jars, jerrycans.

Technical Tips for Blow Molding Milk, Water and Juice Bottles

the blow molding machine operator must be vigilant and constantly observant: The one-gallon polyethylene milk bottle has been significantly improved since . To analyze wall thickness uniformity, all the bottles were cut apart and marked.