Live Chat

Click the button3000 – 2000 BPH Drinking Water Filling Machine 3 In 1 Washing Filling And Capping Machine

Drinking water filling machine speciallized in filling small bottle of purified water, mineral water and other non carbonated beverages. fully automatic with PLC control system,eay to operate , efficient and stable working ,reduct the running cost of your business.

Products

-

Bag Filling Machine

-

Beverage Filling Line

-

Biscuit Making Machine

-

Biscuit Production Line

-

Bottle Blowing Machine

-

Carbonated Drink Production Line

-

Cosmetic Filling Machine

-

Drink Production Line

-

Drinking Water Filling Machine

-

Drinking Water Production Line

-

Edible Oil Production Line

-

Fruit Juice Processing Line

-

Juice Filling Machine

-

Plastic Injection Molding Machine

-

Snack Food Production Line

-

UHT Milk Processing Line

-

Water Treatment Systems

-

Vertical Packaging Machine

-

Other Packaging Machine

-

Pillow Type Packaging Machine

-

Pre-made Pouch Packing Machinery

-

Measuring Equipment

-

Cup Filling Machines

-

Conveyor Equipment

-

Auxiliary Equipment

| Type: | Automatic Washing Filling Capping Machine | Application: | Beverage, Chemical, Medical |

|---|---|---|---|

| Packaging Type: | Barrel, Bottles, Cans | Driven Type: | Electric |

| Certification: | CE ISO | After-sales Service Provided: | Engineers Available To Service Machinery Overseas |

| Warranty: | 1year | Capacity: | 300-20000BPH |

3000-2000BPH Automatic 3-in-1 Drinking Water Filling machine For Small PET Bottle CE,ISO

Feature:

1. Capacity: 1000bph-20000bph

2. Full Automatic

3. Advanced Technology

4.The water filling machine is used to produce carbonated beverage, such as cola,beer

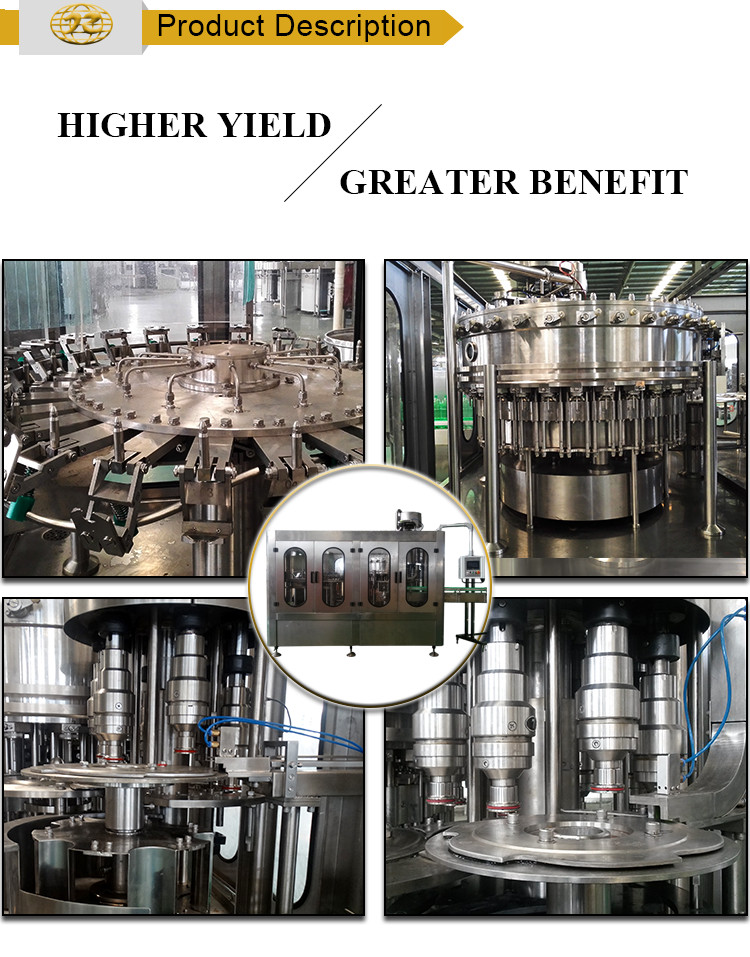

Product Description

Drinking water filling machine speciallized in filling small bottle of purified water, mineral water and other non carbonated beverages. fully automatic with PLC control system,eay to operate , efficient and stable working ,reduct the running cost of your business.

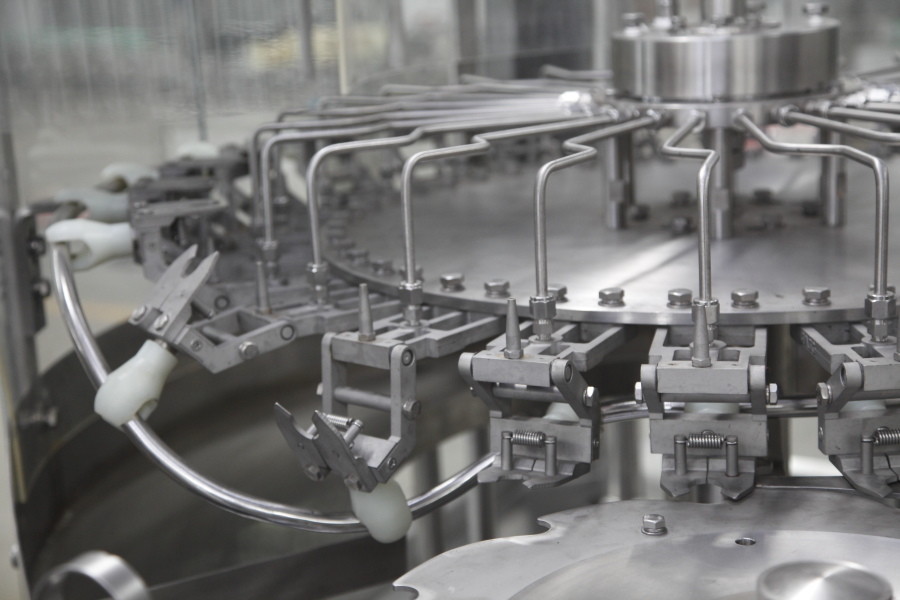

Proudct Features

- The mitsubishi touch screen is easy to operate.

- Intelligent security detection system, equipped with overload protection device to ensure the safety of operators and machines.

- Quality assurance, main electronic components (touch screen, PLC, frequency converter) are imported products.

- PLC control system operation, touch screen operation.

- The unique design of the flip bottle is made of SUS304 stainless steel and durable.

- High – end pressure filling nozzle provides fast, efficient and accurate distribution with minimal leakage.

- The main electric components of famous companies such as Japan, mitsubishi, France schneider and omron are adopted by advanced PLC automatic control technology.

- Through CE certification, according to industry standard and all safety standard design of mechanical and cable layout.

Product Show:

Secifications

All main components makers are world-known manufacturers.

| Model | MT32-32-10 | MT40-40-12 | MT50-50-15 | MT 60-60-15 | MT72-72-18 | MT 80-80-18 |

| Production Capacity(500ml b/h) | 12000-15000 | 18000-22000 | 22000-25000 | 25000-28000 | 28000-30000 | 35000-36000 |

| Washing heads | 32 | 40 | 50 | 60 | 72 | 80 |

| Filling heads | 32 | 40 | 50 | 60 | 72 | 80 |

| Capping heads | 10 | 12 | 15 | 15 | 18 | 18 |

| Suitable Bottles | PET Round or Square | |||||

| Bottle Diameter(mm) | 50-90 | |||||

| Bottle height(mm) | 150-340 | |||||

| Compressed Air Pressure(Mpa) | 0.3-0.7 | |||||

| Washing Medium | Aseptic Water | |||||

| Washing water pressure(Mpa) | 0.25 | |||||

| Power(Kw) | 6 | 7.5 | 9.5 | 11.2 | 15 | 18 |

| Overall sizes(cm) | 380×280×290 | 460×280×290 | 545×330×290 | 620×450×230 | 650×480×285 | 650×500×285 |

| Weight(kg) | 5600 | 8500 | 9800 | 12800 | 15000 | 18000 |

Output Product

Our Service

- We provide door to door service for installation, commissioning, it makes sure that the machine could works perfect after you receiving equipment , at the same time our engineer will give training to your engineer , these services are free of charge.

- We are committed to provide 24 months maintenance period, as long as it is our design, manufacturing and the problem of the material quality, we will solve the problem for you, and we provide parts for you , of course, these service are totatlly free.

- We will adjust the equipment before we ship the equipments, and provide the English instruction manual for machine operation and maintenance along with the equipment, so that you can use the equipment better.

- We will take photos and videos during after delivery, after get your confirmation and payment , we will arrange delivery.

Cooperation process

Inquiry – send quotation – confirm the order – company's proforma invoice and contract.

Method of payment:

A deposit of 30% T/T payment – prepare machines – you send the bottle samples sent our company – we will be the first to work in our company, and debugging equipment with the bottle samples,-we send the equipment and video to you,-your company personnel to come to my company to check the machine – pay the balance payment 70% payment – we arrange delivery – the machine arrive at your factory, our engineers will provie door sevie for installation, commissioning, training

-

300ml-2L PET Bottle Water Filling Machine , Mineral Water Bottling Machine

300ml-2L PET Bottle Water Filling Machine , Mineral Water Bottling Machine

Multifunctional automatic bottle washing, filling and cappin...

→ -

100-5000 BPH Drinking Water Filling Machine Single / Double Nozzle For Pet Bottle

100-5000 BPH Drinking Water Filling Machine Single / Double Nozzle For Pet Bottle

The series of bottled water filling lines is used to produce...

→ -

3 In 1 Automatic Washing Filling Capping Machine For Food / Beverage CE Standard

3 In 1 Automatic Washing Filling Capping Machine For Food / Beverage CE Standard

The machine is mainly used in the beverage filling operation...

→ -

Fully Automatic 3 In 1 Water Filling Machine , Carbonated Beverage Bottling Equipment

Fully Automatic 3 In 1 Water Filling Machine , Carbonated Beverage Bottling Equipment

Fruit juice disinfector or juice storage tank -- high lever ...

→