Live Chat

Click the buttonFully Automatic 3 In 1 Water Filling Machine , Carbonated Beverage Bottling Equipment

Fruit juice disinfector or juice storage tank — high lever tank, filling bottle, filling bottle. Meanwhile, the excess juice flows back to the balance tank through the vacuum system, and the excess juice is sent to the juice sterilizer again.

All the contact parts of the equipment are made of SUS304 material, which can provide a consistent, accurate and accurate filling nozzle. The filling temperature is adjustable, no bottle is not filled.

Products

-

Bag Filling Machine

-

Beverage Filling Line

-

Biscuit Making Machine

-

Biscuit Production Line

-

Bottle Blowing Machine

-

Carbonated Drink Production Line

-

Cosmetic Filling Machine

-

Drink Production Line

-

Drinking Water Filling Machine

-

Drinking Water Production Line

-

Edible Oil Production Line

-

Fruit Juice Processing Line

-

Juice Filling Machine

-

Plastic Injection Molding Machine

-

Snack Food Production Line

-

UHT Milk Processing Line

-

Water Treatment Systems

-

Vertical Packaging Machine

-

Other Packaging Machine

-

Pillow Type Packaging Machine

-

Pre-made Pouch Packing Machinery

-

Measuring Equipment

-

Cup Filling Machines

-

Conveyor Equipment

-

Auxiliary Equipment

| Type: | Filling Machine, Filling Machine | Condition: | New |

|---|---|---|---|

| Application: | Chemical, Food, Machinery & Hardware, Medical | Packaging Type: | Bags, Bottles, Capsule |

| Packaging Material: | Glass, Plastic | Automatic Grade: | Fully Automatic |

| Voltage: | 220V/380V | Power: | 2.5Kw |

| Model Number: | MT-542 | Dimension(L*W*H): | 4700x3320x2700mm |

| Weight: | 5000kg |

3 in 1 Combi Spring Water Spare Parts Beverage Soda Water Filling Machine

Product Description

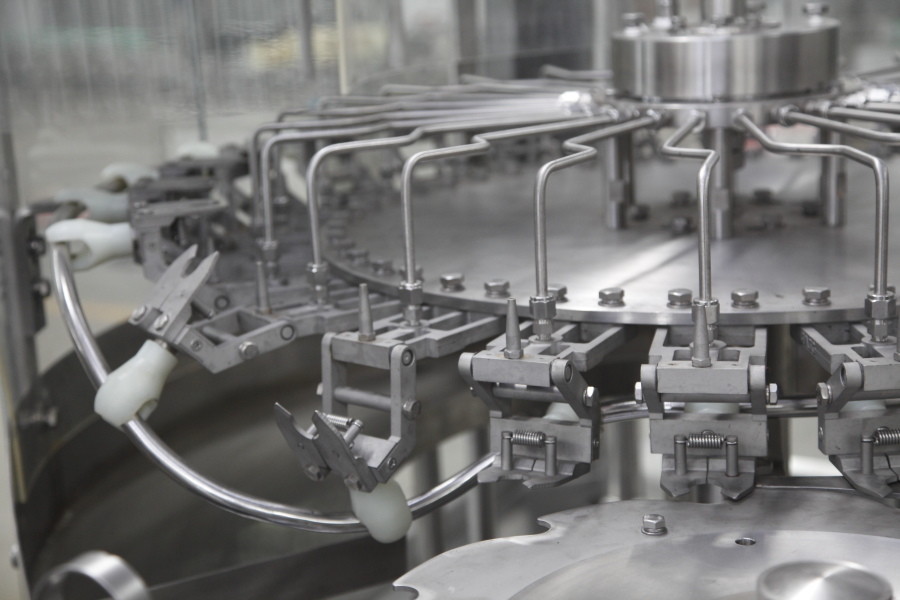

The equipment is equipped with an air conveyor belt, and the main flow of the equipment is as follows:

1 can transport the bottle into the equipment through the conveyor belt.

2. the bottle is fixed to the neck of the bottle to ensure that the bottle will not fall during transportation.

3. this opportunity will pour the juice or water into the PET bottle and can also cover the cover. This machine integrates three functions:

1. Flush the empty bottle,

2. Fill the rinse bottle,

3. Full bottle flushing station:

All the flushing bottles are washed by the food grade stainless steel SUS304. The injection type water collision design is adopted to save water more.

Filling flow chart:

Fruit juice disinfector or juice storage tank — high lever tank, filling bottle, filling bottle. Meanwhile, the excess juice flows back to the balance tank through the vacuum system, and the excess juice is sent to the juice sterilizer again.

All the contact parts of the equipment are made of SUS304 material, which can provide a consistent, accurate and accurate filling nozzle. The filling temperature is adjustable, no bottle is not filled.

|

Technical Parameter

|

|

|

Model

|

MT-657

|

|

Output Capacity

|

12,000Bottle-15,000 per hour on basis of 0.5liter bottle

|

|

Adjustable

|

40pcs

|

|

Rinsing Nozzle Quantity

|

40pcs

|

|

Filling Nozzle Quantity

|

10pcs

|

|

Capping Nozzle Quantity

|

Bottle Diameter Φ50~Φ90mm

|

|

Suitable PET bottle size

|

Bottle Highness:160~320mm,

|

|

Suitable to caps

|

Bottle neck: PCO28,30 or 38mm

|

|

Washing Water Required

|

2000 liter per hour

|

|

Washing Pressure

|

0.3~0.4Mpa

|

|

Washing time

|

3 seconds

|

|

Working Power

|

380V AC 50HZ 3-phase, (other power supply is available)

|

|

Control Panel Power

|

24V DC

|

|

Filling Pressure

|

0.15-0.35MPa

|

|

Filling Temperature

|

Max.95°C

|

|

Each Filling Nozzle Filing Speed

|

200~250ml per second

|

|

Suitable to fill

|

Hot Drink ( juice, tea ) and other still drink

|

|

Machine Size

|

4700x3320x2700mm ( L * W *H )

|

|

Gross Weight

|

5000kg approximately

|

|

Power

|

Drive motor:5.87kw

|

Other Products

Why choose us?

1. Our company has been engaged in purification technology and application for over 15 years. We are committed to building the best products in China, and constantly researching and improving products.

2. Our product has passed ISO9001 CE authentication.

3. The production process of the product is carried out under the strict quality control system. We have a good quality and good reputation both at home and abroad.

4. From product design to production test, we strictly abide by the company standard, optimize product cost control, carry out functional micro innovation on every small function and performance point, and enhance the added value of products.

Our Service

Apart from pipe and human factors, the whole machine is guaranteed for one year. We promise to provide free accessories for quality problems. We offer cost for parts that exceed the warranty period.

-

PET Bottle Drinking Water Filling Machine 5000 BPH – 14000 BPH For Mineral Water

PET Bottle Drinking Water Filling Machine 5000 BPH – 14000 BPH For Mineral Water

Efficient thermal filler/filling equipment integration rinse...

→ -

300ml-2L PET Bottle Water Filling Machine , Mineral Water Bottling Machine

300ml-2L PET Bottle Water Filling Machine , Mineral Water Bottling Machine

Multifunctional automatic bottle washing, filling and cappin...

→ -

100-5000 BPH Drinking Water Filling Machine Single / Double Nozzle For Pet Bottle

100-5000 BPH Drinking Water Filling Machine Single / Double Nozzle For Pet Bottle

The series of bottled water filling lines is used to produce...

→ -

3 In 1 Automatic Washing Filling Capping Machine For Food / Beverage CE Standard

3 In 1 Automatic Washing Filling Capping Machine For Food / Beverage CE Standard

The machine is mainly used in the beverage filling operation...

→