Live Chat

Click the button6000-12000 BPH Plastic Bottle Blowing Machine Automatic For Mineral Water Bottle

Plastic blow molding machine is a new generation of bottle blowing machine, it is widely used in the manufacture of carbonated beverage bottle, mineral water, pesticide bottle oil cosmetics, jar, hot filling bottles etc. Carbonated bottle, pesticide bottle oil cosmetics, jars and other beverage bottle, cosmetic bottles, medicine bottles, cans, barrels, toolbox, such as plastic model machine can by changing the mold to produce different shapes of bottles.

Products

-

Bag Filling Machine

-

Beverage Filling Line

-

Biscuit Making Machine

-

Biscuit Production Line

-

Bottle Blowing Machine

-

Carbonated Drink Production Line

-

Cosmetic Filling Machine

-

Drink Production Line

-

Drinking Water Filling Machine

-

Drinking Water Production Line

-

Edible Oil Production Line

-

Fruit Juice Processing Line

-

Juice Filling Machine

-

Plastic Injection Molding Machine

-

Snack Food Production Line

-

UHT Milk Processing Line

-

Water Treatment Systems

-

Vertical Packaging Machine

-

Other Packaging Machine

-

Pillow Type Packaging Machine

-

Pre-made Pouch Packing Machinery

-

Measuring Equipment

-

Cup Filling Machines

-

Conveyor Equipment

-

Auxiliary Equipment

| Condition: | New | Application: | Bottle |

|---|---|---|---|

| Plastic Processed: | PE/PET | Blow Moulding Type: | Extrusion Blow Moulding |

| Automatic: | Yes | Color: | Blue/yellow/white/orange |

| Material Application: | PET/PP/HDPE/PVC/LDPE | Station: | Double |

6000-12000 BPH Plastic Bottle Blowing Machine Automatic For Mineral Water Bottle

Product Description

Plastic blow molding machine is a new generation of bottle blowing machine, it is widely used in the manufacture of carbonated beverage bottle, mineral water, pesticide bottle oil cosmetics, jar, hot filling bottles etc. Carbonated bottle, pesticide bottle oil cosmetics, jars and other beverage bottle, cosmetic bottles, medicine bottles, cans, barrels, toolbox, such as plastic model machine can by changing the mold to produce different shapes of bottles.

Product Features

- Preform self-rotation and infrared preheating to ensure the uniform distribution of heat, increase the bottle rate and increase the capacity.

- Low cost, high efficiency, convenient operation and maintenance, thanks to the automatic process.

- Use FESTO cylinder to avoid pollution and noise.

- Safe, reliable and unique valve position design makes the pneumatic drawing in the machine easier to understand.

- Two modes of operation: automatic and manual.

- Easy to install, test, and start.

- Low retention rate: less than 0.2%.

- The ideal cooling system eliminates any defects in the finished bottle.

- Japanese mitsubishi PLC is adopted to ensure the stability and reliability of automation.

- High clamping force and high pressure crank connecting rod lock mode.

- Automatic precast conveyor saves manpower cost.

- The high regulation performance can be adjusted by adjusting the voltage control area in PLC to preheat the preformed billet to adjust the infrared temperature in the preheater and maintain the proper temperature and humidity.

- High safety, each mechanical action is equipped with safety automatic locking device to ensure safe operation of the whole operation.

Specification:

| Name | MT-6000 | |

| Bottle type specification | Cavity | 2 |

| Theory output | 2500-4000 | |

| Max.volume | 2L | |

| Bottle mouth maximum overall diameter | 29-39mm | |

| Bottle biggest diameter | 105mm | |

| Bottle maximum height | 330mm | |

| Power specification | Light tube quantity | 32pcs |

| Light tube power | 1.5KW | |

| Maximum heating power | 49KW | |

| All electric machine installation | 52KW | |

| Actual consumption | 40%–70% | |

|

Air pressure specification

|

Work pressure | 7-9kg/cm2 |

| Low-pressure gas consumption | 1000L/min | |

| Blow bottle pressure | 25-35kg/cm2 | |

| Higher -pressure gas consumption | 3000Ltr/min | |

| Air pressure specification | Work pressure | 7-9 kg/cm2 |

| Temperature range | 10℃ | |

| Consumption | 9000kcal/hr | |

| Forzen water flow | 139L/min | |

|

Machine specification

|

Machine size | 3.3×1.6×1.9 |

| Machine weight | 2000KG | |

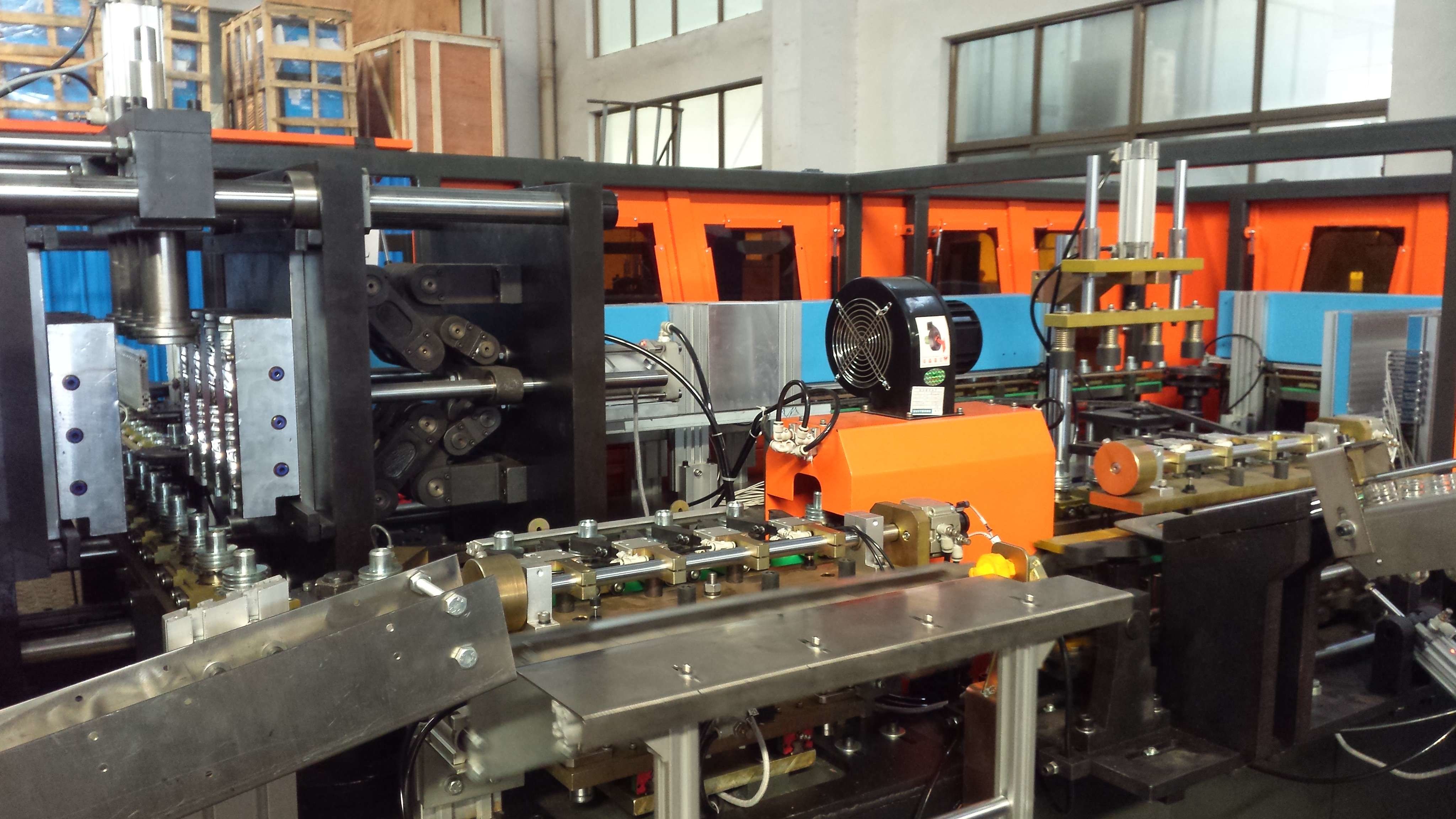

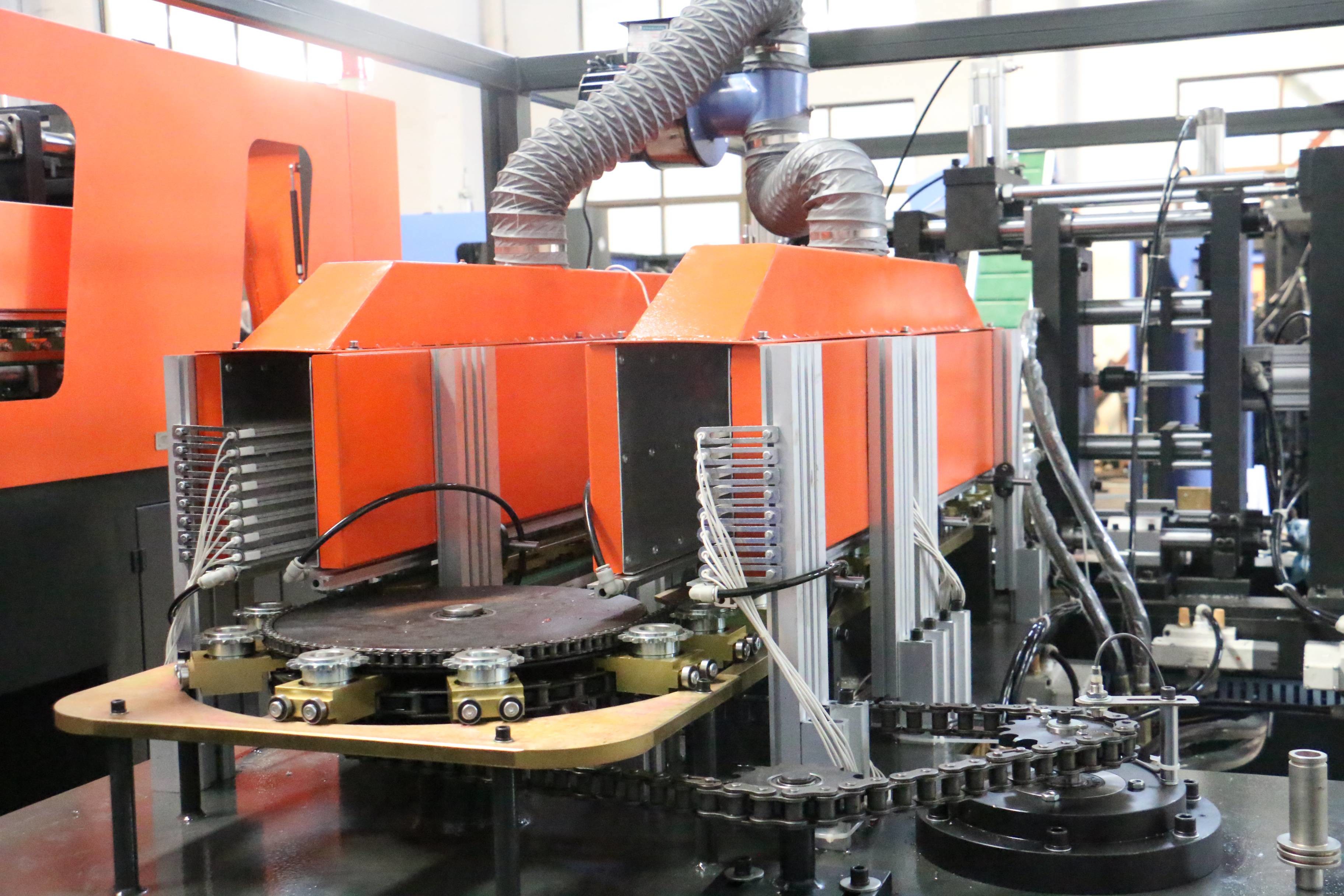

Product Show:

Output Product

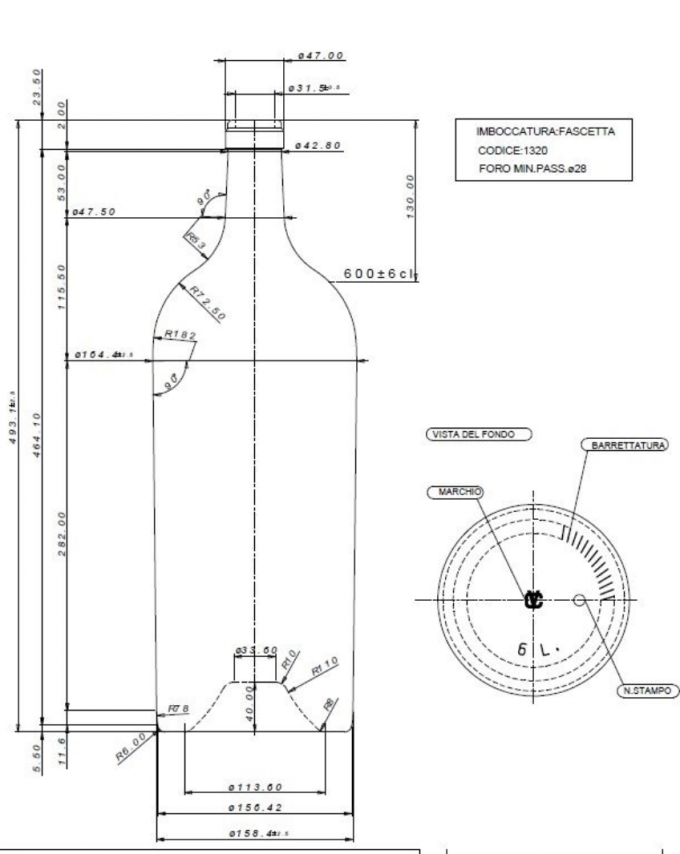

Bottle Design

High quality mold:

Flow Chart

Our Service

- Warranty: one year from the date of installation or acceptance, whichever comes first.

- A year later, we can repair the machine for you. The accessories only provide a cost price.

- Free accessories: digital display instrument, seal, tensioning cylinder sealing ring, mould adjusting wrench, furnace thermometer, heating tube and other vulnerable parts.

- Installation: we could delivery expert engineer for installation in to the buyer's factory. we could also provide debugging ,training service in your factory.

- We can help you design production lines, workshops and provide turnkey projects.

- Free production technology and process configuration.

- Every three years, we can help machine overhaul (labor).

-

Single Stage One Step Extrusion Blow Molding Machine 4 Cavity 250 ml-2000 ml Round bottle

Single Stage One Step Extrusion Blow Molding Machine 4 Cavity 250 ml-2000 ml Round bottle

Plastic bottle blow molding machine is used for the producti...

→ -

Fully Automatic Pet Bottle Blowing Machine / 2500 ML 5 Gallon Bottle Blow Molding Machine

Fully Automatic Pet Bottle Blowing Machine / 2500 ML 5 Gallon Bottle Blow Molding Machine

This 5 gallon bottle blow molding machine is widely used for...

→ -

6000 BPH Water Bottle Blowing Machine / Automatic Stretch Blow Moulding Machine

6000 BPH Water Bottle Blowing Machine / Automatic Stretch Blow Moulding Machine

this bottle blowing machine is widely used for bottle blowin...

→ -

5 Gallon Plastic Bottle Blow Molding Machine 7-30L For Beer Bottle / Jar Bottle

5 Gallon Plastic Bottle Blow Molding Machine 7-30L For Beer Bottle / Jar Bottle

Semi-automatic 5 gallons bottles 5 l - 30 l blow molding mac...

→