Live Chat

Click the buttonSingle Stage One Step Extrusion Blow Molding Machine 4 Cavity 250 ml-2000 ml Round bottle

Plastic bottle blow molding machine is used for the production processing and manufacturing all kinds of PET/PP plastic bottles and other bottles, it is widely used in food, oil, carbonated drinks, mineral water, alcohol, medicine, chemical and other industries, can be used to produce mineral water bottles, beverage bottles, drinks bottles, food bottles and other bottle, the bottle mould design based on customer requirements of bottle shape, weight , the equipment has the advantage of high efficiency, good stability, bottle shape without air bubbles

Products

-

Bag Filling Machine

-

Beverage Filling Line

-

Biscuit Making Machine

-

Biscuit Production Line

-

Bottle Blowing Machine

-

Carbonated Drink Production Line

-

Cosmetic Filling Machine

-

Drink Production Line

-

Drinking Water Filling Machine

-

Drinking Water Production Line

-

Edible Oil Production Line

-

Fruit Juice Processing Line

-

Juice Filling Machine

-

Plastic Injection Molding Machine

-

Snack Food Production Line

-

UHT Milk Processing Line

-

Water Treatment Systems

-

Vertical Packaging Machine

-

Other Packaging Machine

-

Pillow Type Packaging Machine

-

Pre-made Pouch Packing Machinery

-

Measuring Equipment

-

Cup Filling Machines

-

Conveyor Equipment

-

Auxiliary Equipment

| Condition: | New | Application: | Bottle |

|---|---|---|---|

| Plastic Processed: | PP,PE,PVC | Blow Moulding Type: | Extrusion Blow Moulding |

| Automatic: | Yes | Power(W): | Customized |

| Dimension(L*W*H): | By Model | Weight: | 1500kg-5000kg |

| Certification: | CE ISO SGS BV | Warranty: | 24 Months |

| After-sales Service Provided: | Engineers Available To Service Machinery Overseas | Product Name: | HDPE Pet Or Plastic Bottle Blow Molding Machine |

4Cavity 250ml-2000ml Round bottle Auto Single Stage One Step Extrusion Blow Molding Machine

Product Description

Plastic bottle blow molding machine is used for the production processing and manufacturing all kinds of PET/PP plastic bottles and other bottles, it is widely used in food, oil, carbonated drinks, mineral water, alcohol, medicine, chemical and other industries, can be used to produce mineral water bottles, beverage bottles, drinks bottles, food bottles and other bottle, the bottle mould design based on customer requirements of bottle shape, weight , the equipment has the advantage of high efficiency, good stability, bottle shape without air bubbles

Product Features

- Convenient operation and maintenance,

- Improved function and economic investment.

- We can provide the execution and various bottles and covers of 5 gallon and 3gallon bottles to meet customer requirements.

- Small size, compact structure, no space waste.

- One operation.

- Power saving, not easy to wear, adopt the new double crank four connecting rod lock mode, cross fixed.

Specification:

|

Model

|

MT1000B

|

|

|

Theoretical output

|

1600-2000 pcs/h

|

|

|

Finished bottle

|

Max. bottle volume

|

2L

|

|

Max. neck diameter

|

38mm

|

|

|

Max. bottle diameter

|

110mm

|

|

|

Max. bottle height

|

365mm

|

|

|

Mold specifications

|

Cavity

|

2 cavity *2

|

|

Mold thickness

|

110mm-230mm

|

|

|

Open stroke

|

340mm

|

|

|

Electrical system

|

Power voltage

|

380v/3Phase/50HZ

|

|

Installation power

|

14kw

|

|

|

Actual power consumption

|

8kw

|

|

|

Air source

|

Recommend air compressor

|

1.2m³/min 30Kg

|

|

Cooling water

|

Recommend water chiller

|

5HP

|

|

Blower size

|

Length*width*height/weight

|

1590*615*1570mm/650kg (2 sets)

|

|

Heater size

|

Length*width*height/weight

|

1700*565*1360mm/350kg

|

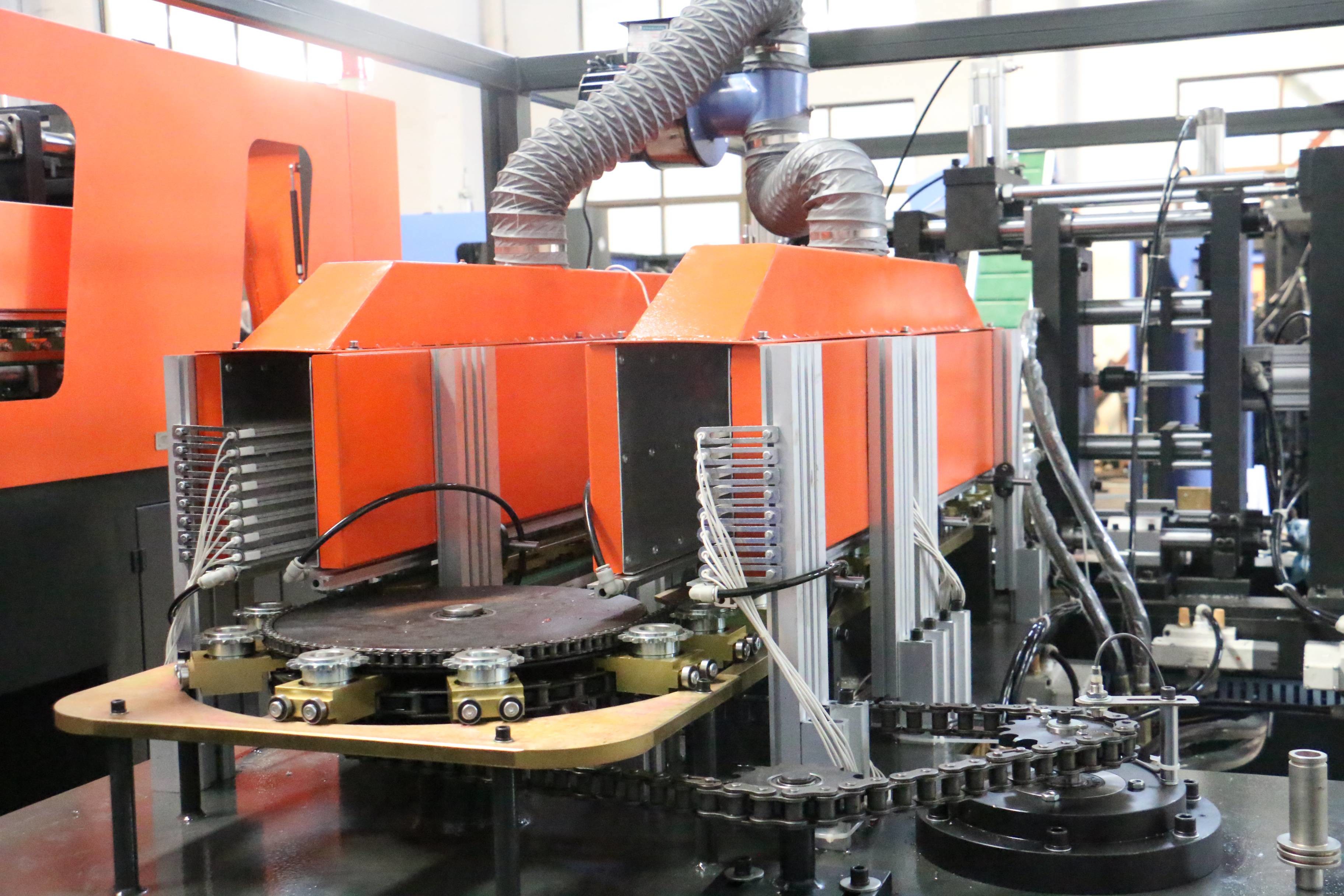

Product Show:

Output Product

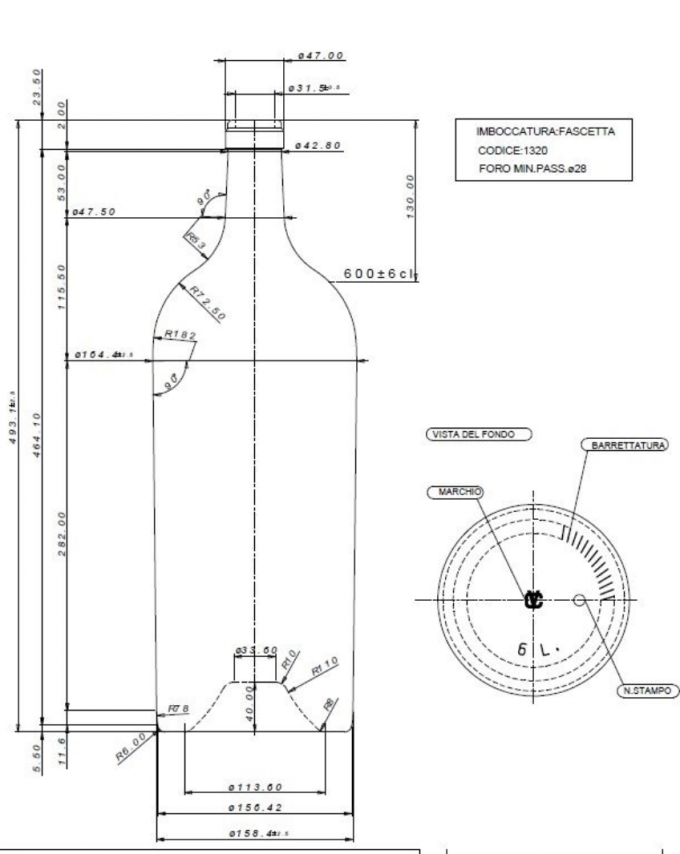

Bottle Design

High quality mold:

Flow Chart

Our Service

- We provide 1 years warranty for whole machine,if you have any problem in first year,we will solve it for free!

- The experienced engineers and technicians are responsible for equipment installation and commissioning to ensure normal production and customers.

- Provide customers with pre-project planning workshop, design, equipment installation, debugging and training.

- To ensure that your technical personnel are familiar with the equipment performance, correct operation and maintenance procedures, master the equipment, provide on-site technical training, so as to facilitate customers to acquire the technology faster and more comprehensively.

-

6000-12000 BPH Plastic Bottle Blowing Machine Automatic For Mineral Water Bottle

6000-12000 BPH Plastic Bottle Blowing Machine Automatic For Mineral Water Bottle

Plastic blow molding machine is a new generation of bottle b...

→ -

Fully Automatic Pet Bottle Blowing Machine / 2500 ML 5 Gallon Bottle Blow Molding Machine

Fully Automatic Pet Bottle Blowing Machine / 2500 ML 5 Gallon Bottle Blow Molding Machine

This 5 gallon bottle blow molding machine is widely used for...

→ -

6000 BPH Water Bottle Blowing Machine / Automatic Stretch Blow Moulding Machine

6000 BPH Water Bottle Blowing Machine / Automatic Stretch Blow Moulding Machine

this bottle blowing machine is widely used for bottle blowin...

→ -

5 Gallon Plastic Bottle Blow Molding Machine 7-30L For Beer Bottle / Jar Bottle

5 Gallon Plastic Bottle Blow Molding Machine 7-30L For Beer Bottle / Jar Bottle

Semi-automatic 5 gallons bottles 5 l - 30 l blow molding mac...

→