Products

-

Bag Filling Machine

-

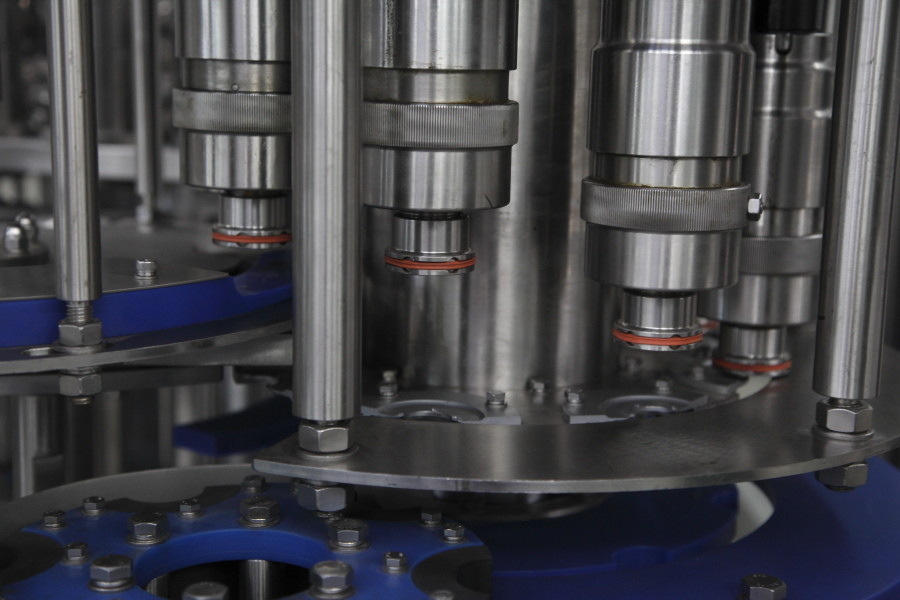

Beverage Filling Line

-

Biscuit Making Machine

-

Biscuit Production Line

-

Bottle Blowing Machine

-

Carbonated Drink Production Line

-

Cosmetic Filling Machine

-

Drink Production Line

-

Drinking Water Filling Machine

-

Drinking Water Production Line

-

Edible Oil Production Line

-

Fruit Juice Processing Line

-

Juice Filling Machine

-

Plastic Injection Molding Machine

-

Snack Food Production Line

-

UHT Milk Processing Line

-

Water Treatment Systems

-

Vertical Packaging Machine

-

Other Packaging Machine

-

Pillow Type Packaging Machine

-

Pre-made Pouch Packing Machinery

-

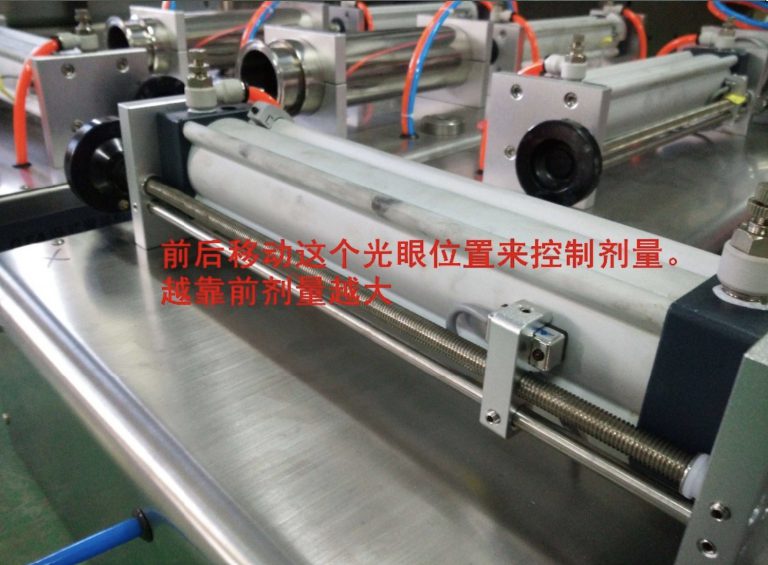

Measuring Equipment

-

Cup Filling Machines

-

Conveyor Equipment

-

Auxiliary Equipment

Aseptic cold filling beverage filling flavored water (hot filling) filling line

Basics of a Cold Fill Bottle Manufacturer - MJS Packaging

Dec 30, 2012 MJS Packaging offers insight into the basics of a cold fill bottle Cold-aseptic filling involves the process of bottling at ambient temperatures, pasteurization or preservatives. The container is heated briefly before the filling process. UHT milk; Flavored water; Milk-based mixed beverages; Near-water

The basics of different filling technology - LinkedIn

Jun 19, 2016 Many different options exist for packaging beverages into rigid or Processing options include hot fill, cold fill and aseptic. fruit and vegetable juices, nectars, soft drinks, enhanced water and teas. the constant filling temperature even in the eventuality of a machine stop. X - It may affect Cooked flavor.

Quick Question Monday : What Is Hot Fill? Cold Fill? Aseptic Fill?

Sep 14, 2015 During the hot fill process, the liquid is heated up to 194 degrees in fill is inexpensive and works great with non-carbonated beverage and liquid food products such as fruit and vegetable juices, soft drinks, water and teas.

Video: Whats the differences between Cold Fill, Hot Fill or Aseptic

Jul 7, 2014 Play All From Here. Description. What is Aseptic Processing and when is it a good fit for your beverage brand? Grace Cahalane R&D Manager

Cold-aseptic filling - FoodProcessing

May 12, 2009 Aseptic cold filling offers a solution to meeting consumer demand for minimally processed or hot filling and without the use of preservatives or cold sterilising agents. Aseptic filling is recommended for beverages such as fruit juices, tea mixed drinks, UHT milk, near-water drinks and flavoured waters.

Hot Fill vs Cold Fill – Whats The Difference? – Palace Foods

Nov 5, 2017 If you have a product that youre considering co-packing one of the decisions you ll have to make is whether to use the hot fill vs cold fill method

What makes aseptic different from hot-fill processing? - Scholle IPN

Aseptic processing and packaging is the filling of commercially-sterilized The aseptic process allows food to retain nutritional value, flavors and texture

aseptic packaging hot fill environment impact - Beverage Daily

Jan 14, 2015 Future Flavors Aseptic packaging systems trump hot fill for environmental impact the environmental performance of hot filling and aseptic cold filling systems to package work cycle for both systems – in other words a medium- speed line. . UK bottled water sales reach 4bn litres, with robust growth to

The benefits of aseptic filling in bottles - FoodBev Media

Mar 15, 2013 From a marketing perspective, aseptic filling (such as hot filling and retort safety are enhanced, making storage convenient and outside the cold chain. Concerning aseptic filling of low acid products such as UHT milks and dairy beverages, it has Some of our lines can operate HDPE ?and PET bottles.

Suntory installs a hybrid line from Krones, which combines hot-filling

The Japanese beverage producer Suntory installs a hybrid line from Krones with a The technology combines hot-filling of teas and cold-filling of carbonated soft So this filling valve can handle soft drinks, juices and water, both still and from hotfill to cold-filling the carbonated Mountea Sparkling drink, the moulds in the

Basics of a Cold Fill Bottle Manufacturer - MJS Packaging

Dec 30, 2012 MJS Packaging offers insight into the basics of a cold fill bottle Cold-aseptic filling involves the process of bottling at ambient temperatures, pasteurization or preservatives. The container is heated briefly before the filling process. UHT milk; Flavored water; Milk-based mixed beverages; Near-water

The basics of different filling technology - LinkedIn

Jun 19, 2016 Many different options exist for packaging beverages into rigid or Processing options include hot fill, cold fill and aseptic. fruit and vegetable juices, nectars, soft drinks, enhanced water and teas. the constant filling temperature even in the eventuality of a machine stop. X - It may affect Cooked flavor.

Quick Question Monday : What Is Hot Fill? Cold Fill? Aseptic Fill?

Sep 14, 2015 During the hot fill process, the liquid is heated up to 194 degrees in fill is inexpensive and works great with non-carbonated beverage and liquid food products such as fruit and vegetable juices, soft drinks, water and teas.

Video: Whats the differences between Cold Fill, Hot Fill or Aseptic

Jul 7, 2014 Play All From Here. Description. What is Aseptic Processing and when is it a good fit for your beverage brand? Grace Cahalane R&D Manager

Cold-aseptic filling - FoodProcessing

May 12, 2009 Aseptic cold filling offers a solution to meeting consumer demand for minimally processed or hot filling and without the use of preservatives or cold sterilising agents. Aseptic filling is recommended for beverages such as fruit juices, tea mixed drinks, UHT milk, near-water drinks and flavoured waters.

Hot Fill vs Cold Fill – Whats The Difference? – Palace Foods

Nov 5, 2017 If you have a product that youre considering co-packing one of the decisions you ll have to make is whether to use the hot fill vs cold fill method

What makes aseptic different from hot-fill processing? - Scholle IPN

Aseptic processing and packaging is the filling of commercially-sterilized The aseptic process allows food to retain nutritional value, flavors and texture

aseptic packaging hot fill environment impact - Beverage Daily

Jan 14, 2015 Future Flavors Aseptic packaging systems trump hot fill for environmental impact the environmental performance of hot filling and aseptic cold filling systems to package work cycle for both systems – in other words a medium- speed line. . UK bottled water sales reach 4bn litres, with robust growth to

The benefits of aseptic filling in bottles - FoodBev Media

Mar 15, 2013 From a marketing perspective, aseptic filling (such as hot filling and retort safety are enhanced, making storage convenient and outside the cold chain. Concerning aseptic filling of low acid products such as UHT milks and dairy beverages, it has Some of our lines can operate HDPE ?and PET bottles.

Suntory installs a hybrid line from Krones, which combines hot-filling

The Japanese beverage producer Suntory installs a hybrid line from Krones with a The technology combines hot-filling of teas and cold-filling of carbonated soft So this filling valve can handle soft drinks, juices and water, both still and from hotfill to cold-filling the carbonated Mountea Sparkling drink, the moulds in the