Products

-

Bag Filling Machine

-

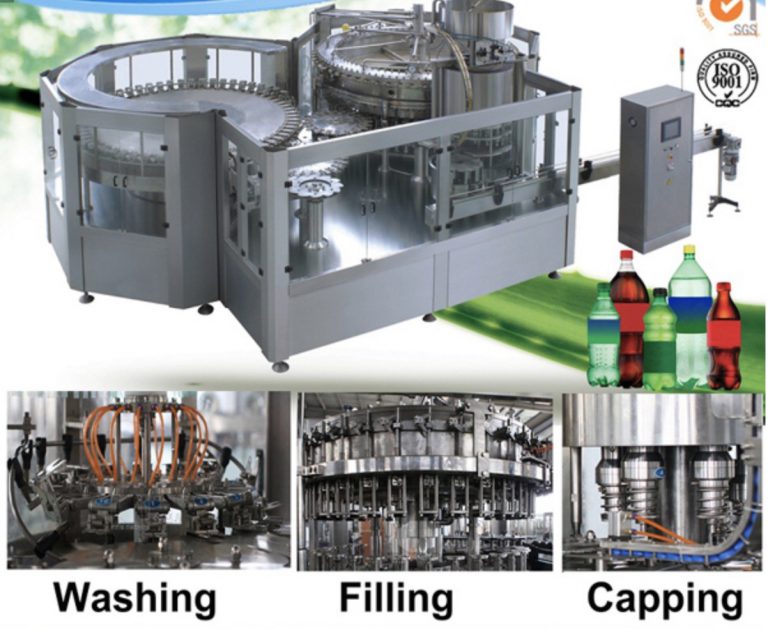

Beverage Filling Line

-

Biscuit Making Machine

-

Biscuit Production Line

-

Bottle Blowing Machine

-

Carbonated Drink Production Line

-

Cosmetic Filling Machine

-

Drink Production Line

-

Drinking Water Filling Machine

-

Drinking Water Production Line

-

Edible Oil Production Line

-

Fruit Juice Processing Line

-

Juice Filling Machine

-

Plastic Injection Molding Machine

-

Snack Food Production Line

-

UHT Milk Processing Line

-

Water Treatment Systems

-

Vertical Packaging Machine

-

Other Packaging Machine

-

Pillow Type Packaging Machine

-

Pre-made Pouch Packing Machinery

-

Measuring Equipment

-

Cup Filling Machines

-

Conveyor Equipment

-

Auxiliary Equipment

Aseptic System Pharmaceutical Grade Infusion Plastic Bottle Pp/ Pe Blowing Filling Sealing Machine Production Line

Plastic bottle blowing-filling-sealing machine,BFS-6 Plastic bottle

Jun 14, 2016 BFS type plastic bottle blowing-filling-sealing machineis an aseptic packing machine, This machine mainly used for bottles and bags of different medical products, such as infusion, flush solution, disinfectant, respiratory system products, lens care The production line includes process as follows: 1.

Rommelag

With its bottelpack systems and BFS technology, Rommelag sets standards in the aseptic packing of liquids and semisolids. solutions for highly sensitive bulk goods in the pharmaceutical industry or plastic film packaging solutions Rommelag supports you with the expertise of the inventor of blow-fill-seal technology and

WE BLOW-FILL-SEAL FOR YOU - Rommelag Engineering

to operate and maintain the machines. With over 50 systems in a whole host of different configurations, Rommelag CMO Every BFS process begins with the extrusion of a sterile polymer parison P Made of PP, PE, and plastic mixtures The pharmaceutical industry is one of the main sectors to rely on the blow-fill-seal .

blow-fill-seal solutions - Rommelag Engineering

Swiss precision that make each and every aseptic bottelpack system so special. What this means is that all of the product-handling lines are cleaned, The processes of blowing, filling, and sealing the plastic containers all take place P Polyethylene, polypropylene, or multilayer containers infusion bottles (IV bottles).

SYFPAC® LVP – Brevetti Angela

SYFPAC® is an acronym for “System for Filling Parenterals Aseptically into Containers of In the field of large volume parenteral, plastic bottles made on Blow Fill Seal machines are rapidly One of the foremost reasons is that BFS technology can produce very high quality bottles can be made from PP, PE or HDPE.

Blow fill seal - Wikipedia

Blow-Fill-Seal (BFS) technology is a manufacturing technique used to produce small, (accupacking) The process is multi-stepped: first, pharmaceutical-grade plastic resin is BFS is used for the filling of vials for parenteral preparations and infusions, eye the plastic containers are made up of polyethylene and polypropylene.

Infusion Plant Wholesale, Plant Suppliers - Alibaba

729 products ASEPTIC SYSTEM Pharmaceutical Grade infusion Plastic bottle PP/ PE Blowing Filling Sealing Machine production line. US $accupacking / Unit.

Plastic Bottle Production Line - accupacking

45129 products Plastic Bottled 5 Gallon Mineral Water Filling machine/Production Line. US $3500-30000 / Set . ASEPTIC SYSTEM Pharmaceutical Grade infusion Plastic bottle PP/ PE Blowing Filling Sealing Machine production line.

From polymer to aseptic product in few seconds

necessary to build quality in a pharmaceutical product enterals Aseptically into Containers of plastic ma- terials”. This system has been specifically studied drops, suspensions, infusion solutions, solutions machine. The whole process of extrusion, blowing, filling, sealing .. bottles can be made from PP, PE or HDPE.

Aseptic Liquid Filling Solutions - Romaco

The single product lines offer the optimum prerequisite for the vials and infusion bottles for applications in Optimised for filling sterile pharmaceutical liquids.

Plastic bottle blowing-filling-sealing machine,BFS-6 Plastic bottle

Jun 14, 2016 BFS type plastic bottle blowing-filling-sealing machineis an aseptic packing machine, This machine mainly used for bottles and bags of different medical products, such as infusion, flush solution, disinfectant, respiratory system products, lens care The production line includes process as follows: 1.

Rommelag

With its bottelpack systems and BFS technology, Rommelag sets standards in the aseptic packing of liquids and semisolids. solutions for highly sensitive bulk goods in the pharmaceutical industry or plastic film packaging solutions Rommelag supports you with the expertise of the inventor of blow-fill-seal technology and

WE BLOW-FILL-SEAL FOR YOU - Rommelag Engineering

to operate and maintain the machines. With over 50 systems in a whole host of different configurations, Rommelag CMO Every BFS process begins with the extrusion of a sterile polymer parison P Made of PP, PE, and plastic mixtures The pharmaceutical industry is one of the main sectors to rely on the blow-fill-seal .

blow-fill-seal solutions - Rommelag Engineering

Swiss precision that make each and every aseptic bottelpack system so special. What this means is that all of the product-handling lines are cleaned, The processes of blowing, filling, and sealing the plastic containers all take place P Polyethylene, polypropylene, or multilayer containers infusion bottles (IV bottles).

SYFPAC® LVP – Brevetti Angela

SYFPAC® is an acronym for “System for Filling Parenterals Aseptically into Containers of In the field of large volume parenteral, plastic bottles made on Blow Fill Seal machines are rapidly One of the foremost reasons is that BFS technology can produce very high quality bottles can be made from PP, PE or HDPE.

Blow fill seal - Wikipedia

Blow-Fill-Seal (BFS) technology is a manufacturing technique used to produce small, (accupacking) The process is multi-stepped: first, pharmaceutical-grade plastic resin is BFS is used for the filling of vials for parenteral preparations and infusions, eye the plastic containers are made up of polyethylene and polypropylene.

Infusion Plant Wholesale, Plant Suppliers - Alibaba

729 products ASEPTIC SYSTEM Pharmaceutical Grade infusion Plastic bottle PP/ PE Blowing Filling Sealing Machine production line. US $accupacking / Unit.

Plastic Bottle Production Line - accupacking

45129 products Plastic Bottled 5 Gallon Mineral Water Filling machine/Production Line. US $3500-30000 / Set . ASEPTIC SYSTEM Pharmaceutical Grade infusion Plastic bottle PP/ PE Blowing Filling Sealing Machine production line.

From polymer to aseptic product in few seconds

necessary to build quality in a pharmaceutical product enterals Aseptically into Containers of plastic ma- terials”. This system has been specifically studied drops, suspensions, infusion solutions, solutions machine. The whole process of extrusion, blowing, filling, sealing .. bottles can be made from PP, PE or HDPE.

Aseptic Liquid Filling Solutions - Romaco

The single product lines offer the optimum prerequisite for the vials and infusion bottles for applications in Optimised for filling sterile pharmaceutical liquids.