Live Chat

Click the buttonFully Automatic Biscuit Making Machine 100-1000 kg/H For Puff Snack / Corn Snack

Raw material Mixer → Automatic Feeder → Twin Screw Extruder → Elevator → Dryer →Automatic Flavoring Line(Powder & Oil)

The Mode and shape of product is totally formed by a combination of the die aperture, including ball, tube, stick, ring, fruit loop, star, wheel and flower ,corn etc.

Products

-

Bag Filling Machine

-

Beverage Filling Line

-

Biscuit Making Machine

-

Biscuit Production Line

-

Bottle Blowing Machine

-

Carbonated Drink Production Line

-

Cosmetic Filling Machine

-

Drink Production Line

-

Drinking Water Filling Machine

-

Drinking Water Production Line

-

Edible Oil Production Line

-

Fruit Juice Processing Line

-

Juice Filling Machine

-

Plastic Injection Molding Machine

-

Snack Food Production Line

-

UHT Milk Processing Line

-

Water Treatment Systems

-

Vertical Packaging Machine

-

Other Packaging Machine

-

Pillow Type Packaging Machine

-

Pre-made Pouch Packing Machinery

-

Measuring Equipment

-

Cup Filling Machines

-

Conveyor Equipment

-

Auxiliary Equipment

| Condition: | Small Scale Biscuit Making Machine | Model Number: | MT-BMK-4002 |

|---|---|---|---|

| Application: | Puff Snack/Corn Snack/Extrusion In Snack Processing | Voltage: | 220/380/450V |

| Power(W): | 22/30/55/75/90kw | Weight: | 3 Ton |

| Size Of Machine(L*W*H): | 30000*5000*3500mm | Certification: | CE,ISO,SGS |

| Material: | 304 And 316 Stainless Steel | Die: | Standard And Can Be Customized |

| Motor: | Siemens | Invertors: | ABB/Delta |

Fully Automatic Biscuit Making Machine 100-1000 kg/H For Puff Snack / Corn Snack

Product Description:

The Snack/Corn Snack Biscuit Making Machine is widely used to puffed snak, corn snack etc.

The material can be corn, rice, wheat, oat, barley etc .

Through friction of screw and barrel, the grains are cooked in the extruder. Forming is at the die face cutter.

The Biscuit Process Processing Line include:

Raw material Mixer → Automatic Feeder → Twin Screw Extruder → Elevator → Dryer →Automatic Flavoring Line(Powder & Oil)

The Mode and shape of product is totally formed by a combination of the die aperture, including ball, tube, stick, ring, fruit loop, star, wheel and flower ,corn etc.

General Formulation:

Corn Powder, Wheat Flour, Bean Powder, Rice Flour and many others

Our Strengths:

Effective:

Automatic techniques for organized and consistent manufacturing on a continuous basis, easy and quick product changeover, automatic set up, easy cleaning up and maintaining processes.

Flexible Formulation:

Application of a wide range of raw materials, such as corn, wheat or grain, rice, potato, oat etc;

Widly Appication:

Easy adaptation to extend the range of products by adjusting the segments screw;

intelligent Control System: PLC Control of production to ensure optimized process parameters for each recipe;

Advanced Die and Slicing system:

This designs give processors an fully new set of design templates to create revolutionary shapes and sizes-Balls, pets, stars, rings, pillows, triangles, curls, chips, sticks, and also letters;

Application:

Our machine is widely used in processing of Puff Snack/Corn Snack/Extrusion In Snack Processing

Machine Parameters:

|

Model |

Installed Power |

Power Consumption |

Capacity/Output |

Dimension |

|

MT-BSM-6002 Twin Screw Extruder |

41.9kw |

30kw |

120-180kg/h |

3070x960x2050mm |

|

MT-BSM-6003 Twin Screw Extruder |

41.3kw |

22kw |

100-150kg/h |

2600x960x2000mm |

|

MT-BSM-6004Twin Screw Extruder |

64.45kw |

40kw |

200-250kg/h |

3320x960x2100mm |

|

MT-BSM-6005 Twin Screw Extruder |

59.05kw |

50kw |

250-350kg/h |

4650x1100x2200mm |

|

MT-BSM-6004 Twin Screw Extruder |

87kw |

72kw |

350-500kg/h |

4800x1100x2300mm |

|

MT-BSM-6008Twin Screw Extruder |

54.3kw |

40kw |

130-160kg/h |

4500x900x1820mm |

|

MT-BSM-60010Twin Screw Extruder |

99.7kw |

67.3kw |

300-400kg/h |

5200x1100x2200mm |

|

MT-BSM-6003 Twin Screw Extruder |

151.3kw |

121kw |

600-800kg/h |

5800x1200x2500mm |

Our Services

Before Buying:

We will supply specialized technological project and sales consultation assistance to solve the customers' issue and concerns;

Through Production: Timely updates the machine state for customer to ensure shipping and delivery time, and quality

After Production:

Equipment testing video clip and photographs will be offered for assessment, if the client cannot come;

Before and through shipping:

the device is going to be cleaned out and packed before shipping; all of the docs will be presented to the purchaser;

Installation & Training:

offering specialized as well as qualified technicians to provide the training and installation assistance.

After Sales Service:

Dedicated department and technical engineers for offering the quick and productive support as soon as the clients' need, such as formulation, parameters establishing, and spare parts;

Product packaging & delivery

Every equipment will be cleaned out and fully wraped by plastic-type material film to prevent any kind of scratch;

Additional repalcement parts

wires and tool kit will be placed with the package;

Deliver Department and sales will check the list to aviod any missing, and possible mistake;

Good quality wooden cases to protect the device for long-tme shipping;

FAQ

1 Where is your manufacturing plant?

Shanghai City , China

2 What is your machine guarantee?

We supply more than 1 year, for spare parts,we supply 2 or 3 years.

3 Do you supply spare parts?

sure, we supply spare part with factory cost;

4.Do you have after sale service for oversea customers?

We will arrange engineers for establishment ,training,they will resovle the all the problem you are facing.

5 If we give you the layout of factory, would you be able to desgin the entire procedure line?

yes, our accomplished architects and technical engineers can help you the design and establishment the whole line according to your layout of factory.

6 How would we be able to contatc you when we have issues of production?

Telephone/email/wechat/whatsapp/Skype are on available at anytime.

7 If we have samples of new items, are you able to design the machine?

Indeed, we can help to investigation, outline and test the new items you advertised.

Our Hot Products

Puff Snack/Corn Snack/Extrusion Snack

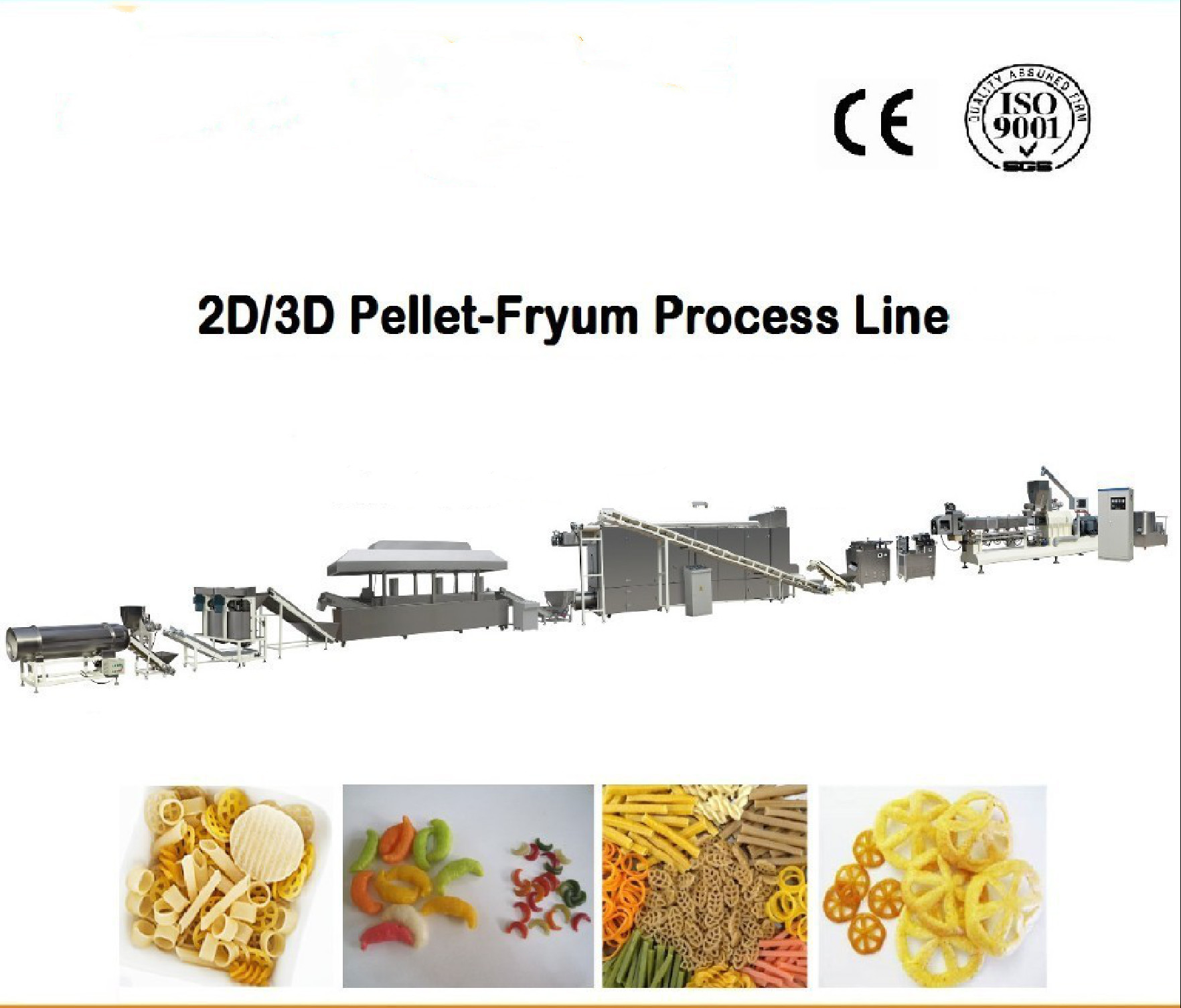

2D/3D Pellet, Fryums, Bugles Snack

American Popcorn/Caramel Popcorn

Double Screw Extruder

-

Snack Cookies Biscuit Production Machine , Wafer Biscuit Production Line For Corn Rice

Snack Cookies Biscuit Production Machine , Wafer Biscuit Production Line For Corn Rice

Automatic Small Snack Cookies Biscuit Making Machine by corn...

→ -

Easy Operation Mini Biscuit Forming Machine Food Grade Stainless Steel Material

Easy Operation Mini Biscuit Forming Machine Food Grade Stainless Steel Material

his machine can extrude all kinds of unique design snacks an...

→ -

Bakery Biscuit Making Machine / Small Capacity Fully Automatic Biscuit Machine

Bakery Biscuit Making Machine / Small Capacity Fully Automatic Biscuit Machine

Automatic Small Biscuit making machine to take wheat flour a...

→ -

Commercial Automatic Biscuit Making Plant Stick And Bone Shape With Starch

Commercial Automatic Biscuit Making Plant Stick And Bone Shape With Starch

We based on the philosophy of "Production first, Service fir...

→