Products

-

Bag Filling Machine

-

Beverage Filling Line

-

Biscuit Making Machine

-

Biscuit Production Line

-

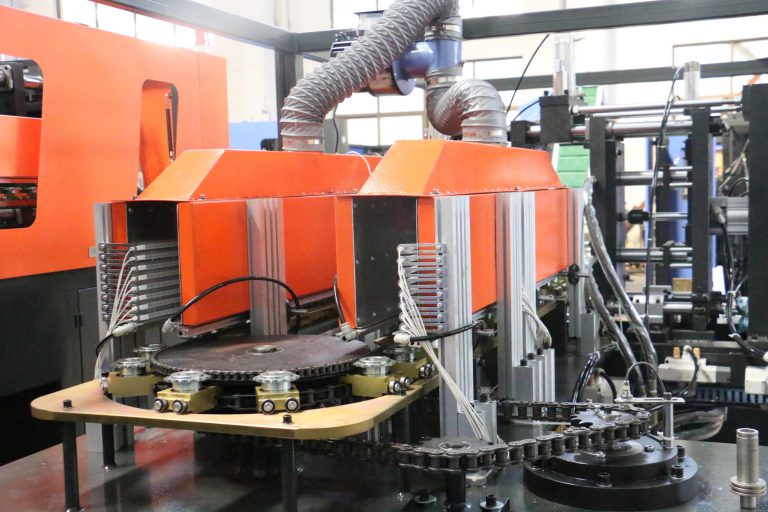

Bottle Blowing Machine

-

Carbonated Drink Production Line

-

Cosmetic Filling Machine

-

Drink Production Line

-

Drinking Water Filling Machine

-

Drinking Water Production Line

-

Edible Oil Production Line

-

Fruit Juice Processing Line

-

Juice Filling Machine

-

Plastic Injection Molding Machine

-

Snack Food Production Line

-

UHT Milk Processing Line

-

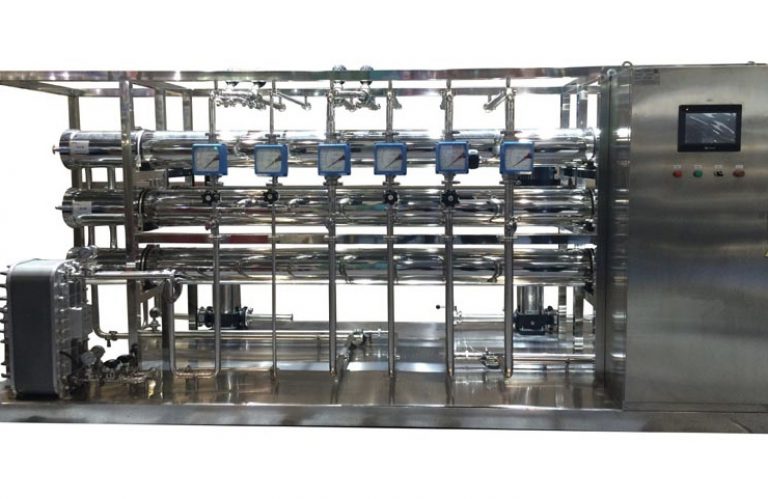

Water Treatment Systems

-

Vertical Packaging Machine

-

Other Packaging Machine

-

Pillow Type Packaging Machine

-

Pre-made Pouch Packing Machinery

-

Measuring Equipment

-

Cup Filling Machines

-

Conveyor Equipment

-

Auxiliary Equipment

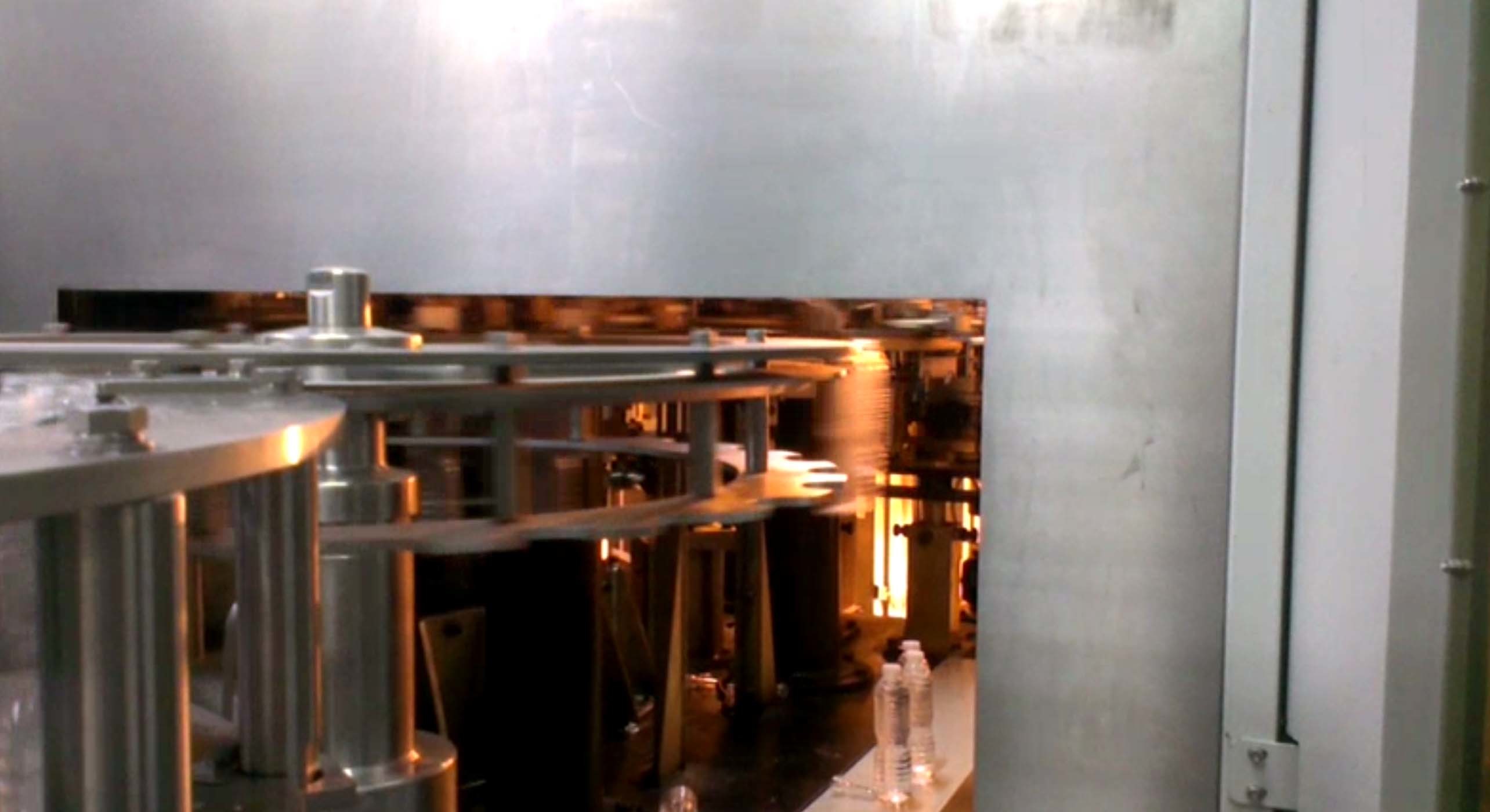

linear beer cans filling line

Mobile & Remote, FMS Solutions - Annex 1, ISO 14644 Solutions

The only complete cleanroom contamination control providers. Instruments & Services. Particle counters, advisory support, calibration, data management, education & more. Contact Us Ask a Question, Get a Quote Find our Local Teams, or Get Help. PMS 20 nm FacilityNet Software PMS Portable Particle Counter Lasair Pro Mobile Particle Counter Cleanroom monitoring, certification Remote Particle Counter IsoAir Pro is ideal for continuous, FMS cleanroom monitoring 0.1 micron for CleanRooms Lasair III 110: Real-time monitor. Laser diode with 1.00 CFM flow rate 10 nm CPC NanoAir Particle counting as low as 10 nm, Ideal for Point of Process.

Supplies From Multiple Brands - Shop Now At accupacking

Grab Exciting Offers and Discounts On an Array Of Products From Popular Brands. Choose From a Wide Range Of Sturdy Tabletops, Available At accupacking. Order Today!

Linear Small Scale Beer Canning Line - YUFENG

This linear beer canning line is used for filling beer in cans, rinser, filler and seamer are separated unit. It can finish all the process such as washing, filling and sealing. It adopts isobaric filling principle and filling valve adopts high precision mechanical valve.

Northland Automation and Engineering Inc - Beer Canning Line

Launched in 2020, the modular canning line by Northland Automation and Engineering is a counter-pressure moduler can filling system. In the demonstration above, it has been setup to fill crowlers, but it can be used to fill standard 12oz or 16oz cans as well.

Canning and Bottling for Craft Brewing: Typical Can Line Layout

A Filler pours beer into the empty cans. A Seamer applies lids to the full beer can. A can Inspection unit identifies cans that have been under-filled and kicks them off the canning conveyor. The Cans flow through a rinse-off tunnel to rinse beer overflow off their exteriors.

Can Filling Line, Can Filling Line Provider - TWELVE WEI

A complete can filling line solution from TWFILLING Machine takes into account every step of your tin aluminum can carbonated drink process, from minimising resource waste to determining your bottle’s ideal look and weight.

Explore ABE Equipment's CraftCan Canning Lines!

Versatile beverage canning lines include counter-pressure filling options. Fill up to 90 cans per minute with our canning machines, perfect for craft beer, canned cocktails, cold brew, and more.

beer cans isobaric filling line - alstonbrew

This linear beer canning line is used for filling beer in cans, rinser, filler and seamer are separated unit. It can finish all the process such as washing, filling and sealing. It adopts isobaric filling principle and filling valve adopts high precision mechanical valve.

Automatic Can Filling Machines | Craft Beverage Canning

Engineered to Fit Small Spaces and Tight Budgets. Our simplified Hybrid can filling technology integrates counter pressure filling and atmospheric filling in an all in one easy to use canning machine. Simply Switch between counter pressure filling & atmospheric filling by the touch of a button.

Mastering Filling Lines for Bottles and Cans - Levapack

In its essence, a filling line is a synchronised array of machinery dedicated to orchestrating a sequence of packaging tasks such as filling, capping, labeling, and packaging within a specific bottle or can.

Beer Canning Line - Things You Need to Know - Levapack

For a clearer picture of the beer canning process, below are the major steps that happen in the production line. Step 1. Feeding of Empty Cans. Depending on the type of machine the line has and the packager’s production demand, this step can be done manually or automatically.

High Speed Canning Lines from IC Filling Systems

You can attach an image or PDF (Max 10MB) High Speed canning lines from IC Filling Systems. Integration, installation, commissioning. Capacity from 2,500 to 50,000 cans per hour.

Pre: care solution liquid full automatic weighing filling line

no article