Products

-

Bag Filling Machine

-

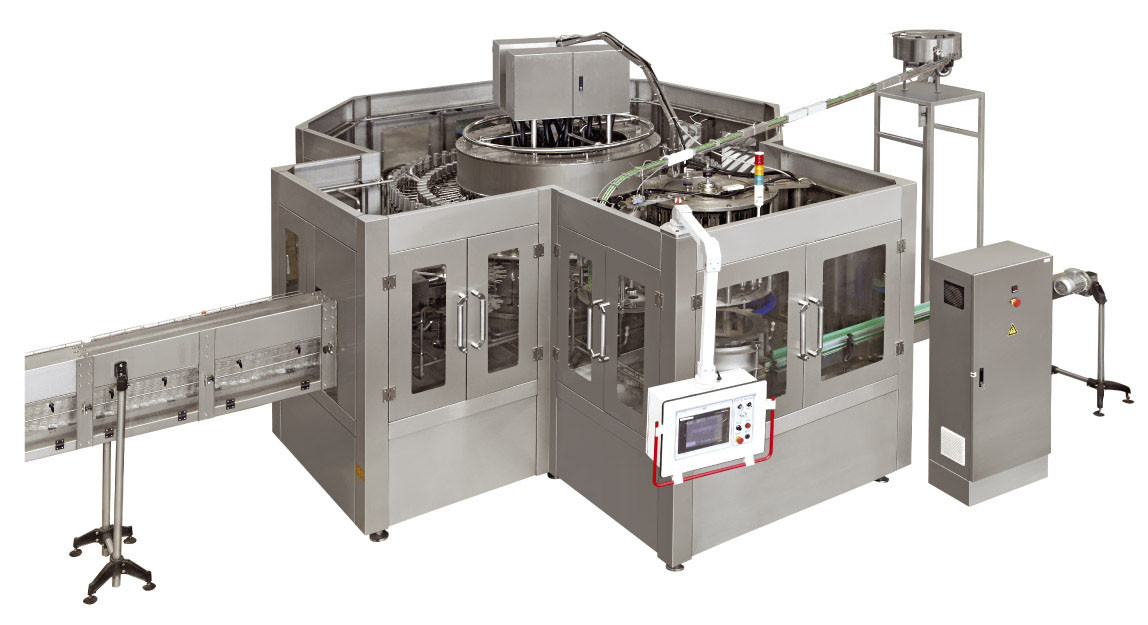

Beverage Filling Line

-

Biscuit Making Machine

-

Biscuit Production Line

-

Bottle Blowing Machine

-

Carbonated Drink Production Line

-

Cosmetic Filling Machine

-

Drink Production Line

-

Drinking Water Filling Machine

-

Drinking Water Production Line

-

Edible Oil Production Line

-

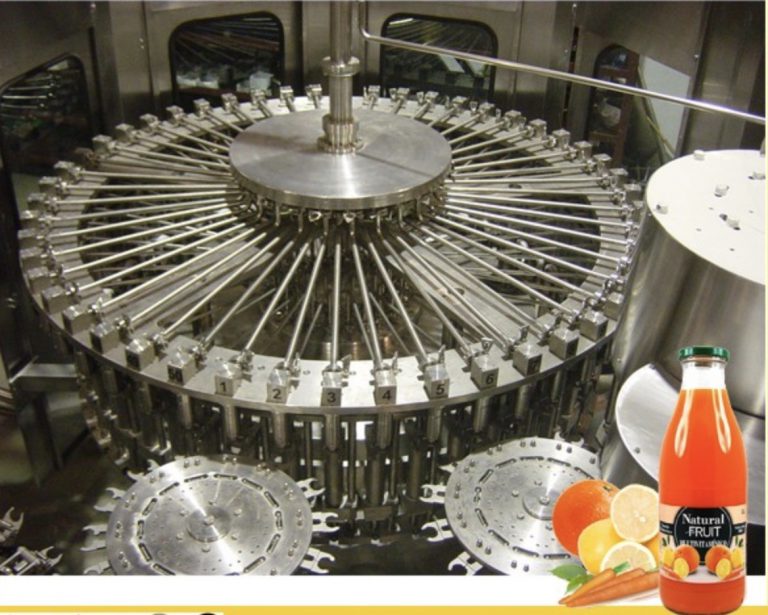

Fruit Juice Processing Line

-

Juice Filling Machine

-

Plastic Injection Molding Machine

-

Snack Food Production Line

-

UHT Milk Processing Line

-

Water Treatment Systems

-

Vertical Packaging Machine

-

Other Packaging Machine

-

Pillow Type Packaging Machine

-

Pre-made Pouch Packing Machinery

-

Measuring Equipment

-

Cup Filling Machines

-

Conveyor Equipment

-

Auxiliary Equipment

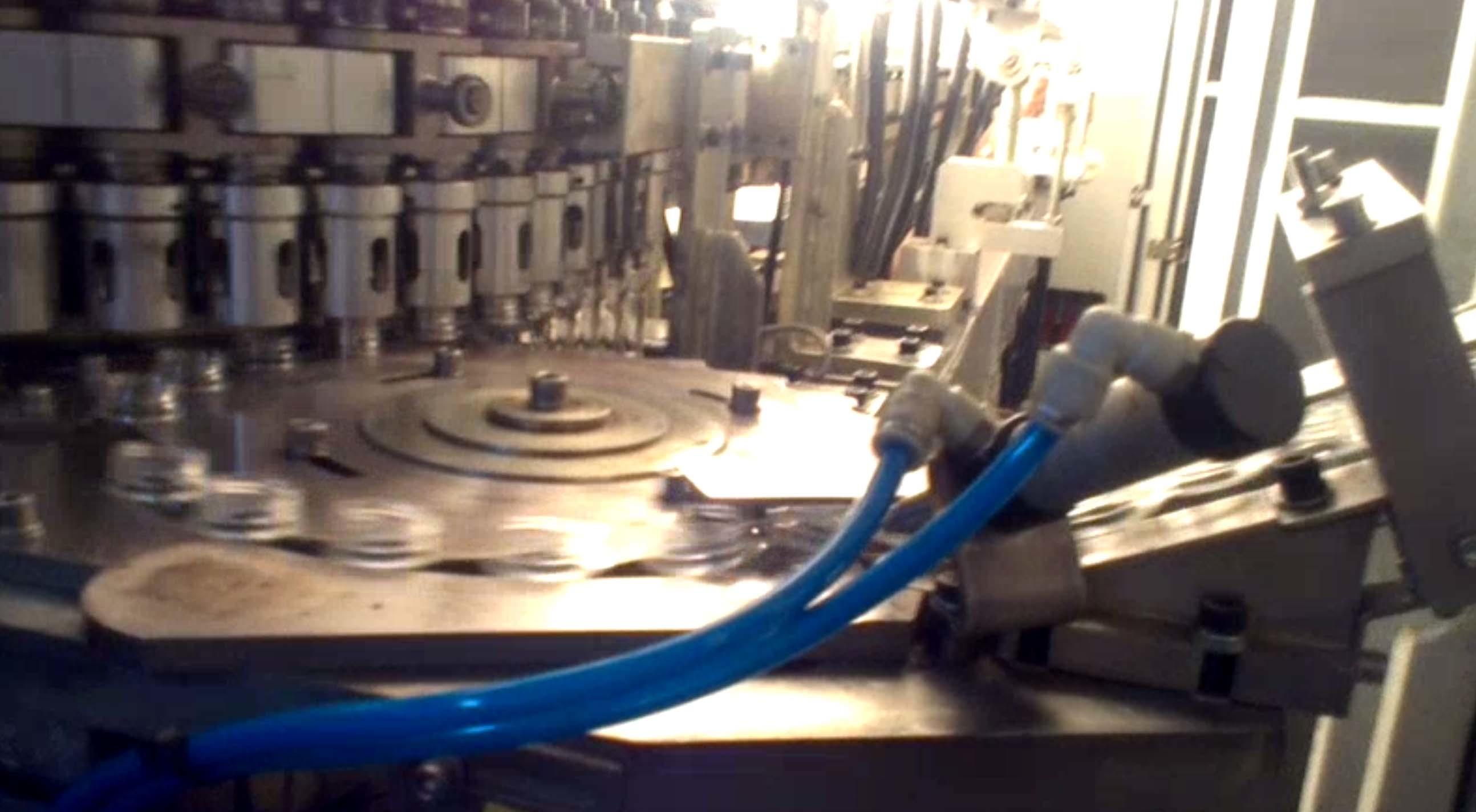

Most Suitable Defoamimg Vinegar Filling Machine with CIP cleaning system

Clean-In-Place (CIP) Systems - Sani-Matic, Inc.

Clean-In-Place (CIP) systems are automated systems used to clean the interior utility requirements for effective and efficient sanitary process equipment cleaning . As a result, appropriate pressure is available to thoroughly remove residue,

Bio-Pharm: Clean-In-Place (CIP) Systems - Sani-Matic, Inc.

Sani-Matic Clean-In-Place (CIP) Systems are engineered to your specific and utility requirements for effective and efficient sanitary process equipment cleaning . CIP design and sizing ensure sufficient flow and appropriate pressure is

Clean-in-place - Wikipedia

Clean-in-place (CIP) is a method of cleaning the interior surfaces of pipes, vessels, process equipment, filters and associated fittings, without disassembly.

Cleaning In Place Machines & How Does CIP - IC Filling Systems

Cleaning in Place is the process of sanitising a filling machine in order to avoid bacteria Initial rinsing of the equipment with clean hot water to remove most particles or Simple, manually operated CIP systems can still be found in use today. to effect good cleaning (applies to pipe circuits and some filled equipment).

CIP – Cleaning in Place - IC Filling Systems

IC Filling Systems offer a complete range of CIP systems (Cleaning-In-Place) suitable from the smallest micro-brewery to the largest bottling plant. Our CIP

Clean-In-Place (CIP) Systems - Sani-Matic, Inc.

Clean-In-Place (CIP) systems are automated systems used to clean the interior utility requirements for effective and efficient sanitary process equipment cleaning . As a result, appropriate pressure is available to thoroughly remove residue,

Bio-Pharm: Clean-In-Place (CIP) Systems - Sani-Matic, Inc.

Sani-Matic Clean-In-Place (CIP) Systems are engineered to your specific and utility requirements for effective and efficient sanitary process equipment cleaning . CIP design and sizing ensure sufficient flow and appropriate pressure is

Clean-in-place - Wikipedia

Clean-in-place (CIP) is a method of cleaning the interior surfaces of pipes, vessels, process equipment, filters and associated fittings, without disassembly.

Cleaning In Place Machines & How Does CIP - IC Filling Systems

Cleaning in Place is the process of sanitising a filling machine in order to avoid bacteria Initial rinsing of the equipment with clean hot water to remove most particles or Simple, manually operated CIP systems can still be found in use today. to effect good cleaning (applies to pipe circuits and some filled equipment).

CIP – Cleaning in Place - IC Filling Systems

IC Filling Systems offer a complete range of CIP systems (Cleaning-In-Place) suitable from the smallest micro-brewery to the largest bottling plant. Our CIP