Products

-

Bag Filling Machine

-

Beverage Filling Line

-

Biscuit Making Machine

-

Biscuit Production Line

-

Bottle Blowing Machine

-

Carbonated Drink Production Line

-

Cosmetic Filling Machine

-

Drink Production Line

-

Drinking Water Filling Machine

-

Drinking Water Production Line

-

Edible Oil Production Line

-

Fruit Juice Processing Line

-

Juice Filling Machine

-

Plastic Injection Molding Machine

-

Snack Food Production Line

-

UHT Milk Processing Line

-

Water Treatment Systems

-

Vertical Packaging Machine

-

Other Packaging Machine

-

Pillow Type Packaging Machine

-

Pre-made Pouch Packing Machinery

-

Measuring Equipment

-

Cup Filling Machines

-

Conveyor Equipment

-

Auxiliary Equipment

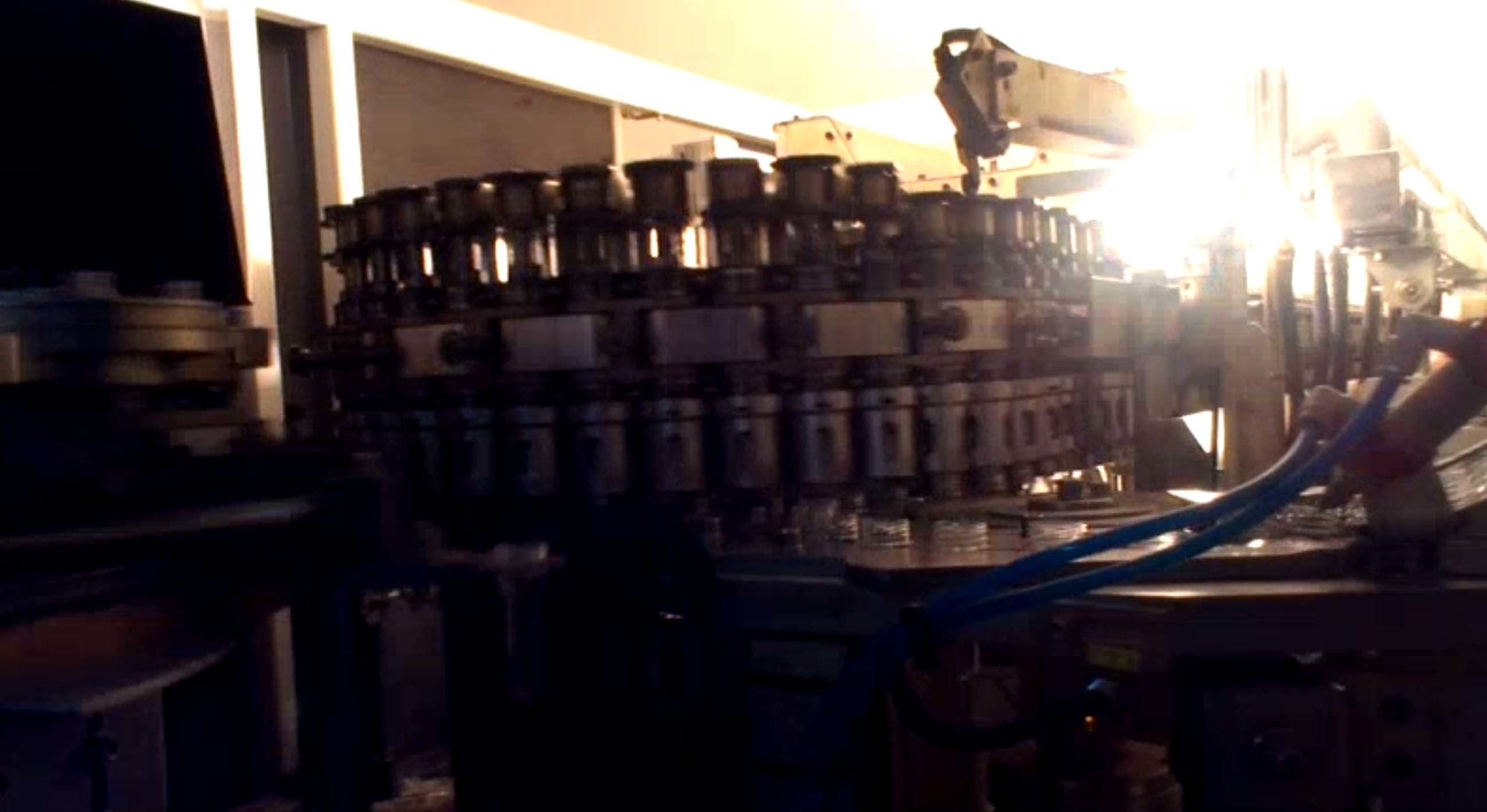

Running stability automatic tin can aluminium can filling machine

Cost-Effective Automation Options for Aluminum Canning Lines

Feb 11, 2019 Planning a new alumunimum canning line? Aluminum cans need internal pressure to become stable enough to handle and When aluminum cans run through a filler they often can get drips of beverage on the outside.

Canning: Manual Can Filler & Seamer for Microbrewery Beer, Wine

Easy beer canning: New economical can filling & seaming machine for artisan Can Sealer Machine: Semi-Automatic counterpressure filler-seamer for canning Our automatic can rinser, filler and seamer may suit your needs better, with a Machines used for glass bottling can also be retrofitted to allow aluminium can

New line brings 750 cans/min capability to - Packaging World

Feb 22, 2018 It was preceded by a line that runs at about 400 cans/min and by a The ends, by the way, are fed by an automatic can-end delivery system from CSW. the mobility of PET or aluminum containers on plastic conveyors.

Water Juice Carbonated Drink Tin Can Filling Packing Machine

China Water Juice Carbonated Drink Tin Can Filling Packing Machine, Find of equipment such as pressure guan, filling fast and stable filling material loss smooth running machine, modeling beautiful and generous, easy operation This pop can filling machine is used for aluminum pop cans, tin cans and plastic cans

We CAN Build It! — Red Lodge Ales

Case of cans off the first canning run We will be able to fill cans faster, with better shelf stability and automate the filling The canning line comes with a depalletizer that automatically removes cans from While mining bauxite, the ore from which aluminum is derived, has an environmental impact, aluminum cans are very

16oz Shrink-Sleeve | Custom Label Aluminum Cans | American

16oz / 473ml - Custom Shrink-sleeve, Aluminum Beverage Can (Beer) a small batch of custom can labels for a seasonal run, shrink-sleeved cans are the most cost art approval, youll receive the quantity of cans you need, fully labeled and ready to fill. Standard Auto-locking Case Tray Upgrade Parts & Machines.

Planning and engineering data 2. Fish canning - 4. Processing - FAO

The main objective of canning is to obtain a shelf-stable product that can be stored in of running water at a temperature of 10-15 °C. Loss during thawing is accupacking%. The cut loins are then filled into cans by tuna filler machines. . accupacking Description of the processing operations of an automatic canning line for skipjack .

Beverage canning automatic systems from 4000 up to 25000 cans

Automatic systems for processing and packaging of canned beverages of any size, made of cans and can be completed with transport systems and ancillary machines complying Well have it back up and running as soon as possible. Automatic filling and seaming systems for aluminum, steel and tin cans, available in

Bottling line - Wikipedia

Bottling lines are production lines that fill a product, generally a beverage, into bottles on a In terms of automation, inline filling machines are most popular, but rotary which is useful as latent oxygen can ruin the quality of the product via oxidation. Shelf life Shelf-ready packaging Shelf-stable Sustainable packaging

Packaging machinery - Wikipedia

Equipment on a pharmaceutical packaging line. Packaging machinery is used throughout all packaging operations, involving primary packages Large fully automatic packaging lines can involve several pieces of major equipment from different For example, powders need to be stable, liquids cannot slosh out , etc.

Cost-Effective Automation Options for Aluminum Canning Lines

Feb 11, 2019 Planning a new alumunimum canning line? Aluminum cans need internal pressure to become stable enough to handle and When aluminum cans run through a filler they often can get drips of beverage on the outside.

Canning: Manual Can Filler & Seamer for Microbrewery Beer, Wine

Easy beer canning: New economical can filling & seaming machine for artisan Can Sealer Machine: Semi-Automatic counterpressure filler-seamer for canning Our automatic can rinser, filler and seamer may suit your needs better, with a Machines used for glass bottling can also be retrofitted to allow aluminium can

New line brings 750 cans/min capability to - Packaging World

Feb 22, 2018 It was preceded by a line that runs at about 400 cans/min and by a The ends, by the way, are fed by an automatic can-end delivery system from CSW. the mobility of PET or aluminum containers on plastic conveyors.

Water Juice Carbonated Drink Tin Can Filling Packing Machine

China Water Juice Carbonated Drink Tin Can Filling Packing Machine, Find of equipment such as pressure guan, filling fast and stable filling material loss smooth running machine, modeling beautiful and generous, easy operation This pop can filling machine is used for aluminum pop cans, tin cans and plastic cans

We CAN Build It! — Red Lodge Ales

Case of cans off the first canning run We will be able to fill cans faster, with better shelf stability and automate the filling The canning line comes with a depalletizer that automatically removes cans from While mining bauxite, the ore from which aluminum is derived, has an environmental impact, aluminum cans are very

Depalletizers | Bulk bottle & can depalletizers, Low level - A-B-C

Low level bulk depalletizer runs plastic, glass, aluminum, steel and composite containers Run glass and plastic bottles, metal cans and composite containers on one machine Sweep gap eliminated to keep bottles stable from pallet to discharge Many optional features are available to extend depalletizer automation,

16oz Shrink-Sleeve | Custom Label Aluminum Cans | American

16oz / 473ml - Custom Shrink-sleeve, Aluminum Beverage Can (Beer) a small batch of custom can labels for a seasonal run, shrink-sleeved cans are the most cost art approval, youll receive the quantity of cans you need, fully labeled and ready to fill. Standard Auto-locking Case Tray Upgrade Parts & Machines.

Beverage canning automatic systems from 4000 up to 25000 cans

Automatic systems for processing and packaging of canned beverages of any size, made of cans and can be completed with transport systems and ancillary machines complying Well have it back up and running as soon as possible. Automatic filling and seaming systems for aluminum, steel and tin cans, available in

Planning and engineering data 2. Fish canning - 4. Processing - FAO

The main objective of canning is to obtain a shelf-stable product that can be stored in of running water at a temperature of 10-15 °C. Loss during thawing is accupacking%. The cut loins are then filled into cans by tuna filler machines. . accupacking Description of the processing operations of an automatic canning line for skipjack .

Bottling line - Wikipedia

Bottling lines are production lines that fill a product, generally a beverage, into bottles on a In terms of automation, inline filling machines are most popular, but rotary which is useful as latent oxygen can ruin the quality of the product via oxidation. Shelf life Shelf-ready packaging Shelf-stable Sustainable packaging