Live Chat

Click the buttonStainless Steel Carbonated Beverage Filling Machine , Fully Automatic Soda Filling Machine

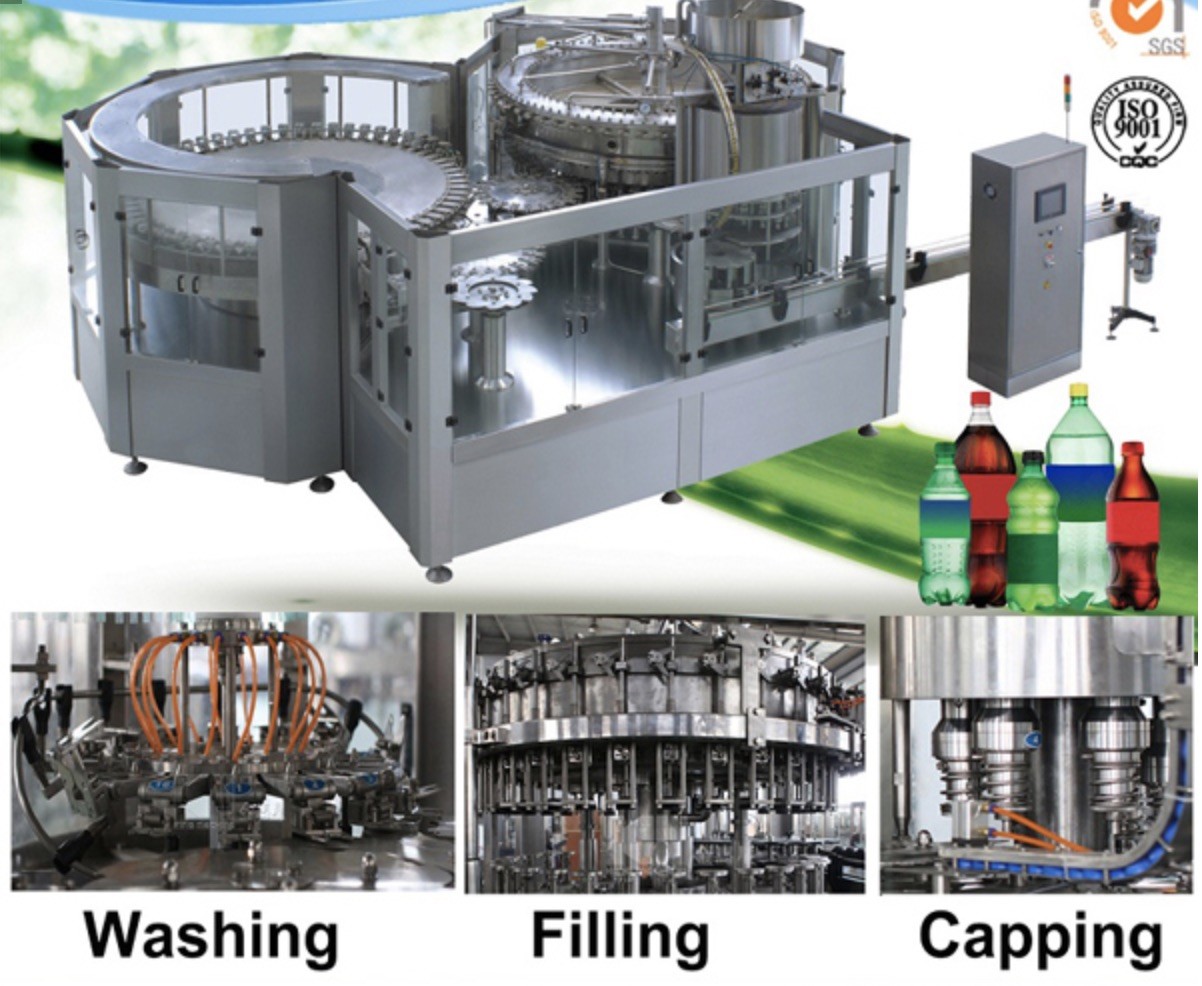

This equipment is mainly used for filling all kinds of carbonated drinks, including Coca-Cola, Sprite, 7-up, such as the integration of the main function of the filling production line equipment, including rinsing, filling and capping, the whole operation process is controlled by PLC, highly automated, suitable for filling the PET or other plastic bottle, glass bottle. Using ISO pressure (ISO pressure) filling technology, the filling process is more efficient, more stable, energy saving and higher production.

Products

-

Bag Filling Machine

-

Beverage Filling Line

-

Biscuit Making Machine

-

Biscuit Production Line

-

Bottle Blowing Machine

-

Carbonated Drink Production Line

-

Cosmetic Filling Machine

-

Drink Production Line

-

Drinking Water Filling Machine

-

Drinking Water Production Line

-

Edible Oil Production Line

-

Fruit Juice Processing Line

-

Juice Filling Machine

-

Plastic Injection Molding Machine

-

Snack Food Production Line

-

UHT Milk Processing Line

-

Water Treatment Systems

-

Vertical Packaging Machine

-

Other Packaging Machine

-

Pillow Type Packaging Machine

-

Pre-made Pouch Packing Machinery

-

Measuring Equipment

-

Cup Filling Machines

-

Conveyor Equipment

-

Auxiliary Equipment

3 In 1 Plastic Bottle Beverage Filling Machine , Automatic Soft Drink Filling Machine

Red Bull Energy Drink Production Line Automatic For Glass / PET Bottle

Fully Automatic Drinking Water Filling Machine 600-3000BPH For 5 Gallon PET Bottle

Bottled Mineral Drinking Water Production Machine / Filling Production Line

SUS304 PET Bottle Edible Oil Bottle Filling Machine For Non Viscous Liquid Filling

| Type: | Water Bottle Filling Machine | Condition: | New |

|---|---|---|---|

| Application: | Food, Beverage, Chemical, Carbonated Beverage | Bottle Type: | Small Square Bottle,round Bottle,flat Bottle,cup Bottle,glass Botte |

| Bottle Size: | 0.1-2.5L | Name: | Carbonated Drink Production Line / Soda Filling Machine |

| Capacity: | 3000-40000bph | Filling Head: | 12-80 |

Fully Automatic Stainless Steel Carbonated Beverage Production Line / Soda Beverage Filling Machine

Application

This equipment is mainly used for filling all kinds of carbonated drinks, including Coca-Cola, Sprite, 7-up, such as the integration of the main function of the filling production line equipment, including rinsing, filling and capping, the whole operation process is controlled by PLC, highly automated, suitable for filling the PET or other plastic bottle, glass bottle. Using ISO pressure (ISO pressure) filling technology, the filling process is more efficient, more stable, energy saving and higher production.

Product Description

- High automation, the equipment adopts omron PLC to realize automatic control of the whole process, and adopts the new type of bottled air pressure control, which isfast and no bottle breakage.

- Multi-purpose, for different shapes of bottles, it can adapt different bottle shape filling by replacing a few parts,

- Special stainless steel washing machine, strong and durable, no touch the screw position of the bottle, to ensure food health and avoid secondary pollution.

- High speed large flow valve filling valve, filling speed is fast, filling accuracy is high,

- The output bottle adopts the specific spiral descending mode, and the transformation bottle shape is not necessary to adjust the height of the conveyor chain, so it is convenient and quick.

- The machine adopts advanced PLC automatic control technology, and the core electrical components are introduced to famous brands such as mitsubishi of Japan, schneider of France and omron.

Specification

| Model | DMT40-40-40 | DMT48-48-12 | DMT60-60-15 | DMT80-80-20 | |

| Heads of washing, filling, sealing | 40-40-10 | 48-48-12 | 60-60-15 | 80-80-20 | |

| Production capacity(bottle/hour) | 16000-18000 | 20000-24000 | 24000-28000 | 46000-40000 | |

| Suitable bottle height(mm) | |||||

| Spraying pressure | |||||

| Total Power(kw) | 7.5 | 11 | 15 | 19 | |

| Overall dimension(L*W*H)(mm) | 4000*4400*4400 | 4850*4650*4400 | 6500*5400*4500 | 7650*6400*2700 | |

| Weight(kg) | 8500 | 1000 | 12500 | 16000 | |

Main components:

- The transfer system between rinsing and filling;

- Electrical system.

- Unloading system;

- Sealing system;

- The transfer system between filling and sealing;

- Drive system;

- Bottle washing system; Bottling system;

- Framework; filling system;

Product Show

Output Product

Our service

The training

- Our company provides technical training for customers. Including equipment operation, maintenance, use of relevant skills, training in the customer workshop.

- We ensure that after the training, your technical personnel can master the skills of operation and maintenance, adjust and so on, and they can query related errors according to the document, and solve the problem in time.

Quality assurance

- After our equipment is shipped to the customer's factory, we will send engineers to your workshop and arrange the equipment according to the provided plane. Through, debugging and ensuring the equipment can operate normally.

- We provide 12 months of quality assurance ,it means we will provide the easy-damage parts free of charge within one year, and we will provide the other parts at the lowest price after one year.

- In terms of quality assurance, the buyer's technical personnel shall operate and maintain the equipment and resolve the problem. and we promise to help you to solve your problems. If necessary, we can arrange engineering to solve problems in your factory.

-

3 In 1 Automatic Soda Water Filling Machine , Small Carbonated Soft Drink Filling Machine

3 In 1 Automatic Soda Water Filling Machine , Small Carbonated Soft Drink Filling Machine

The carbonated drink filling machine used for prouction of...

→ -

Turnkey Project CSD Carbonated Drink Production Line High Capacity 8000 BPH – 15000 BPH

Turnkey Project CSD Carbonated Drink Production Line High Capacity 8000 BPH – 15000 BPH

Complete CSD carbonated filling line has the 3 function of w...

→ -

High Efficiency Carbonated Drink Production Line Washing Filling And Capping Machine

High Efficiency Carbonated Drink Production Line Washing Filling And Capping Machine

The drinking water filling machine adopts the bottleneck har...

→ -

Pepsi Carbonated Soft Drink Filling Machine , Pet Bottle Soda Filling Machine

Pepsi Carbonated Soft Drink Filling Machine , Pet Bottle Soda Filling Machine

Our company focus on providing carbonated beverage bottle fi...

→