Live Chat

Click the buttonTurnkey Project CSD Carbonated Drink Production Line High Capacity 8000 BPH – 15000 BPH

Complete CSD carbonated filling line has the 3 function of washin,filling,capping,it is a fully automatic , high efficiency liquid packaging equipment ,Suitable for beverage packaging containing gas, using the programmable controller to realize from the bottle into the automatic control of finishing packaging, use of frequency converter as a governor, a user can easily adjust the machine to adapt to the different power requirements. The pressure filling principle and current spring valve are adopted to guarantee the quality of beverage.

Products

-

Bag Filling Machine

-

Beverage Filling Line

-

Biscuit Making Machine

-

Biscuit Production Line

-

Bottle Blowing Machine

-

Carbonated Drink Production Line

-

Cosmetic Filling Machine

-

Drink Production Line

-

Drinking Water Filling Machine

-

Drinking Water Production Line

-

Edible Oil Production Line

-

Fruit Juice Processing Line

-

Juice Filling Machine

-

Plastic Injection Molding Machine

-

Snack Food Production Line

-

UHT Milk Processing Line

-

Water Treatment Systems

-

Vertical Packaging Machine

-

Other Packaging Machine

-

Pillow Type Packaging Machine

-

Pre-made Pouch Packing Machinery

-

Measuring Equipment

-

Cup Filling Machines

-

Conveyor Equipment

-

Auxiliary Equipment

| Type: | Water Bottle Filling Machine | Condition: | New |

|---|---|---|---|

| Packaging Type: | Bottles | Automatic Grade: | Automatic |

| After-sales Service Provided: | Engineers Available To Service Machinery Overseas | Product Name: | Soft Drink Filling Machine |

| Degree Of Automation: | Full Auotmatic | Contactor/ Air Switch/supply: | Schneider |

Turnkey Project High Capacity 8000BPH – 15000BPH CSD Carbonated Drink Machine /Production Line Commercial For Bottle

Product Description

Complete CSD carbonated filling line has the 3 function of washin,filling,capping,it is a fully automatic , high efficiency liquid packaging equipment ,Suitable for beverage packaging containing gas, using the programmable controller to realize from the bottle into the automatic control of finishing packaging, use of frequency converter as a governor, a user can easily adjust the machine to adapt to the different power requirements. The pressure filling principle and current spring valve are adopted to guarantee the quality of beverage. Using the advanced magnetic coupler to adjust the tightening torque to ensure the quality of the cover is the first choice for small and medium beverage enterprises.

Product Advantage

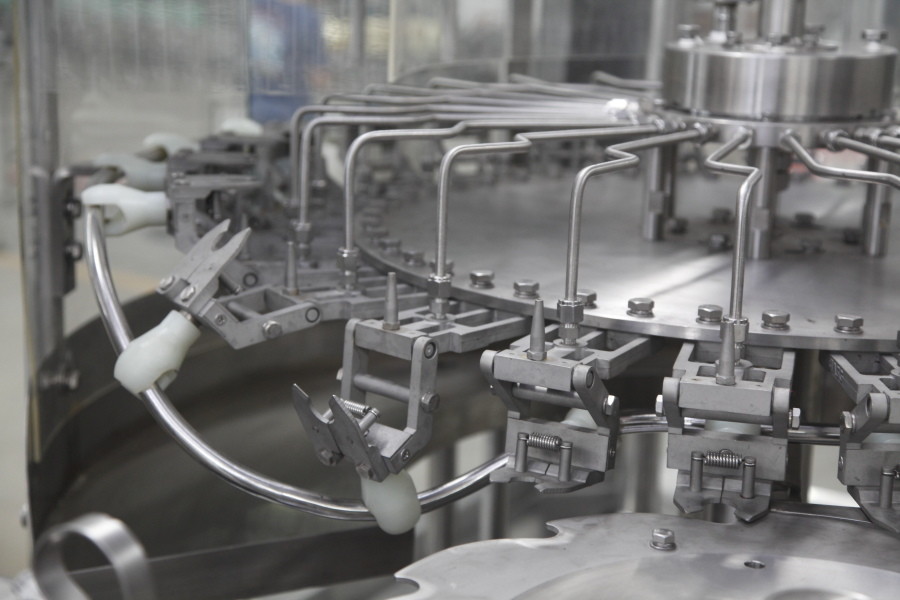

- The filling machine is advanced, concise, reasonable drive and lift drive is located in stainless steel workbench,it is reliable, convenient to adjust and maintain

- The pneumatic filling valve is equipped with interchangeable horizontal pipe for the best filling accuracy, and filling level bottle adjustment.

- On the basis of foreign advanced technology, the filling valve of high speed hot filling is designed. Use guide sleeve to ensure valve opening and closing. The valve is simple in structure, easy to clean and has automatic cleaning function.

- Because of the new type of micro-pressure filling system, the filling operation is faster and more stable.

- Using negative pressure filling, designed for CSD filling, ensure the minimum CO2 loss of the product.

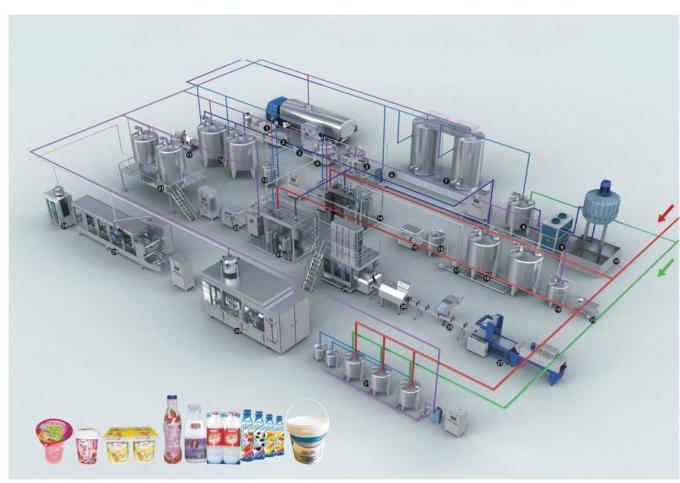

Flow Chart

We are able to supply whole production including :

Water treatment system

– Blow molding machine

– CSD preparation and mixing system

– Bottle unscrambler/Manual bottle loading system

– Air conveyor

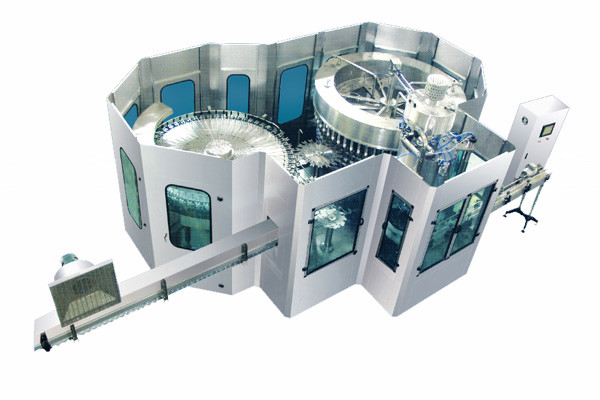

– Rinsing-filling-capping 3-in-1 monoblock

– Bottle Warmer

– Labeling Machine

– Water Blow Drier,

– Lampinspection,

– Code ink jetter

– Shrink wrapper / carton packaging machine

– Palletizing system

– Conveying System

Product Sepcifications

| Main Technical parameters | |||||||

| Model |

MT1 6106 |

MT1 8186 |

MT2 4248 |

MT3 2328 |

MT40 4010 |

MT48 4810 |

MT60 6015 |

| Filler/Capper heads | 16-10-6 | 18-18-6 | 24-24-8 | 32-32-8 | 40-40-10 | 48-48-10 | 60-60-15 |

| Bottle diameter(mm) | Φ=50-100 H=170 330-1500ML | Φ50-Φ110 | H=160-340 | ||||

| Production capacity (b/h) | 2000-4000 | 4000-7000 | 8000-10000 | 10000-10500 | 10500-15000 | 16000-20000 | 20000-24000 |

|

Filling temperature () |

0-5 | ||||||

| Filler type | Balanced pressure filler | ||||||

| Spraying pressure | 0.2-0.25 | 0.2-0.25 | |||||

| Filling pressure | 0.15-0.35 | 0.15-0.35 | 0.15-0.35 | ||||

| Motor power(kw) |

1.5+0.10+ 0.45 |

2.2+0.55+ 0.45 |

3+0.37+ 0.55 |

7.5 | 8.6 | 11 | 15 |

|

Overall dimension( L×W×H)mm |

2300× 1600 ×2500 |

2460× 1860 ×2650 |

3100× 2100 ×2650 |

4350× 2880 ×3200 |

4850× 3800 ×3200 |

5000× 4000 ×3300 |

6500× 5800 ×3200 |

| weight kg | 2800 | 3650 | 4800 | 6000 | 7500 | 9800 | 11500 |

Product Pictures

OutPut Product

Packaging & delivery

Contact Us

Send you inquery now!we will make a business proposal for you in 12hours!

-

Commercial Automatic Carbonated Drink Production Line Big Capacity For Coca – Cola

Commercial Automatic Carbonated Drink Production Line Big Capacity For Coca – Cola

Automatic Carbonated Soft Drinks (CSD) Drink Production Line...

→ -

PLC Controlled Carbonated Drink Production Line / Carbonated Soda Filling Machine

PLC Controlled Carbonated Drink Production Line / Carbonated Soda Filling Machine

THis CGF washing and filling cover 3-in-1unit: beverage mach...

→ -

High Speed Carbonated Drink Production Line / Water Bottle Filling Machine

High Speed Carbonated Drink Production Line / Water Bottle Filling Machine

This production line has been developed on the basis of G...

→ -

Small Scale Soda Bottling Equipment , Carbonated Soft Drink Production Line Glass Bottle

Small Scale Soda Bottling Equipment , Carbonated Soft Drink Production Line Glass Bottle

The whole machine adopts PLC computer program control and ma...

→