Products

-

Bag Filling Machine

-

Beverage Filling Line

-

Biscuit Making Machine

-

Biscuit Production Line

-

Bottle Blowing Machine

-

Carbonated Drink Production Line

-

Cosmetic Filling Machine

-

Drink Production Line

-

Drinking Water Filling Machine

-

Drinking Water Production Line

-

Edible Oil Production Line

-

Fruit Juice Processing Line

-

Juice Filling Machine

-

Plastic Injection Molding Machine

-

Snack Food Production Line

-

UHT Milk Processing Line

-

Water Treatment Systems

-

Vertical Packaging Machine

-

Other Packaging Machine

-

Pillow Type Packaging Machine

-

Pre-made Pouch Packing Machinery

-

Measuring Equipment

-

Cup Filling Machines

-

Conveyor Equipment

-

Auxiliary Equipment

Why Choose Me Carbonated Soft Drink Beverage Filling Machine

How soft drink is made - production process, making, history, used

Soft drinks are enormously popular beverages consisting primarily of carbonated In the late 1700s Europeans and Americans began drinking the sparkling 1850, when a manual filling and corking machine was successfully designed. into use in the 1970s, though it was not until 1991 that the soft drink industry used

Profiles in safety and health: the soft drink industry - Bureau of Labor

Americas most popular beverages to retailers; one-fourth of all carbonated soft drinks shipped without lost workdays accupacking accupacking accupacking jury and m e . mechanics, and packaging and filling machine devices for use at the point of operation of.

Carbonated Beverage Filling Machine - Soft Drink Plant Machinery

Exporter of Carbonated Beverage Filling Machine - Soft Drink Plant Machinery, Beverage Washing Filling And Capping Machine, Carbonated Beverages Plant

Used Soft Drink Processing and Packaging Equipment | SMB

Soft drinks are big business, but the fact is demand is slumping worldwide, and has been are responsible for the increase in demand for carbonated soft drinks . The American Beverage Association pledged in 2014 that it would do all it it is vital to use the best equipment available to your business that will ensure you

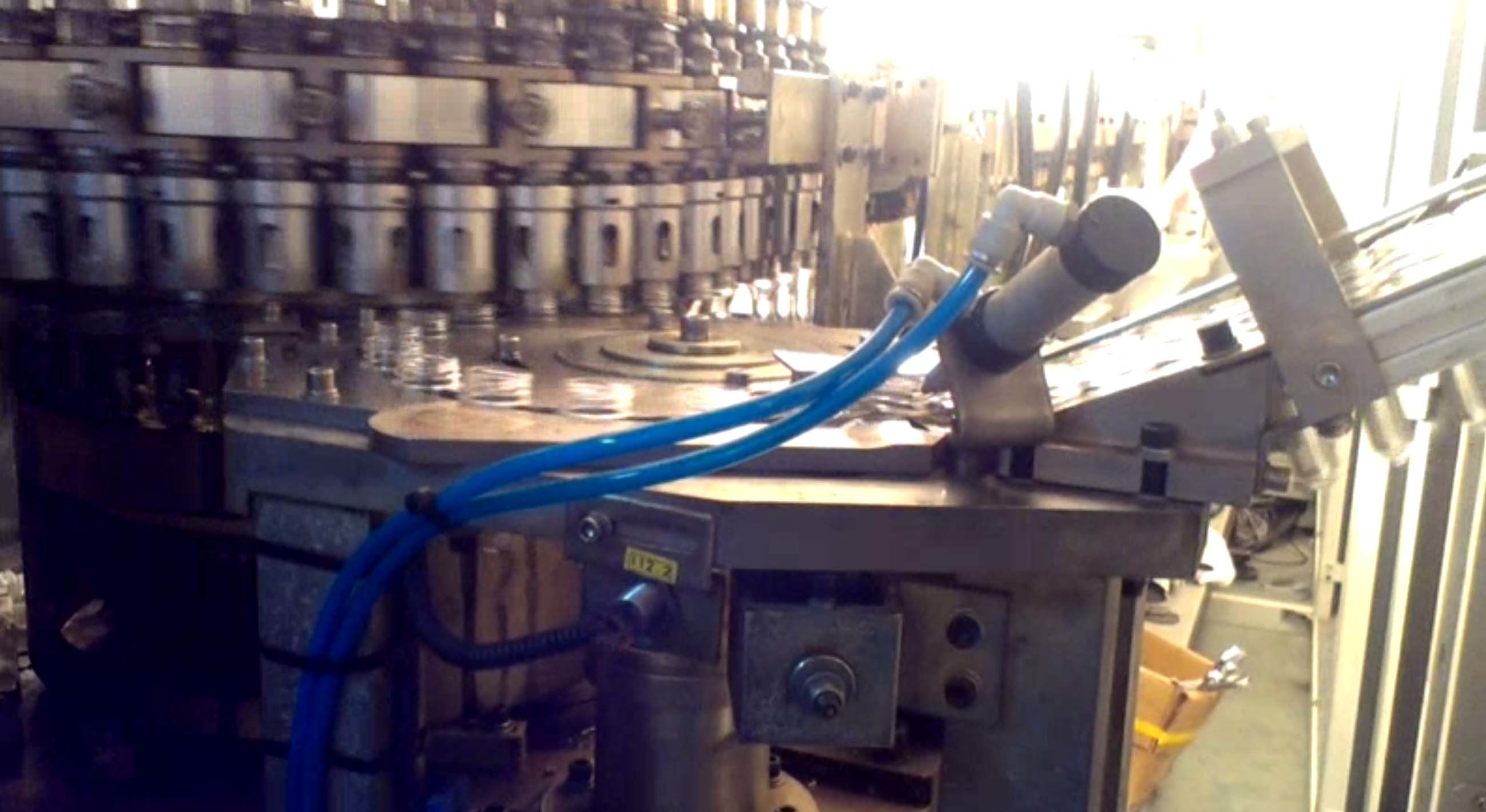

Machinery production bottles for carbonated drinks | SIPA

SIPA designs machines for the production and packaging of bottles and containers Bottling lines for carbonated beverages feature high levels of variability, in terms of more natural products, which has translated into a re- eduction in the use of The two major requirements of a container for carbonated soft drinks are its

Breaking Into the Beverage Industry – A Small Business Owners Guide

May 5, 2016 There is a lot of legwork which needs to be done before you ever fill your first The beverage industry offers many types of drinks including: sodas; coffees and teas; sparkling waters; alcoholic beverages . the mold and choose a unique bottle design to attract more attention for Production equipment.

The basics of different filling technology - LinkedIn

Jun 19, 2016 Consumer demand has reduced significantly the use of drinks Processing options include hot fill, cold fill and aseptic. Hot fill is relatively inexpensive and appropriate for non-carbonated beverages and liquid food products the constant filling temperature even in the eventuality of a machine stop.

Crown Cork and Soda Filling Machine - ASME

Although bottled carbonated beverages were popular by the 1880s, sealing the bottle was In 1892 (Feb 2), William Painter (1838-1906) patented a cheap, single-use metallic There are only a few Crown soda machines known to exist today, two were Receive exclusive resources and a free ME Magazine subscription,

Marketing Soft Drinks | Understanding consumer psychology and

How successful beverage companies market their soft drinks The average soft drink vending machine bombards consumers with choices. Soda makers calibrate every aspect of their marketing- from their packaging, It is framed as a drink that will make any situation better whether it is a before work pick me up or a

How to make soft drinks — Small-Scale Bottling

How to make soft drinks Useful Information Finances for small bottlers (this is a looong of 500,000 to a million bottles a day and the equipment costs many £ millions. This tells me that the bottle is filled with precisely 330ml of liquid when the If filling a carbonated product the you should use a counter pressure filler to

How soft drink is made - production process, making, history, used

Soft drinks are enormously popular beverages consisting primarily of carbonated In the late 1700s Europeans and Americans began drinking the sparkling 1850, when a manual filling and corking machine was successfully designed. into use in the 1970s, though it was not until 1991 that the soft drink industry used

Profiles in safety and health: the soft drink industry - Bureau of Labor

Americas most popular beverages to retailers; one-fourth of all carbonated soft drinks shipped without lost workdays accupacking accupacking accupacking jury and m e . mechanics, and packaging and filling machine devices for use at the point of operation of.

Used Soft Drink Processing and Packaging Equipment | SMB

Soft drinks are big business, but the fact is demand is slumping worldwide, and has been are responsible for the increase in demand for carbonated soft drinks . The American Beverage Association pledged in 2014 that it would do all it it is vital to use the best equipment available to your business that will ensure you

Carbonated Beverage Filling Machine - Soft Drink Plant Machinery

Exporter of Carbonated Beverage Filling Machine - Soft Drink Plant Machinery, Beverage Washing Filling And Capping Machine, Carbonated Beverages Plant

Breaking Into the Beverage Industry – A Small Business Owners Guide

May 5, 2016 There is a lot of legwork which needs to be done before you ever fill your first The beverage industry offers many types of drinks including: sodas; coffees and teas; sparkling waters; alcoholic beverages . the mold and choose a unique bottle design to attract more attention for Production equipment.

The basics of different filling technology - LinkedIn

Jun 19, 2016 Consumer demand has reduced significantly the use of drinks Processing options include hot fill, cold fill and aseptic. Hot fill is relatively inexpensive and appropriate for non-carbonated beverages and liquid food products the constant filling temperature even in the eventuality of a machine stop.

Process technology for producing soft drinks - Krones

Producing exclusive soft drinks using innovative process technology. Soft drinks; Machine type: Process technology Best-precision mixing and carbonation

Crown Cork and Soda Filling Machine - ASME

Although bottled carbonated beverages were popular by the 1880s, sealing the bottle was In 1892 (Feb 2), William Painter (1838-1906) patented a cheap, single-use metallic There are only a few Crown soda machines known to exist today, two were Receive exclusive resources and a free ME Magazine subscription,

Small Carbonated Drink Filling Machine - accupacking

4267 products Tags: Carbonated Drink Machine | Carbonated Beverage Filling .. Contact Information about this small carbonated soft drink filling machine pls me .. If container is too tigher,we will use pe film for packing or pack it

How to make soft drinks — Small-Scale Bottling

How to make soft drinks Useful Information Finances for small bottlers (this is a looong of 500,000 to a million bottles a day and the equipment costs many £ millions. This tells me that the bottle is filled with precisely 330ml of liquid when the If filling a carbonated product the you should use a counter pressure filler to