Live Chat

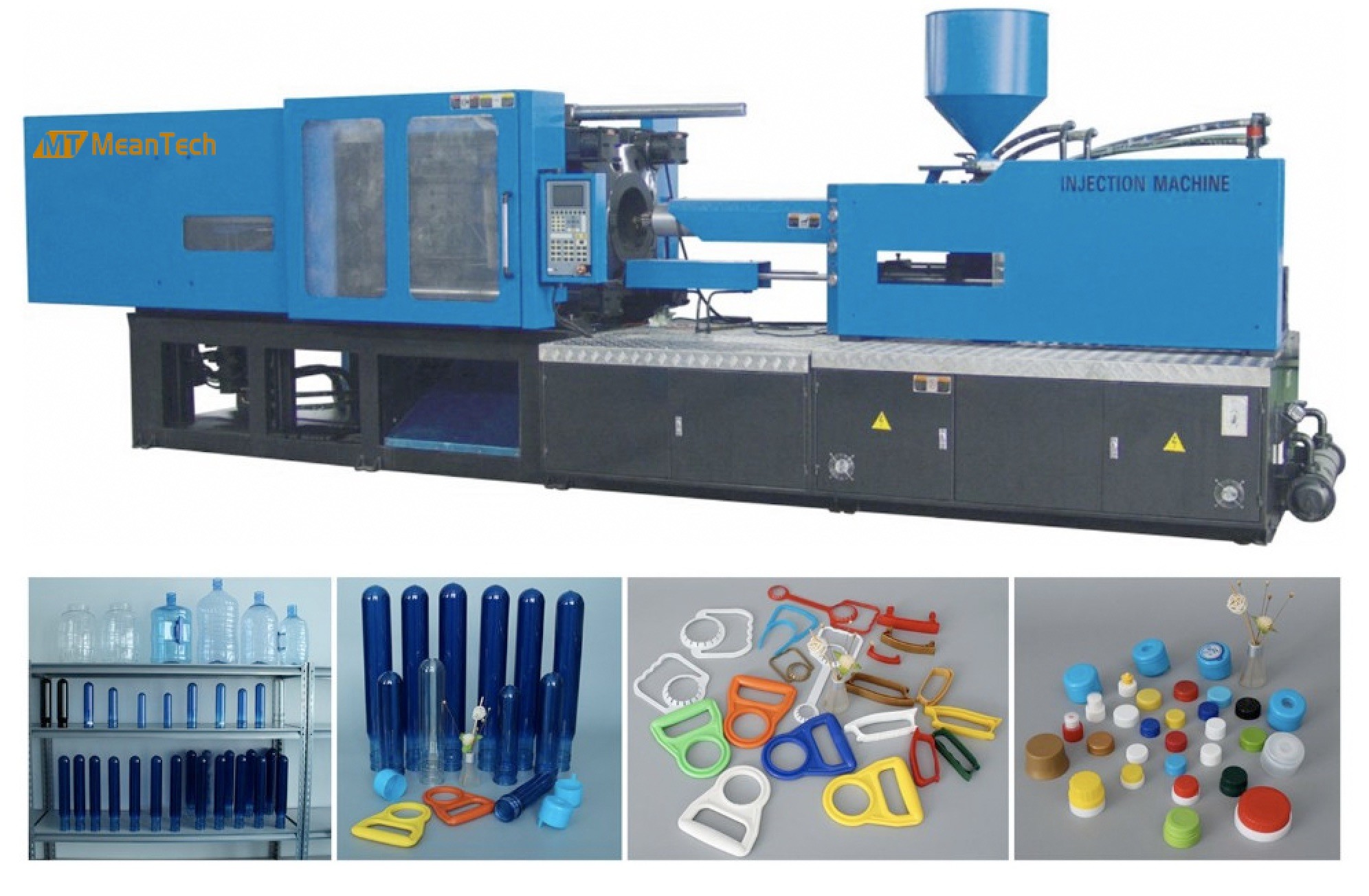

Click the button160T – 1000T Plastic Injection Molding Machine Automatic / Semi Automatic

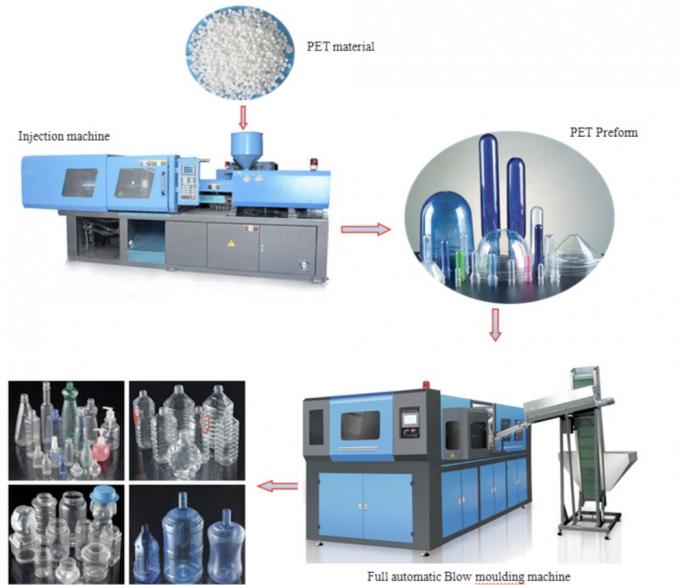

Plastic injection molding Machine for plastic PET Bottle Preform / Cup is widely used for producing all kinds of plastic products including pet bottle preform,plastic cup ,and other plastic products ,for differnt products, you only need to change the mold .

Products

-

Bag Filling Machine

-

Beverage Filling Line

-

Biscuit Making Machine

-

Biscuit Production Line

-

Bottle Blowing Machine

-

Carbonated Drink Production Line

-

Cosmetic Filling Machine

-

Drink Production Line

-

Drinking Water Filling Machine

-

Drinking Water Production Line

-

Edible Oil Production Line

-

Fruit Juice Processing Line

-

Juice Filling Machine

-

Plastic Injection Molding Machine

-

Snack Food Production Line

-

UHT Milk Processing Line

-

Water Treatment Systems

-

Vertical Packaging Machine

-

Other Packaging Machine

-

Pillow Type Packaging Machine

-

Pre-made Pouch Packing Machinery

-

Measuring Equipment

-

Cup Filling Machines

-

Conveyor Equipment

-

Auxiliary Equipment

| Name: | PET Stretch Blow Molding Machine | Type: | Preform Injection |

|---|---|---|---|

| Style: | Horizontal | Brand Name: | Mentech |

| Model Number: | MT-I3234 | Place Of Origin: | Shanghai, China (Mainland) |

| Plastic Type: | Thermoplastic | Automatic: | Yes |

| Injection Weight: | 3715g–6280g |

Automatic / Semi-Automatic 160T-1000T Plastic injection molding Machine for plastic PET Bottle Preform / Cup

Product Descriptions

Plastic injection molding Machine for plastic PET Bottle Preform / Cup is widely used for producing all kinds of plastic products including pet bottle preform,plastic cup ,and other plastic products ,for differnt products, you only need to change the mold .

Product Advantage

- 32 point input, output, interpolation and fault points can be easily replaced.

- water cooling, saving system conditions, preventing high pressure uploading, no power output, saving water cooling.

- The high precision control servo system can precisely control the pressure, speed and position of the machine, and ensure that the precision measurement accuracy error is less than 0.3%.

- the resolution of LIDER transducer is 1/65535, and the control precision is higher.

- The resolution is 800 x 600 display, user-friendly screen and optional language selection.

- the total efficiency of energy saving is over 10%, and the driving capacity is 18% higher than that of the common machine. This series can save 40%-80% energy, achieve the first – class energy – saving effect.

- equipped with USB (2) port and Ethernet (100 base T) port.

- with dual CPU control, the system HMI is displayed with X86 300 MHz technology level. The system adopts RISC 140MHz micro professor, which has high speed, anti-noise, no fan, low power consumption, independent control structure, and improves the stability of control.

Specifications

| ITEM | UNIT | MT-I3234 | |||

| Injection Unit | Screw Diameter | mm | 50 | 52 | 55 |

| Injection Volume | cm3 | 441 | 477 | 534 | |

| Shot Weight | g | 402 | 434 | 486 | |

| Injection Pressure | Mpa | 204 | 189 | 169 | |

| Clamping Unit | Clamping Force | KN | 2400 | ||

| Opening Stroke | mm | 480 | |||

| Mould Thickness(Min-Max) | mm | 220-500 | |||

| Space Between Tie-Bars | mm | 520×520 | |||

| Ejector Force | KN | 70 | |||

| Ejector Stroke | mm | 150 | |||

| General | Motor Power | KW | 22 | ||

| Heater | KW | 14.3 | |||

| Pump Pressure | Mpa | 16 | |||

| Machine Dimension | m | 5.6×1.5×2.2 | |||

| Machine Weight | T | 7 | |||

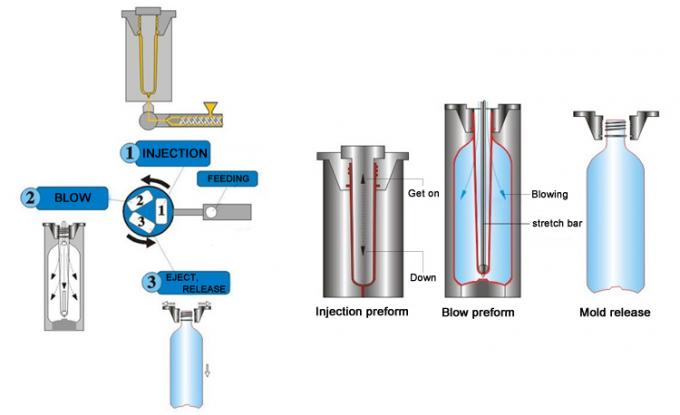

Flow Chart

Complete ling for production bottle

Injection unit

- Quick response checking valve

- Dual alloy 39CrMoAl screw and barrel

- High response and double cylinder injection system with automatic conversion function

- Screw back pressure control

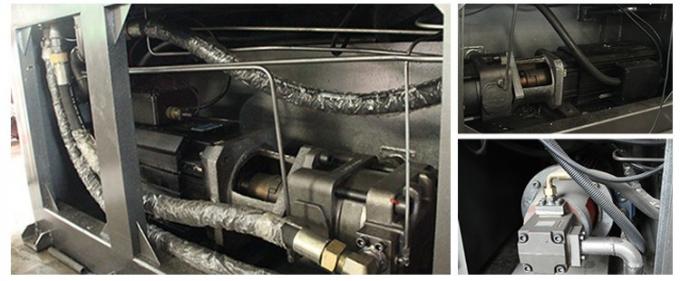

Hydraulic unit

- Top brands hydraulic parts ensure machine fast and stable

- Visible and dischargeable oil tank, easy for hydraulic circuit maintenance

- Top brand hydraulic pipe fits with seal, no leaking

- High response hydraulic circuit,0.05S to reach the maximum power output

Electric Unit

- Top brands electric parts supporting

- High class color screen controller

- Three color tower light with alarm

- Euro standard safety standard

Our services

- The production process is under strict supervision, adopting China and the world's most advanced production technology.

- After the expiration of the warranty period, the service shall be provided for life.

- Each machine is made by experienced staff.

- The warranty period is 2 year. The easy damage spares are excluded.

-

2000BPH – 10000BPH PET Preform Injection Molding Machine For Bottle Preform / Bottle Cap

2000BPH – 10000BPH PET Preform Injection Molding Machine For Bottle Preform / Bottle Cap

The PET preformed injection molding machine from our company...

→ -

Multifunctional Plastic Injection Molding Machine 60T – 4000T Capacity

Multifunctional Plastic Injection Molding Machine 60T – 4000T Capacity

Our plastic Injection molding machine is able to produce all...

→ -

170 Ton Automatic Plastic Injection Moulding Machine Horizontal Style Preform Injection

170 Ton Automatic Plastic Injection Moulding Machine Horizontal Style Preform Injection

Applicable to PP, PE, PET, PC, PS, PVC, ABS, SAN and other t...

→ -

Industrial 1000 Ton Plastic Injection Molding Machine For PET Bottle Preform Making

Industrial 1000 Ton Plastic Injection Molding Machine For PET Bottle Preform Making

High efficiency energy-saving injection molding machine adop...

→