Live Chat

Click the button9 Cavities PET Bottle Blow Molding Machine 6000-25000 Bottle / Hour Linear High Capacity

The automatic bottle blowing machine series is the fastest linear bottle blowing machine in the market, it is separated by baking and blowing/drawing platform, which improves the speed and output of bottle blowing, it is fully controlled by PLC system, it adopts high-pressure air to preform PET bottles from the billet. Awe can help design and blow the bottle according to customers need.

Products

-

Bag Filling Machine

-

Beverage Filling Line

-

Biscuit Making Machine

-

Biscuit Production Line

-

Bottle Blowing Machine

-

Carbonated Drink Production Line

-

Cosmetic Filling Machine

-

Drink Production Line

-

Drinking Water Filling Machine

-

Drinking Water Production Line

-

Edible Oil Production Line

-

Fruit Juice Processing Line

-

Juice Filling Machine

-

Plastic Injection Molding Machine

-

Snack Food Production Line

-

UHT Milk Processing Line

-

Water Treatment Systems

-

Vertical Packaging Machine

-

Other Packaging Machine

-

Pillow Type Packaging Machine

-

Pre-made Pouch Packing Machinery

-

Measuring Equipment

-

Cup Filling Machines

-

Conveyor Equipment

-

Auxiliary Equipment

| Condition: | New | Application: | Bottle |

|---|---|---|---|

| Plastic Processed: | PET | Voltage: | 380V 3phase 50HZ |

| Power(W): | 110kw For Whole System | After-sales Service Provided: | Engineers Available To Service Machinery Overseas |

| Processing Type: | Bottle Blow Molding Machine |

9 Cavities PET Bottle Blow Molding Machine 6000-25000 Bottle / Hour Linear High Capacity

Product Description

The automatic bottle blowing machine series is the fastest linear bottle blowing machine in the market, it is separated by baking and blowing/drawing platform, which improves the speed and output of bottle blowing, it is fully controlled by PLC system, it adopts high-pressure air to preform PET bottles from the billet. Awe can help design and blow the bottle according to customers need.

Product Features

- Prefabricated parts transfer controller: servo motor country (Japan)

- Safe, reliable and unique valve position design makes the pressure diagram of the machine easier to understand.

- No pollution: closed production area, good self-lubricating system, avoid pollution.

- PLC & Touch Screenc display: Siemens (Germany)

- .Automatic transmission of precast blank by conveyer.

- .High clamping force and high pressure crank connecting rod lock mode.

- Low consumption of electricity, air and water.

- It mainly adopts FESTO servo motor and electric positioning system German brand application in bottle billet transportation.

- By adjusting the length of the reflector of the light tube and the preheating zone, the preheater is preheated and the permanent temperature in the preheater is used.

- High quality: stable infrared heating system blowing and high precision blowing mold closing system to ensure quality.

- Low retention rate: less than 0.2%.

- Low cost, high efficiency, easy to operate, easy to maintain and other characteristics, automatic process flow.

- Two modes of operation: automatic and manual.

- Other electrical components are world famous brands.

- B). Pneumatic part: festo (Germany)

- Advanced PLC stability performance.

- High security and security automatic locking device in each mechanical action, the program will become a fault in a process, a country's security.

- high transparency: easy to maintain, absolute safety, visual inspection, low noise.

- 3. Make the bottle permeable and good heat resistant and swift distribution of strong rotation and rotation of the orbit at the same time in the infrared preheater.

- . Non-polluting and low-noise cylinders drive action, not pumps.

- High speed: 6000bph (6 lumen), 8000bph (8 cavities), 12000bph (12 cavities), 16000bph (16 cavities).

- Ideal effect of cooling system cooling.

- High intelligence: the machine can be controlled by the touch screen and the running state is displayed on the screen.

- Easy to install and start.

Specification:

| Model | Unit | MT-2 | MT-4 | MT-6 | MT-8 |

| Capacity | BPH | 2000-2500 | 3000-4000 | 8000-12000 | 12000-25000 |

| Max Volume | L | 2.0 | 2.0 | 2.0 | 0.6 |

| Max Bottle Diameter | mm | 105 | 105 | 105 | 105 |

| Max Bottle Height | mm | 300 | 300 | 300 | 300 |

| Max Stretch Distance | mm | 260 | 260 | 260 | 260 |

| Cavity Qty | Cav. | 2 | 4 | 6 | 8 |

| Heating Power | KW | 48 | 63 | 90 | 125 |

| Use Power | KW | 16 | 24 | 36 | 48 |

| Working Pressure | Mpa | 0.8 | 0.8 | 0.8 | 0.8 |

| Blowing Pressure | Mpa | 3.5 | 3.5 | 3.5 | 3.5 |

| Machine Dimension | m | 2.6*1.7*2 | 3.6*1.7*2 | 4.6*2*2 | 5.2*2.2*2 |

| Weight | T | 2 | 3.2 | 4.2 | 4.8 |

we have many choice for bottle blowing machineare able to customize the machine according to your demands.

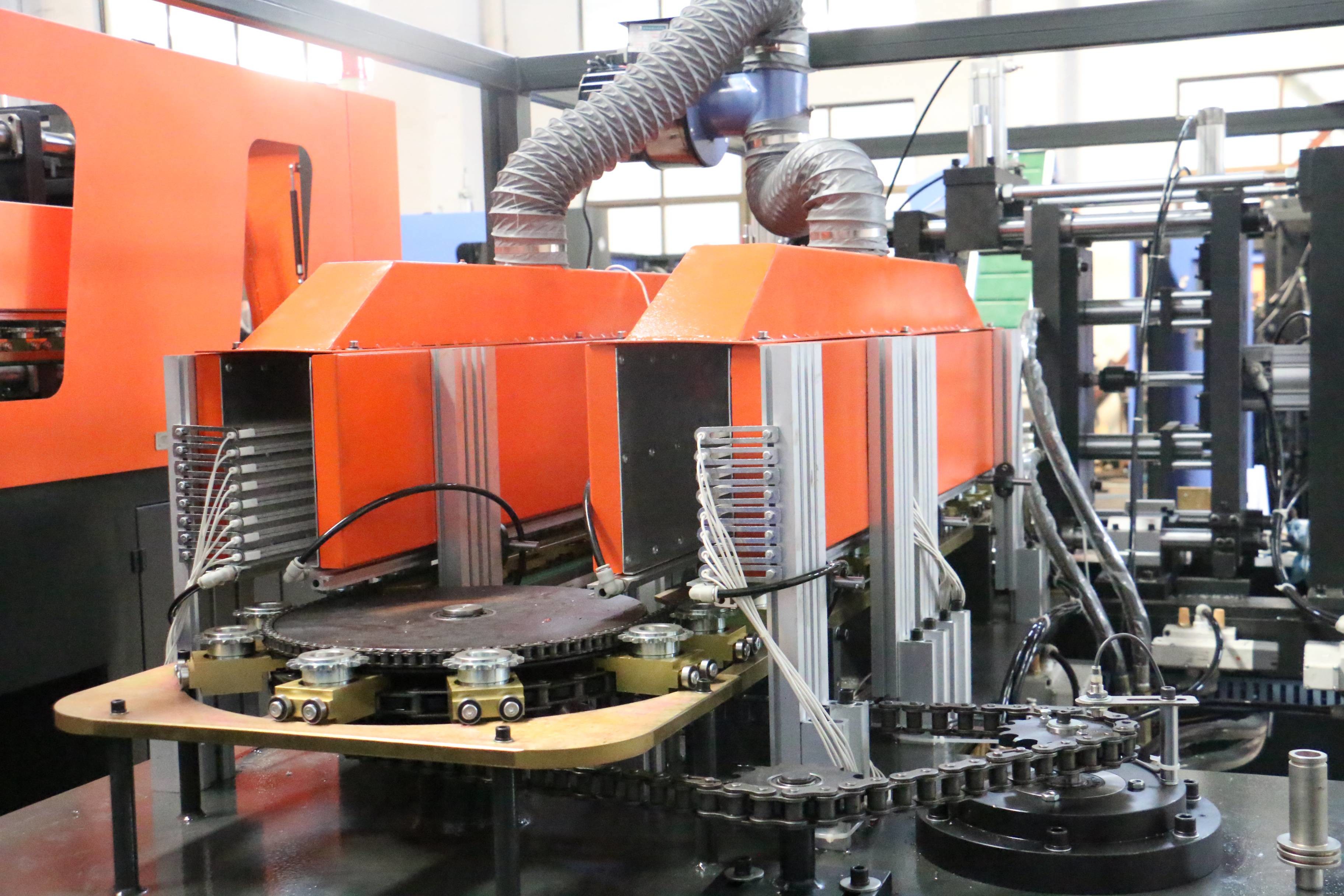

Product Show:

Output Product

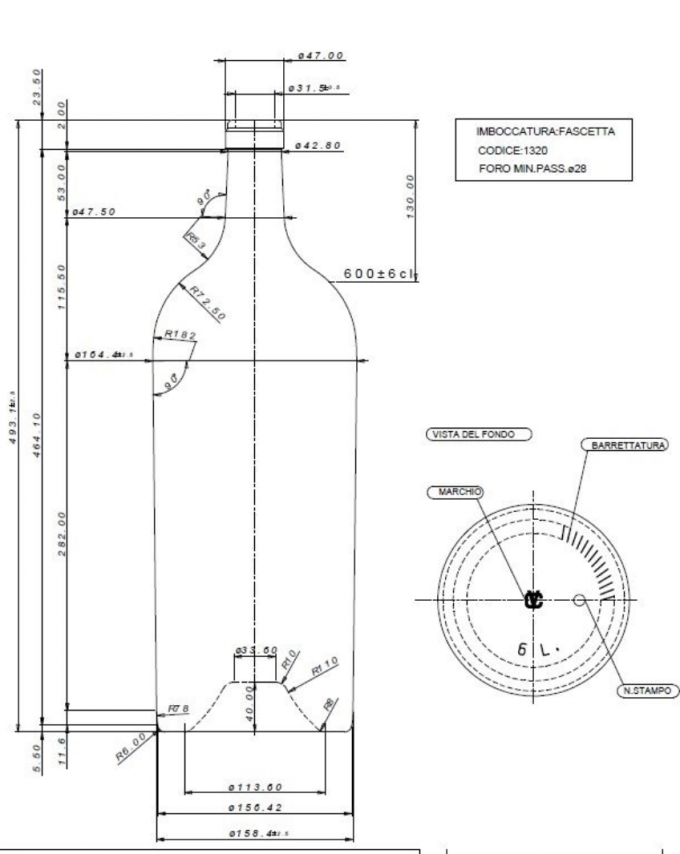

Bottle Design

High quality mold:

Flow Chart

Our Service

- We can provide internship services to help you train operators and mechanics.

- Reply to your email and reply to you in 24 hours and start offering solutions to your problems.

- We can help you design production lines, workshops and provide turnkey projects.

- We will be responsible for the 100% quality inspection before shipment, commissioning the machine to ensure that the machine can be used in accordance with the customer's requirements.

- We will be responsible for instilling technical training in the user so that they can understand the characteristics of the machine and operate the machine on its own.

- Every three years, we can help overhaul the machine (labor);

- The warranty period of our machine is one year, and it is maintained for life. If the customer requires special quality assurance, the other warranty period may be agreed upon by both parties.

-

Fully Automatic Pet Bottle Blowing Machine / 2500 ML 5 Gallon Bottle Blow Molding Machine

Fully Automatic Pet Bottle Blowing Machine / 2500 ML 5 Gallon Bottle Blow Molding Machine

This 5 gallon bottle blow molding machine is widely used for...

→ -

6000 BPH Water Bottle Blowing Machine / Automatic Stretch Blow Moulding Machine

6000 BPH Water Bottle Blowing Machine / Automatic Stretch Blow Moulding Machine

this bottle blowing machine is widely used for bottle blowin...

→ -

5 Gallon Plastic Bottle Blow Molding Machine 7-30L For Beer Bottle / Jar Bottle

5 Gallon Plastic Bottle Blow Molding Machine 7-30L For Beer Bottle / Jar Bottle

Semi-automatic 5 gallons bottles 5 l - 30 l blow molding mac...

→ -

Mineral Water Bottle Blowing Machine Semi Automatic 500 BPH-1000 BPH 350ml / 500ml / 1L

Mineral Water Bottle Blowing Machine Semi Automatic 500 BPH-1000 BPH 350ml / 500ml / 1L

Advanced function and economic investment for bottle making ...

→