Live Chat

Click the buttonAir Flow Puffing Machine , Nuts Filled Biscuit Production Plant For Round Ball

1.largest capacity in air flow puffing machine.

2.Suitable for the puffing process for all kinds of raw material including soy bean, grain, corn, millet, wheat and etc.

3.This machine has the characteristic of large capacity

Products

-

Bag Filling Machine

-

Beverage Filling Line

-

Biscuit Making Machine

-

Biscuit Production Line

-

Bottle Blowing Machine

-

Carbonated Drink Production Line

-

Cosmetic Filling Machine

-

Drink Production Line

-

Drinking Water Filling Machine

-

Drinking Water Production Line

-

Edible Oil Production Line

-

Fruit Juice Processing Line

-

Juice Filling Machine

-

Plastic Injection Molding Machine

-

Snack Food Production Line

-

UHT Milk Processing Line

-

Water Treatment Systems

-

Vertical Packaging Machine

-

Other Packaging Machine

-

Pillow Type Packaging Machine

-

Pre-made Pouch Packing Machinery

-

Measuring Equipment

-

Cup Filling Machines

-

Conveyor Equipment

-

Auxiliary Equipment

Automatic RO Water Treatment Plant , Stainless Steel Water Treatment Equipment

Litchi / Pulp Juice Filling Machine High Capacity Semi- Automatic CE Certificate

High Capacity Carbonated Drink Production Line Machine For 500ml-2500ml Bottle

3 In 1 Plastic Bottle Beverage Filling Machine , Automatic Soft Drink Filling Machine

Red Bull Energy Drink Production Line Automatic For Glass / PET Bottle

Fully Automatic Drinking Water Filling Machine 600-3000BPH For 5 Gallon PET Bottle

Bottled Mineral Drinking Water Production Machine / Filling Production Line

SUS304 PET Bottle Edible Oil Bottle Filling Machine For Non Viscous Liquid Filling

| Condition: | New | Place Of Origin: | Shanghai, China (Mainland) |

|---|---|---|---|

| Brand Name: | Qualipak | Model Number: | MT-4343 |

| Application: | Biscuit , Candy | Voltage: | 380V |

| Power(W): | 2kw | Weight: | 800kg |

| Dimension(L*W*H): | 3500*1200*800mm | Capacity: | 150-180kg/h |

| Usage: | Cereal Foming | Technology: | Multifunctional Cereal Forming |

| Machine Name: | Cereal Bar Forming Machine | Product: | Rice Bar,wheat Bar,candy And So On |

| Product Shape: | Round Ball,round Cake,round Bar,bar,cube,pie Etc | Applied Object: | Cereal/peanut /sumelon Seeds /sesame /maize Sugar Or Chocolate Etc |

| Blanking Ways: | Automatic |

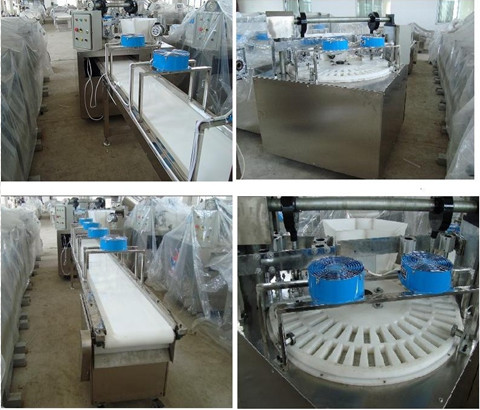

Air Flow Puffing Machine, Nuts Filled Biscuit production line for round ball,round cake,round bar,bar,cube,pie

Brief introduction of the puffed rice cake production line

The rice cake making processing line need six machines: air puffing machine—-candy cooking machine—–mixing machine—-lift conveyor —rice cake forming machine—cooling conveyor

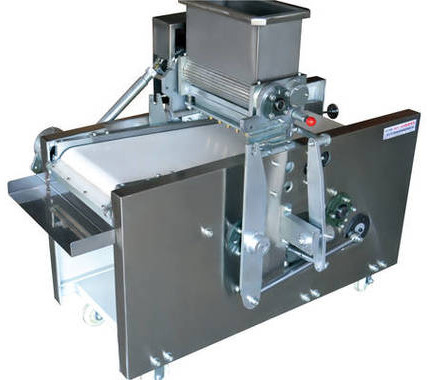

Large-scale Air Flow Puffing Machine

Primary specialized details:

Voltage: 380V

Power: 0.75kw

Capability: 8—10kg

Volume: 60—90kg/h

Weight: 380kg

Size: 1650x800x1350

Short advantages of cereal bar puffing machine

1.largest capacity in air flow puffing machine.

2.Suitable for the puffing process for all kinds of raw material including soy bean, grain, corn, millet, wheat and etc.

3.This machine has the characteristic of large capacity,

4. low energy consumption, higher security factor.

5, high performance, simple and safe operation , only one person is required for operating the whole production line.

6, To maximize the retention of barley, wheat, corn and other coarse grainsof the original flavor, color and nutrition

Candy cooking pot-100L

This equipment is made of stainless steel, and uses electricity, gas, steam, heat transfer oils as heating as power source. It has tilt equipped for discharging mechanism. It is widely used in food cooking food and boiling

Mixing machine

Model: MT-200

The mixer can mix the candy food and so on

Voltage: 380v power 1.1kw

Capacity: 200kg/h

Inner size: 680mm*600mm

Size: 800*900*1400

Weight: 120kg

Conveyor

Size:2.5m x0.56m

Motor: 0.75kw

Capacity: 350kg/h

Cereal bar slicing machine

| Model | MT-68 |

| Capacity | 300kg/h |

| Power | 380v/2.2kw |

| Weight | 850kg |

| Dimension | 6200*1200*1200mm |

Cooling conveyor

Power: 0.75kw

Size: 2500*820*720mm

MT-250B Pillow type packing machine

| Model | DXD-250 |

| Machine speed | 30-200bags/min |

| bag size | Length: 65-190 or120-280mm width: 30-110mm |

| Max Film Width | 250mm |

| Net weight | 500KG |

| Bag type | Pillow type bag |

| Notch | Zipper |

| Voltage | AC220V Single-phase 50HZ or 380V 50HZ three phases |

| Total Power | 3kw |

| Measuring range | 27grams/sachet |

| G.W | 650KG |

| Control system | Panasonic PLC control system |

| Packing material | BOPP/CPP.PET/AL/PE |

| Machine Dimension | 3000*940*1500mm |

Packaging & Shipping

Package :Our cereal bar forming equipment are putted in strong wooden cases.

Delivery time : within 3-15 working days following receiving the down payment

If you need any support fro us,please contact with us: eric@meantech.net

Pre-sale service:

1,Recommend the the best option equipment for customers,especially corresponding to

clients need

2,Strictly control easy production line and easy parts,to ensure machine quality.

3 every machine is tested before delivery,to ensure machine function well.

After-sale service:

1,12 month guarantee

2,lifelong free tech assistance and spare parts support

3,bug solving rapidly

-

Snacks Food Biscuit Production Line For Crisp Biscuit / Tenacity Biscuit

Snacks Food Biscuit Production Line For Crisp Biscuit / Tenacity Biscuit

The biscuit processing line is an professional products for ...

→ -

Multifunctional Biscuit Production Machine , Wafer Biscuit Making Machine

Multifunctional Biscuit Production Machine , Wafer Biscuit Making Machine

Cookies forming equipment makes a variety of types of snack ...

→ -

Cream Filled Wafer Biscuit Production Line Fully Automatic Easy Operation

Cream Filled Wafer Biscuit Production Line Fully Automatic Easy Operation

1.The entire system of the production line is made of 304 St...

→ -

Full Automatic Biscuit Production Line Multifunctional 1000kgs Capacity For Cookie

Full Automatic Biscuit Production Line Multifunctional 1000kgs Capacity For Cookie

Fully automatic to reduce the cost of running. Highly effic...

→