Products

-

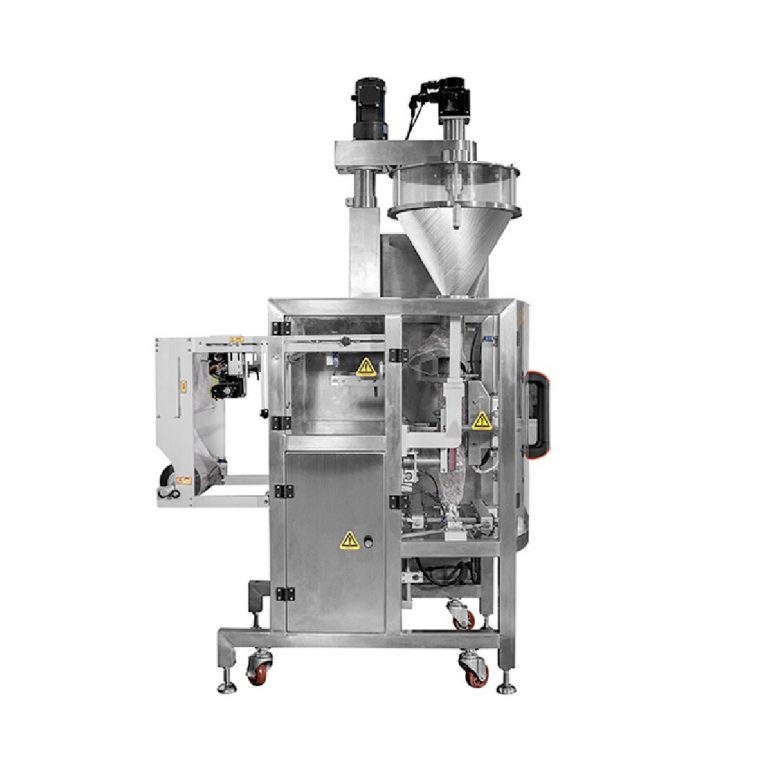

Bag Filling Machine

-

Beverage Filling Line

-

Biscuit Making Machine

-

Biscuit Production Line

-

Bottle Blowing Machine

-

Carbonated Drink Production Line

-

Cosmetic Filling Machine

-

Drink Production Line

-

Drinking Water Filling Machine

-

Drinking Water Production Line

-

Edible Oil Production Line

-

Fruit Juice Processing Line

-

Juice Filling Machine

-

Plastic Injection Molding Machine

-

Snack Food Production Line

-

UHT Milk Processing Line

-

Water Treatment Systems

-

Vertical Packaging Machine

-

Other Packaging Machine

-

Pillow Type Packaging Machine

-

Pre-made Pouch Packing Machinery

-

Measuring Equipment

-

Cup Filling Machines

-

Conveyor Equipment

-

Auxiliary Equipment

Automatic RO Water Treatment Plant , Stainless Steel Water Treatment Equipment

Litchi / Pulp Juice Filling Machine High Capacity Semi- Automatic CE Certificate

High Capacity Carbonated Drink Production Line Machine For 500ml-2500ml Bottle

3 In 1 Plastic Bottle Beverage Filling Machine , Automatic Soft Drink Filling Machine

Red Bull Energy Drink Production Line Automatic For Glass / PET Bottle

Fully Automatic Drinking Water Filling Machine 600-3000BPH For 5 Gallon PET Bottle

Bottled Mineral Drinking Water Production Machine / Filling Production Line

SUS304 PET Bottle Edible Oil Bottle Filling Machine For Non Viscous Liquid Filling

Blow-Fill-Seal Machines For Aseptic Packaging

Sterilization of Blow-Fill-Seal Equipment for Aseptic Filling

Jul 2, 2014 Nitrogen dioxide can sterilize and depyrogenate an aseptic fill area in a blow-fill- seal process.

Blow-fill-seal Technology Advances in Aseptic Filling Applications

Jun 18, 2014 Equipment and Processing Report. In blow-fill-seal (BFS) technology, which is a form of advanced aseptic manufacturing, the container is

blow/fill/seal: an advanced aseptic packaging technology

BLOW-FILL-SEAL: AN ADVANCED. ASEPTIC PACKAGING TECHNOLOGY. SPONSORED BY. 3. Machine Operation. The B/F/S process enables a container to

“BFS” Blow Fill and Seal Technology – Brevetti Angela

Blow Fill and Seal technology is mainly used for pharmaceutical solutions. The filling process can be carried out under a shower of sterile filtered air to avoid trimming the containers and delivering the containers outside the machine.

Blow fill seal - Wikipedia

Blow-Fill-Seal (BFS) technology is a manufacturing technique used to produce small, (accupacking) The mould is transferred to the filling zone, or sterile filling space , where filling needles (mandrels) are lowered and used to inflate the plastic to form All actions take place inside a sterile shrouded chamber inside the machine.

BFS - Engineering - Rommelag

Rommelags bottelpack machines are capable of manufacturing up to 34,000 containers an hour in a wide variety of forms and This makes bottelpack technology the most reliable aseptic filling method. THE BLOW-FILL-SEAL PROCESS

LIQUID SPECIAL BLOW-FILL-SEAL - Rieckermann

Rieckermann blow-fill-seal technology combines forming, sterile/antiseptic filling and closing in one machine. It minimizes contamination and lower production

Blow-fill-seal packaging for pharmaceuticals | Machine Design

Sep 8, 2011 Pharmaceuticals packaged by blow molding, sterile filling, and hermetic sealing, which require minimal operator intervention, are less prone to

Blow / Fill / Seal | Catalent

Catalent offers customized, aseptic packaging for sterile respiratory and ophthalmic that drive the most efficient patient outcomes.

Weiler Engineering, Inc. - ASEP-TECH® Blow/Fill/Seal Machines for

Weiler Engineering is a leading manufacturer of the most advanced aseptic liquid packaging technology available through the application of customized

Sterilization of Blow-Fill-Seal Equipment for Aseptic Filling

Jul 2, 2014 Nitrogen dioxide can sterilize and depyrogenate an aseptic fill area in a blow-fill- seal process.

Blow-fill-seal Technology Advances in Aseptic Filling Applications

Jun 18, 2014 Equipment and Processing Report. In blow-fill-seal (BFS) technology, which is a form of advanced aseptic manufacturing, the container is

blow/fill/seal: an advanced aseptic packaging technology

BLOW-FILL-SEAL: AN ADVANCED. ASEPTIC PACKAGING TECHNOLOGY. SPONSORED BY. 3. Machine Operation. The B/F/S process enables a container to

“BFS” Blow Fill and Seal Technology – Brevetti Angela

Blow Fill and Seal technology is mainly used for pharmaceutical solutions. The filling process can be carried out under a shower of sterile filtered air to avoid trimming the containers and delivering the containers outside the machine.

Blow fill seal - Wikipedia

Blow-Fill-Seal (BFS) technology is a manufacturing technique used to produce small, (accupacking) The mould is transferred to the filling zone, or sterile filling space , where filling needles (mandrels) are lowered and used to inflate the plastic to form All actions take place inside a sterile shrouded chamber inside the machine.

BFS - Engineering - Rommelag

Rommelags bottelpack machines are capable of manufacturing up to 34,000 containers an hour in a wide variety of forms and This makes bottelpack technology the most reliable aseptic filling method. THE BLOW-FILL-SEAL PROCESS

LIQUID SPECIAL BLOW-FILL-SEAL - Rieckermann

Rieckermann blow-fill-seal technology combines forming, sterile/antiseptic filling and closing in one machine. It minimizes contamination and lower production

Blow-fill-seal packaging for pharmaceuticals | Machine Design

Sep 8, 2011 Pharmaceuticals packaged by blow molding, sterile filling, and hermetic sealing, which require minimal operator intervention, are less prone to

Blow / Fill / Seal | Catalent

Catalent offers customized, aseptic packaging for sterile respiratory and ophthalmic that drive the most efficient patient outcomes.

Weiler Engineering, Inc. - ASEP-TECH® Blow/Fill/Seal Machines for

Weiler Engineering is a leading manufacturer of the most advanced aseptic liquid packaging technology available through the application of customized