Live Chat

Click the buttonCommercial Automatic Carbonated Drink Production Line Big Capacity For Coca – Cola

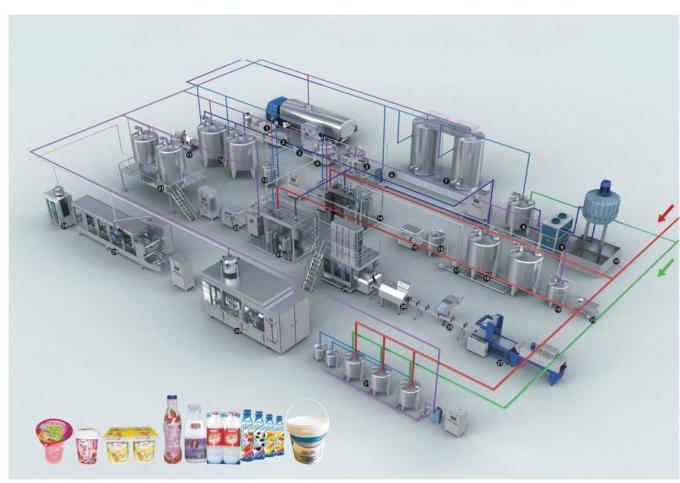

Automatic Carbonated Soft Drinks (CSD) Drink Production Line mainly includes pure water system, high shear sugar pan, batching pot, syrup filter, high power beverage mixer, carbon dioxide filter, cold water machine, CIP cleaning equipment, bottled filling machine, automatic lid machine, thermos bottle machine, blows machine, printer, label equipment and packaging. Equipment.

According to the actual demand of the market, the production line of Bottled bottled beverage production line provided by our company can reach 2000 bottles / 34000 bottles / hours by the 500ml bottle.

Products

-

Bag Filling Machine

-

Beverage Filling Line

-

Biscuit Making Machine

-

Biscuit Production Line

-

Bottle Blowing Machine

-

Carbonated Drink Production Line

-

Cosmetic Filling Machine

-

Drink Production Line

-

Drinking Water Filling Machine

-

Drinking Water Production Line

-

Edible Oil Production Line

-

Fruit Juice Processing Line

-

Juice Filling Machine

-

Plastic Injection Molding Machine

-

Snack Food Production Line

-

UHT Milk Processing Line

-

Water Treatment Systems

-

Vertical Packaging Machine

-

Other Packaging Machine

-

Pillow Type Packaging Machine

-

Pre-made Pouch Packing Machinery

-

Measuring Equipment

-

Cup Filling Machines

-

Conveyor Equipment

-

Auxiliary Equipment

| Type: | Carbonated Soda Filling Machine | Condition: | New |

|---|---|---|---|

| Packaging Material: | Plastic, Wood | Automatic Grade: | Automatic |

| Product Name: | Soft Drink Filling Machine | Degree Of Automation: | Full Auotmatic |

| Processing Types: | Soft Drink, Carbonated Drink | PLC/ Transducer/ Touch Screen: | Siemens |

Factory Price Durable Stable Stainless Steel Automatic Carbonated Soft Drinks (CSD) Drink Production Line

Product Description

Automatic Carbonated Soft Drinks (CSD) Drink Production Line mainly includes pure water system, high shear sugar pan, batching pot, syrup filter, high power beverage mixer, carbon dioxide filter, cold water machine, CIP cleaning equipment, bottled filling machine, automatic lid machine, thermos bottle machine, blows machine, printer, label equipment and packaging. Equipment. According to the actual demand of the market, the production line of Bottled bottled beverage production line provided by our company can reach 2000 bottles / 34000 bottles / hours by the 500ml bottle.

Product Details

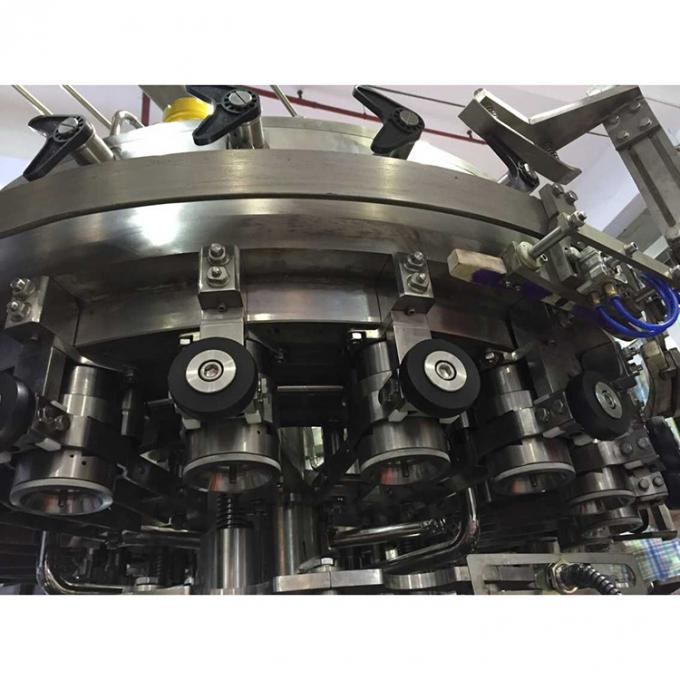

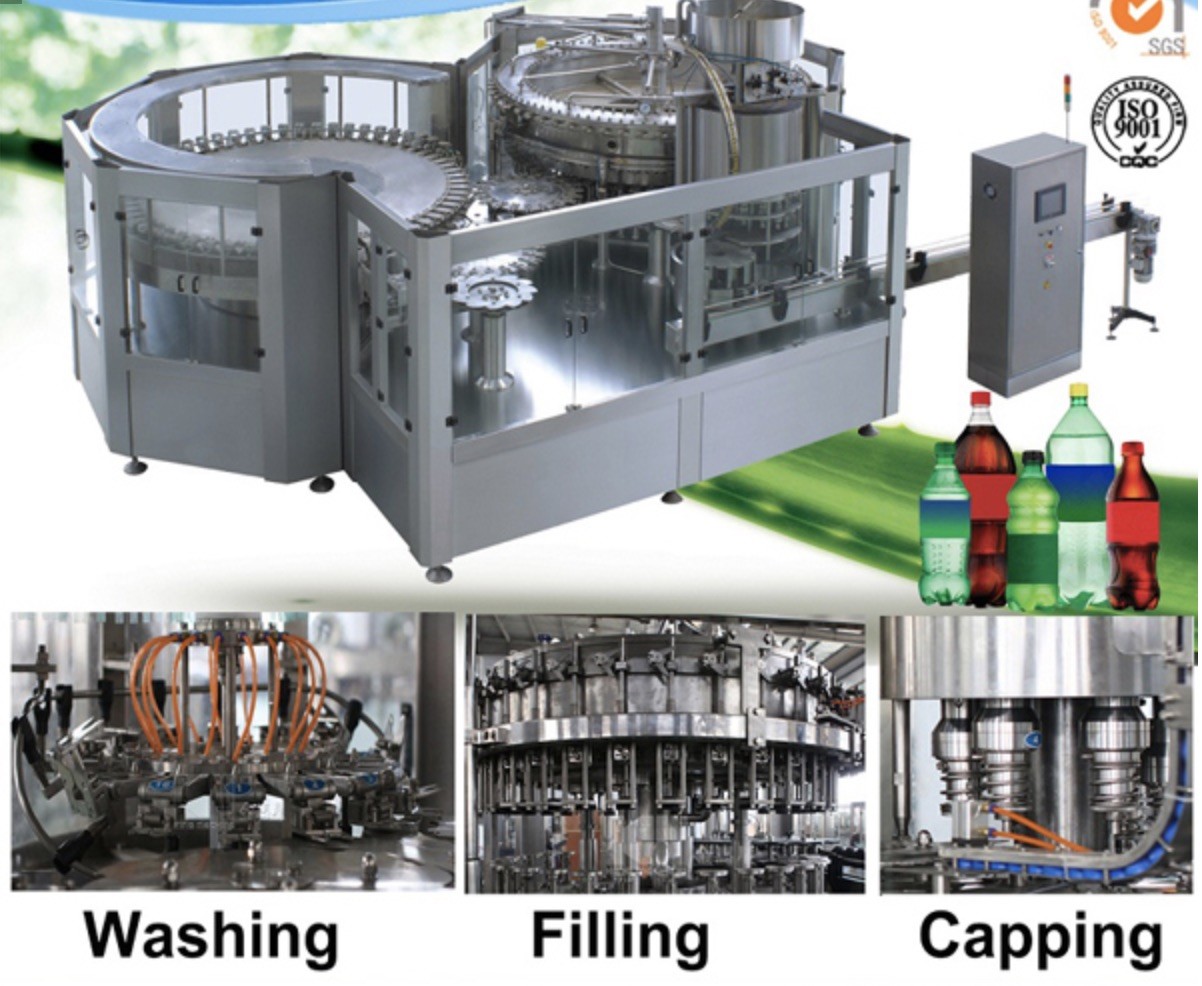

In the automatic gas – containing beverage production equipment, the material mixed with carbon dioxide automatically enters the liquid cylinder of the filling machine of the gas – containing beverage under the pressure difference, and the constant pressure filling principle is used to fill the liquid level. The filling machine of glass bottle containing gas drink is used in the way of feeding chain, that is, under the drive of the motor, the glass bottle enters the three in one filling machine with the air containing beverage in turn. The glass bottles are separated by the screw pitch by the bottle splitting screw, then the star wheel and the bottle bottom device are transferred in the middle, and the glass bottles are transferred to the flushing part, the filling part and the cover part of the glass bottle filling machine. Among them, the contact part of the clamping device and the bottle mouth of the flushing device adopts the engineering food grade pollution-free plastic, so that the bottle mouth of the glass bottle can not be clamped. In case of low local temperature, glass bottle washing water needs preheating, and a flushing water cushion preheating device can be equipped to avoid detonating bottles. The filling machine of plastic bottle containing gas beverage is used in the way of air inlet bottle, that is, the empty bottle mouth is hung on the wind track. Under the wind force provided by the fan, the empty bottle enters the bottled filling equipment in turn. Through the middle star wheel, the bottle is successively through the bottle washing, filling and capping mechanism. The bottle washing procedure: the bottle mouth clamp holds the bottleneck and rotates 360 degrees along the specific burning guide rail to complete the following washing steps:

(1) the glass bottle reverses 180 degrees, the bottle mouth is down to the bottom 2, the valve is automatically opened, and the flushing valve is automatically closed, the flushing bottle in the drained bottle is turned 180 degrees and the bottle mouth is upwards. Then, enter the filling part of the filling machine for gas drink, and use the principle of isobaric filling to fill the beverage containing carbon dioxide gas in the liquid cylinder. The filling process is as follows:

(1) the initial location: the bottle mouth has not yet touched the filling valve, and all the gas and liquid passages are closed.

2. Inflatable back pressure: the bottle and the filling valve cover up to the predetermined position, when the turning fork opens the inflatable valve, and the pressure gas enters the bottle through the inflatable channel from the annular tank. Injection back gas: when the pressure in the bottle reaches the pressure of the tank, the liquid valve opens automatically, and the gas containing liquid needs to be flowing down the wall of the bottle by the split parachute. At the same time, the pressure gas replaced in the bottle returns to the tank through the return pipe, and the liquid is finished when the level of the bottle reaches the lower port of the return pipe. Valve closing: turn the fork to close the pressure gas valve and the liquid valve. Inflation: the top of the carbon dioxide is opened, and carbon dioxide and other inert gases are poured into the bottle from the annular groove, and the air is removed from the bottleneck. The release of pressure: the pressure relief valve opens, the pressure of the bottle through the needle valve in the pressure release channel in the annular groove to escape. Finally, the filling gas filled beverage enters the capping device and completes the sealing process.

A plastic bottle filling machine can be used to fill in a variety of capacity bottles. That is, 350ml, 500ml and 1L can be used as a filling equipment for a gas containing beverage, but it is necessary to ensure the same diameter of the bottle. In the case of a variety of bottles, in order to replace the bottle type, the three in one filling machine is equipped with a falling bottle device. In changing the bottle type, it does not need to adjust the height of the conveyer line, so as to ensure that the bottle is stable and not, only the auxiliary guide wheel under the wheel is replaced. The operation is simple and convenient.

Flow Chart

We are able to supply whole production including :

Water treatment system

– Blow molding machine

– CSD preparation and mixing system

– Bottle unscrambler/Manual bottle loading system

– Air conveyor

– Rinsing-filling-capping 3-in-1 monoblock

– Bottle Warmer

– Labeling Machine

– Water Blow Drier,

– Lampinspection,

– Code ink jetter

– Shrink wrapper / carton packaging machine

– Palletizing system

– Conveying System

Product Sepcifications

-

High precision filling nozzle, PLC variable signal control ensures high filling accuracy and stable filling.

Lifilling volume can be adjusted in the ranking, after the same liquid level filling.

Flling part of bottled mineral water filling machine:

automatic stop when no bottle

All my 304 stainless steel contact parts with liquid tank, fine polishing, no dead Angle, easy to clean. -

304 stainless steel washing head, spray injection design, saving water and cleaning.

-

Cover system, electromagnetic cover, with discharge function to ensure that the minimum bottle is broken during sealing.

-

304 stainless steel washing pump.

stainless steel clamp and plastic cushion to ensure the smallest bottle collision during cleaning.

We could customize the machine according to your need, contact us for more details.

Product Pictures

Our Machine VS others

OutPut Product

Packaging & delivery

Our Service

- Our company can supply turnkey project.

- Our company has a professional design team, our engineers can draw a bottle sample for you and the flow chart of the workshop.

- Provide one year warranty and provide free stock for you in quality guarantee time.

- Provide quotation and business plan in time.

- 1. We send engineers to help with installation, commissioning and training, and engineers start from our factory.

- 2. We provide the following necessary documents and machines:

- A. machine layout

- B. the electrical diagram

- C. computer certificate

- D. general manual/maintenance manual.

- The seller shall provide the spare parts and technical personnel to the home repair service within one year's warranty period.

Contact Us

Send you inquery now!we will make a business proposal for you in 12hours!

-

Automatic DXGF / Coca Cola Production Line , Carbonated Drink Filling Machine

Automatic DXGF / Coca Cola Production Line , Carbonated Drink Filling Machine

The equipment uses PLC as the control system, uses pressure ...

→ -

3 In 1 Automatic Soda Water Filling Machine , Small Carbonated Soft Drink Filling Machine

3 In 1 Automatic Soda Water Filling Machine , Small Carbonated Soft Drink Filling Machine

The carbonated drink filling machine used for prouction of...

→ -

Turnkey Project CSD Carbonated Drink Production Line High Capacity 8000 BPH – 15000 BPH

Turnkey Project CSD Carbonated Drink Production Line High Capacity 8000 BPH – 15000 BPH

Complete CSD carbonated filling line has the 3 function of w...

→ -

High Efficiency Carbonated Drink Production Line Washing Filling And Capping Machine

High Efficiency Carbonated Drink Production Line Washing Filling And Capping Machine

The drinking water filling machine adopts the bottleneck har...

→