Products

-

Bag Filling Machine

-

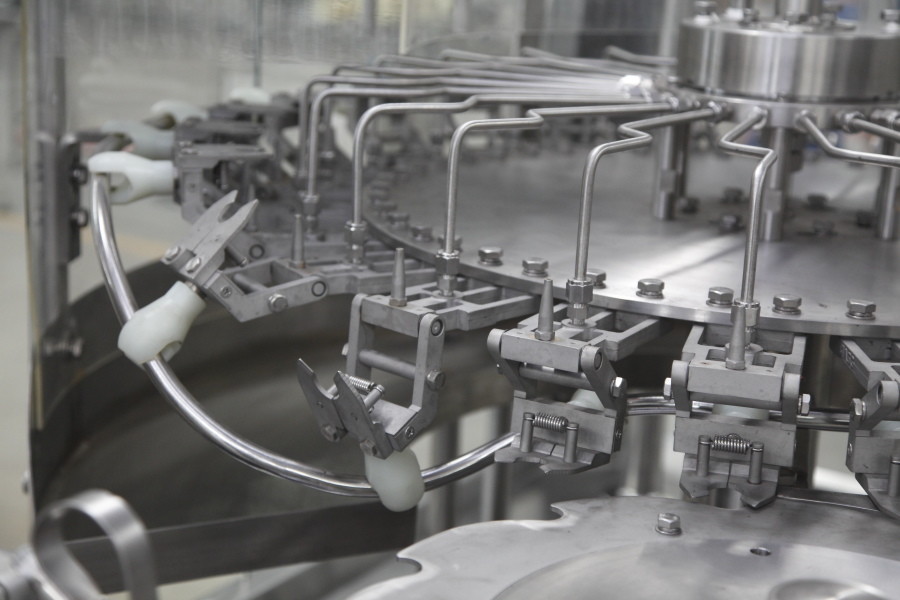

Beverage Filling Line

-

Biscuit Making Machine

-

Biscuit Production Line

-

Bottle Blowing Machine

-

Carbonated Drink Production Line

-

Cosmetic Filling Machine

-

Drink Production Line

-

Drinking Water Filling Machine

-

Drinking Water Production Line

-

Edible Oil Production Line

-

Fruit Juice Processing Line

-

Juice Filling Machine

-

Plastic Injection Molding Machine

-

Snack Food Production Line

-

UHT Milk Processing Line

-

Water Treatment Systems

-

Vertical Packaging Machine

-

Other Packaging Machine

-

Pillow Type Packaging Machine

-

Pre-made Pouch Packing Machinery

-

Measuring Equipment

-

Cup Filling Machines

-

Conveyor Equipment

-

Auxiliary Equipment

Automatic RO Water Treatment Plant , Stainless Steel Water Treatment Equipment

Litchi / Pulp Juice Filling Machine High Capacity Semi- Automatic CE Certificate

High Capacity Carbonated Drink Production Line Machine For 500ml-2500ml Bottle

3 In 1 Plastic Bottle Beverage Filling Machine , Automatic Soft Drink Filling Machine

Red Bull Energy Drink Production Line Automatic For Glass / PET Bottle

Fully Automatic Drinking Water Filling Machine 600-3000BPH For 5 Gallon PET Bottle

Bottled Mineral Drinking Water Production Machine / Filling Production Line

SUS304 PET Bottle Edible Oil Bottle Filling Machine For Non Viscous Liquid Filling

Dgf80-80-18 Carbonated Soft Drinks Production Line /Sparkling Water Filling Machine

A Guide to the soft drink industry - ChangeLab Solutions

and sales. the report covers the main product lines of the industry: carbonated soft drinks, fruit beverages, bottled water, so-called functional beverages ( including . related products for use in soda fountains or for manufacturing soft accupacking . this accupacking interest in approximately 80 bottling plants. the companys contract.

Bottled Carbonated Water Production Plant - YouTube

Jul 23, 2014 http://accupacking/carbonated-drink-bottling-line/ Carbonated drink filling production and bottling line is mainly suitable for

Carbonated Soft Drink Filling Line, Soda Bottling Machine, CSD

Oct 6, 2012 Carbonated Soft Drink Filling Line, Soda Bottling Machine, CSD Filling Water Treatment System, Syrup Processing Systems, Carbonation

carbonated drinks filling line filling capping packaging production

Apr 12, 2014 Carbonated Drink Filling Machine for sparkling beverage bottle washing filling capping. This Small Bottle Carbonated Drink Coca Cola Filling

Machinery production bottles for carbonated drinks | SIPA

SIPA designs machines for the production and packaging of bottles and containers Bottling lines for carbonated beverages feature high levels of variability, in terms of It is very important to optimise the manufacturing process of a CSD bottle The two major requirements of a container for carbonated soft drinks are its