Live Chat

Click the buttonLess Energy Pet Bottle Blowing Machine , 80 Ton PET Preform Molding Machine

The equipment is adopted The special PET screw can significantly improve the plasticizing speed and pellet weight, reduce the plasticizing speed and display weight, reduce the plasticizing temperature, reduce the shear performance, and achieve better transparency.· the servo motor control system is 30% ~ 50% energy saving, and the variable pump control system energy saving is 25% ~ 45%.· our company has different models for different production and bottle shape, which can be used by customers.

Products

-

Bag Filling Machine

-

Beverage Filling Line

-

Biscuit Making Machine

-

Biscuit Production Line

-

Bottle Blowing Machine

-

Carbonated Drink Production Line

-

Cosmetic Filling Machine

-

Drink Production Line

-

Drinking Water Filling Machine

-

Drinking Water Production Line

-

Edible Oil Production Line

-

Fruit Juice Processing Line

-

Juice Filling Machine

-

Plastic Injection Molding Machine

-

Snack Food Production Line

-

UHT Milk Processing Line

-

Water Treatment Systems

-

Vertical Packaging Machine

-

Other Packaging Machine

-

Pillow Type Packaging Machine

-

Pre-made Pouch Packing Machinery

-

Measuring Equipment

-

Cup Filling Machines

-

Conveyor Equipment

-

Auxiliary Equipment

| Product: | PET Bottle Blow Molding Machine | Material: | Stainless Steel 304 Or 316L |

|---|---|---|---|

| Applications: | PET,PP, PE, PET, PC, PS, PVC, ABS, SAN | Warranty: | 2 Year |

| Service: | Oversea Installation,debugging,training | Payment Term: | TT/LC |

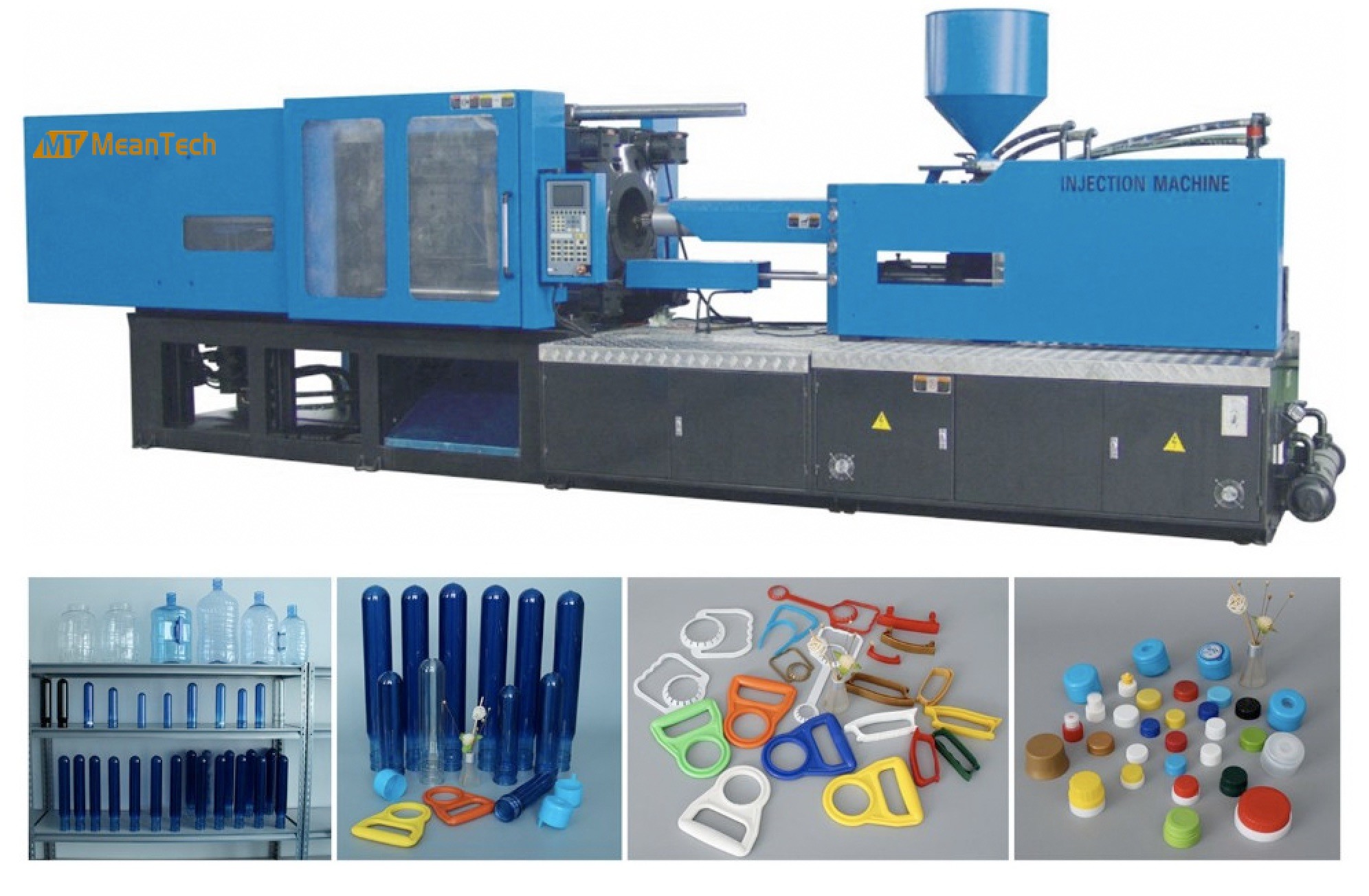

CE Certificate Pet Bottle Preform Plastic Injection Machine 80 Ton Less Energy For PP, PE, PET

Product Descriptions

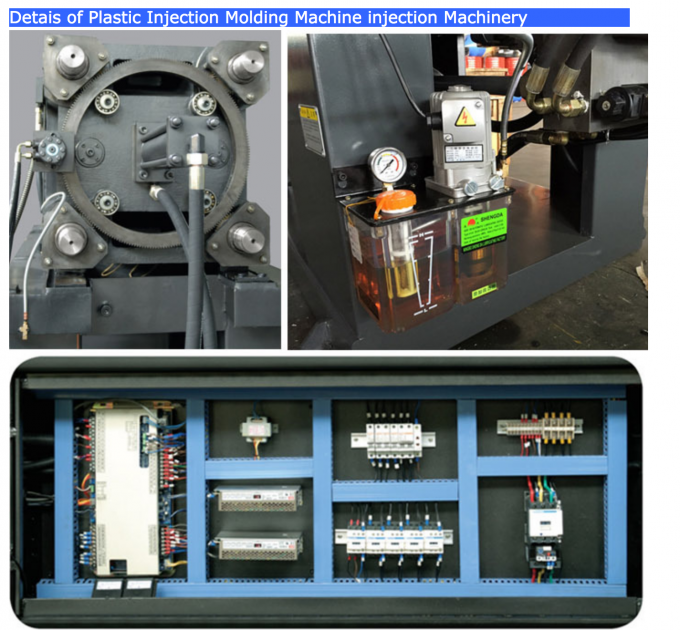

The equipment is adopted The special PET screw can significantly improve the plasticizing speed and pellet weight, reduce the plasticizing speed and display weight, reduce the plasticizing temperature, reduce the shear performance, and achieve better transparency.· the servo motor control system is 30% ~ 50% energy saving, and the variable pump control system energy saving is 25% ~ 45%.· our company has different models for different production and bottle shape, which can be used by customers.· the device increases the ejection force jet stroke and accepts PET molding.· adopt fully enclosed safety doors to ensure sanitary and thermal control requirements.· equipped with hot runner system interface.· we provide turnkey project, customized mold, injection molding machine, PET stretch blow molding machine and auxiliary equipment, etc.Parameters of PET preformed injection molding machine

Product Advantage

- All models has servo and non – servo,you can make your own choose.

- Applicable for all thermoplastic material such as PP, PE, PET, PC, PS, PVC, ABS, SAN etc, and it is used to produce preforms, caps, handles, containers, daily necessities, Hardware /kitchenware as well as other plastics products.

- Easy to control, very energy efficient.

- The machine has the advantages of beauty, durability, energy saving and environmental protection.

- Applicable to PET,PP, PE, PET, PC, PS, PVC, ABS, SAN and other thermoplastic materials for production of prefabricated parts, bottle caps, handles, containers, daily supplies, hardware/kitchenware and other plastic products.

- Save electricity about 35% ~ 38%, investment recovery time 6-12 months. It is the best ideal product to save electricity in the user factory.

- We have different series of injection molding machines to meet your different product needs.

- PLC, Japanese yuken hydraulic system.

- Design according to CE standard.

Specifications

| Model | MT–PI323 | |

| injection | A | B |

| screw diameter(mm) | 45 | 48 |

| shot size (theoretical) | 460cm³ | 525cm³ |

| shot weight (g) | 415 | 472 |

| injection pressure(Mpa) | 188 | 165 |

| injection rate(g/s) | 140 | 159 |

| screw L/D ratio (L/D) | 22 | 20.6 |

| screw speed (r.p.m) | 0-180 | |

| nozzle diameter(Srmm) | 20 | |

| clamping | ||

| clamp tonnage(KN) | 2000 | |

| toggle stroke | 445 | |

| mold thickness | 190-470 | |

| space between tie-bars(mm) | 490×464 | |

| ejection tonnage(mm) | 155 | |

| ejection tonnage(KN) | 70 | |

| ejection number(piece) | 5 | |

| hole diameter(mm) | 125 | |

| others | ||

| heat power | 11.6 | |

| Max. pump pressure(Mpa) | 16 | |

| pump motor power(kw) | 17 | |

| valve size(mm) | 16 | |

| machine dimension(m) | 5.4×1.6×1.75 | |

| machine weight(T) | 6 | |

| oil tank capacity(L) | 270 | |

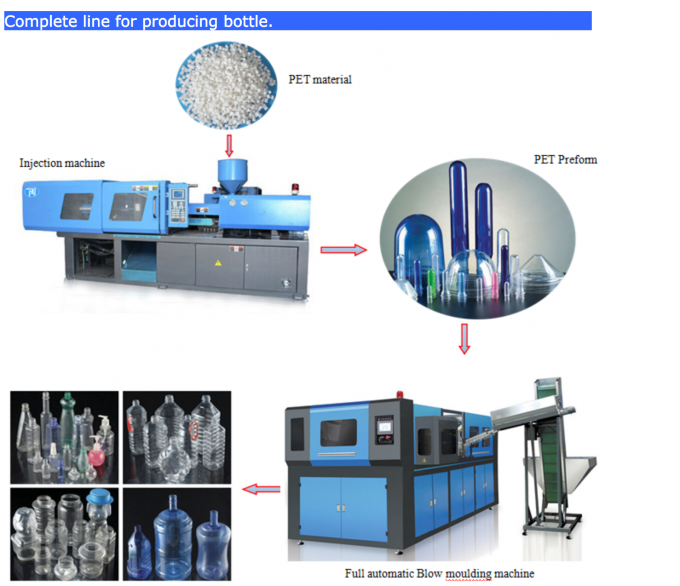

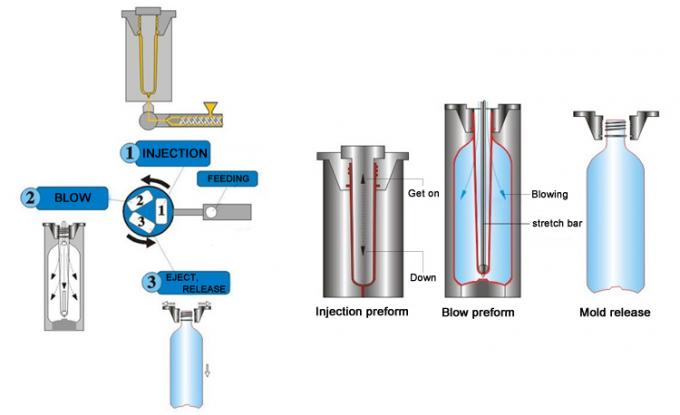

Flow Chart

Complete ling for production bottle

Product show

OutPut Products

Packaging

Our services

- Your enquiry for our products and prices will be answered within 24 hours.

- Well trained and experienced people can certainly answer all your English queries.

- Your company's business relationship with us will be kept confidential to any third party.

- And provide perfect after-sales service. If you have any questions, please contact with us ,we will replace spare for free!

- OEM and ODM projects are highly welcomed. We have a strong r&d team here to help.

-

160T – 1000T Plastic Injection Molding Machine Automatic / Semi Automatic

160T – 1000T Plastic Injection Molding Machine Automatic / Semi Automatic

Plastic injection molding Machine for plastic PET Bottle Pre...

→ -

2000BPH – 10000BPH PET Preform Injection Molding Machine For Bottle Preform / Bottle Cap

2000BPH – 10000BPH PET Preform Injection Molding Machine For Bottle Preform / Bottle Cap

The PET preformed injection molding machine from our company...

→ -

Multifunctional Plastic Injection Molding Machine 60T – 4000T Capacity

Multifunctional Plastic Injection Molding Machine 60T – 4000T Capacity

Our plastic Injection molding machine is able to produce all...

→ -

170 Ton Automatic Plastic Injection Moulding Machine Horizontal Style Preform Injection

170 Ton Automatic Plastic Injection Moulding Machine Horizontal Style Preform Injection

Applicable to PP, PE, PET, PC, PS, PVC, ABS, SAN and other t...

→