Live Chat

Click the buttonPET Bottle Drinking Water Filling Machine 5000 BPH – 14000 BPH For Mineral Water

Efficient thermal filler/filling equipment integration rinser/filler/capper on one device, its broad scope, filling production can BPH from 3000 to 3000 BPH, can be applied to drinking water, fruit juice, tea, sports drinks and energy drinks, and other liquid material, the packing is suitable for glass bottles, and various kinds of PET plastic bottles, including PET, PE and so on, the bottle volume can be 300 ml to 25000 ml

Products

-

Bag Filling Machine

-

Beverage Filling Line

-

Biscuit Making Machine

-

Biscuit Production Line

-

Bottle Blowing Machine

-

Carbonated Drink Production Line

-

Cosmetic Filling Machine

-

Drink Production Line

-

Drinking Water Filling Machine

-

Drinking Water Production Line

-

Edible Oil Production Line

-

Fruit Juice Processing Line

-

Juice Filling Machine

-

Plastic Injection Molding Machine

-

Snack Food Production Line

-

UHT Milk Processing Line

-

Water Treatment Systems

-

Vertical Packaging Machine

-

Other Packaging Machine

-

Pillow Type Packaging Machine

-

Pre-made Pouch Packing Machinery

-

Measuring Equipment

-

Cup Filling Machines

-

Conveyor Equipment

-

Auxiliary Equipment

| Type: | Pure Water Filling Machine | Condition: | New |

|---|---|---|---|

| Application: | Other | Packaging Type: | Other, Bags, Barrel, Bottles, Cans, |

| Certification: | CE | Type:: | Filling Machine |

| Application:: | Beverage, Chemical, | After-sales Service Provided:: | Overseas Service Center Available |

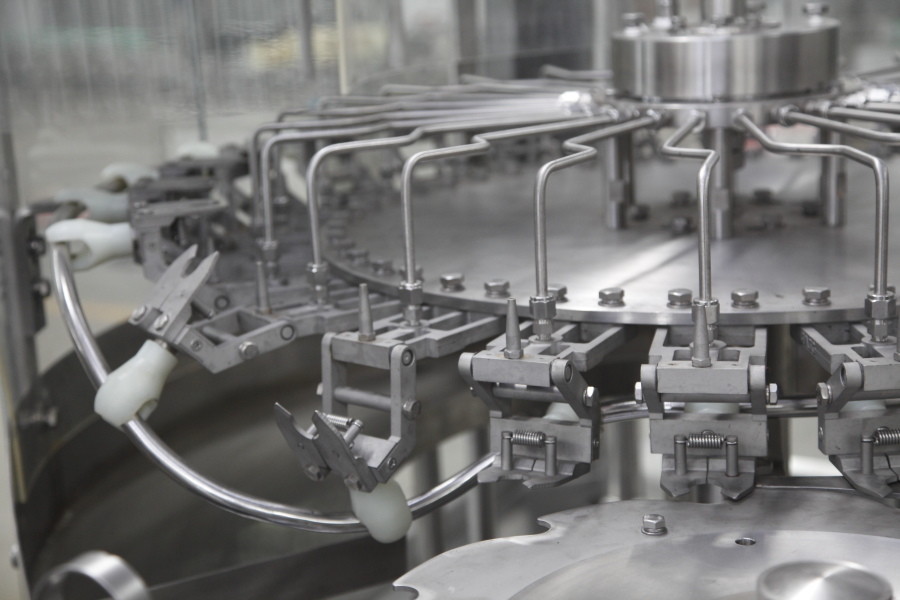

Stable PET Bottle 5000 BPH – 14000 BPH Drinking Water Filling Machine For Mineral Water , Pure Water

Product Description

Efficient thermal filler/filling equipment integration rinser/filler/capper on one device, its broad scope, filling production can BPH from 3000 to 3000 BPH, can be applied to drinking water, fruit juice, tea, sports drinks and energy drinks, and other liquid material, the packing is suitable for glass bottles, and various kinds of PET plastic bottles, including PET, PE and so on, the bottle volume can be 300 ml to 25000 ml, the equipment is stable and efficient, is small and medium-sized enterprise preferred

Proudct Features

- The device is filled with a drip proof device to ensure accurate filling and no leakage.

- Famous electrical and pneumatic components, low failure rate, stable and reliable, long service life;

- All contact parts are made of 304 # stainless steel. Easy to disassemble, easy to clean, comply with food hygiene requirements, eliminate the second pollution;

- It is equipped with automatic mixing system to ensure more uniform mixing of material filling process.

- The filling quantity and filling speed regulation is simple, no bottle, the small bottle does not fill function, the automatic seasoning, the appearance is beautiful;

- No need to replace parts can be used for different shapes of bottles filling, easy to use;

Product Show:

Secifications

All main components makers are world-known manufacturers.

| Model | MT32-32-10 | MT40-40-12 | MT50-50-15 | MT 60-60-15 | MT72-72-18 | MT 80-80-18 |

| Production Capacity(500ml b/h) | 12000-15000 | 18000-22000 | 22000-25000 | 25000-28000 | 28000-30000 | 35000-36000 |

| Washing heads | 32 | 40 | 50 | 60 | 72 | 80 |

| Filling heads | 32 | 40 | 50 | 60 | 72 | 80 |

| Capping heads | 10 | 12 | 15 | 15 | 18 | 18 |

| Suitable Bottles | PET Round or Square | |||||

| Bottle Diameter(mm) | 50-90 | |||||

| Bottle height(mm) | 150-340 | |||||

| Compressed Air Pressure(Mpa) | 0.3-0.7 | |||||

| Washing Medium | Aseptic Water | |||||

| Washing water pressure(Mpa) | 0.25 | |||||

| Power(Kw) | 6 | 7.5 | 9.5 | 11.2 | 15 | 18 |

| Overall sizes(cm) | 380×280×290 | 460×280×290 | 545×330×290 | 620×450×230 | 650×480×285 | 650×500×285 |

| Weight(kg) | 5600 | 8500 | 9800 | 12800 | 15000 | 18000 |

Output Product

Our Service

- We offer a professional production line plan, and give reasonable technical advice to your needs.

- Our company offers 2 years warranty, 2 years spare parts free replacement.

- Timely communication, usually within 12 hours to ensure that you can reply to your questions.

- Technical support: provide on-site installation, debugging and training.

- Document: provide product user manual, equipment drawing, operation specification, notes and other documents.

Cooperation process

Inquiry – send quotation – confirm the order – company's proforma invoice and contract.

Method of payment:

A deposit of 30% T/T payment – prepare machines – you send the bottle samples sent our company – we will be the first to work in our company, and debugging equipment with the bottle samples,-we send the equipment and video to you,-your company personnel to come to my company to check the machine – pay the balance payment 70% payment – we arrange delivery – the machine arrive at your factory, our engineers will provie door sevie for installation, commissioning, training

-

300ml-2L PET Bottle Water Filling Machine , Mineral Water Bottling Machine

300ml-2L PET Bottle Water Filling Machine , Mineral Water Bottling Machine

Multifunctional automatic bottle washing, filling and cappin...

→ -

100-5000 BPH Drinking Water Filling Machine Single / Double Nozzle For Pet Bottle

100-5000 BPH Drinking Water Filling Machine Single / Double Nozzle For Pet Bottle

The series of bottled water filling lines is used to produce...

→ -

3 In 1 Automatic Washing Filling Capping Machine For Food / Beverage CE Standard

3 In 1 Automatic Washing Filling Capping Machine For Food / Beverage CE Standard

The machine is mainly used in the beverage filling operation...

→ -

Fully Automatic 3 In 1 Water Filling Machine , Carbonated Beverage Bottling Equipment

Fully Automatic 3 In 1 Water Filling Machine , Carbonated Beverage Bottling Equipment

Fruit juice disinfector or juice storage tank -- high lever ...

→