Products

-

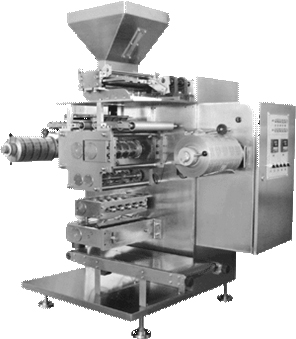

Bag Filling Machine

-

Beverage Filling Line

-

Biscuit Making Machine

-

Biscuit Production Line

-

Bottle Blowing Machine

-

Carbonated Drink Production Line

-

Cosmetic Filling Machine

-

Drink Production Line

-

Drinking Water Filling Machine

-

Drinking Water Production Line

-

Edible Oil Production Line

-

Fruit Juice Processing Line

-

Juice Filling Machine

-

Plastic Injection Molding Machine

-

Snack Food Production Line

-

UHT Milk Processing Line

-

Water Treatment Systems

-

Vertical Packaging Machine

-

Other Packaging Machine

-

Pillow Type Packaging Machine

-

Pre-made Pouch Packing Machinery

-

Measuring Equipment

-

Cup Filling Machines

-

Conveyor Equipment

-

Auxiliary Equipment

Automatic RO Water Treatment Plant , Stainless Steel Water Treatment Equipment

Litchi / Pulp Juice Filling Machine High Capacity Semi- Automatic CE Certificate

High Capacity Carbonated Drink Production Line Machine For 500ml-2500ml Bottle

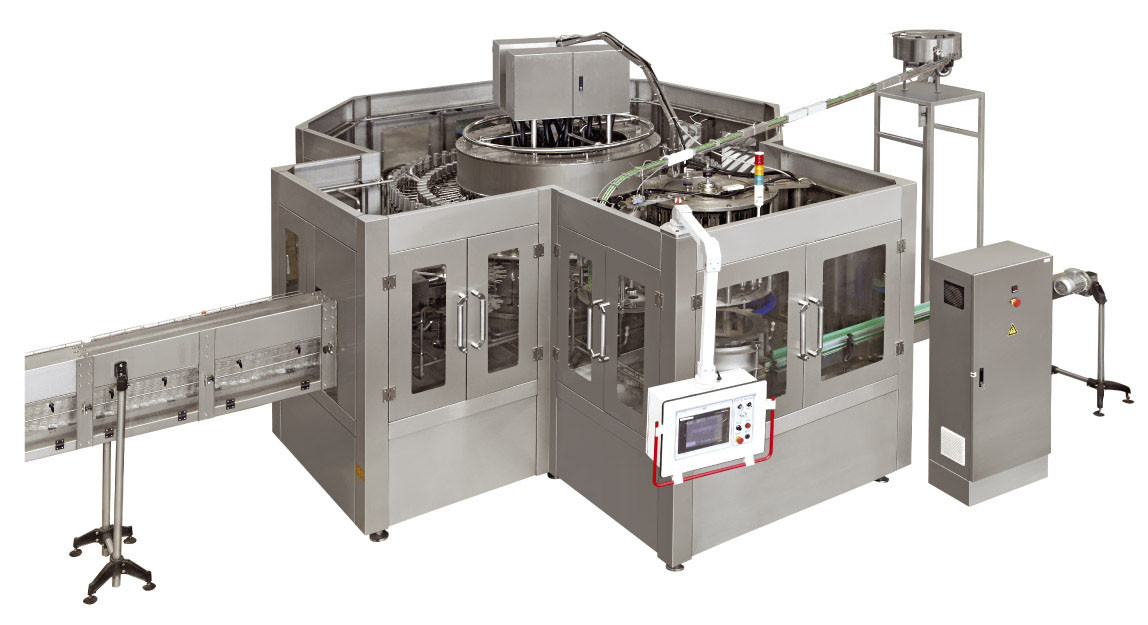

3 In 1 Plastic Bottle Beverage Filling Machine , Automatic Soft Drink Filling Machine

Red Bull Energy Drink Production Line Automatic For Glass / PET Bottle

Fully Automatic Drinking Water Filling Machine 600-3000BPH For 5 Gallon PET Bottle

Bottled Mineral Drinking Water Production Machine / Filling Production Line

SUS304 PET Bottle Edible Oil Bottle Filling Machine For Non Viscous Liquid Filling

Plastic Bottle Soft Drink Filling Machine

bottle fill machine - accupacking® Official Site

Enjoy Great Deals and Discounts On an Array Of Products From Various Brands. Get Deals and Low Prices On bottle fill machine At accupacking

Auto bottle filling machine - Isolator - Liquid filling

Optimum solution for pharma liquid filling in Class A. Ideal for small batches. Flexible solution, reduce process validation costs and prevent leaking bottles.

Vevor® Liquid Filling Machines - Vevor® Official Online Store

Shop high quality Liquid Filling Machines at honest prices. Free Shipping on most orders. Shop our huge selection of tools & equipment online with a 12-month warranty.

The Ultimate Carbonated Beverage Filling Machine

The carbonated soft drink filling machine has versatile applications that allow it to handle a wide range of carbonated beverages: Cola, juices, and sodas – The machine can smoothly fill these classic carbonated soft drinks while minimizing foaming.

| Automatic Liquid Filling Machines

Our machines can handle plastic bottle filling, from smaller containers to large jugs. Aluminum cans are growing in popularity over plastic for their recyclability and lightweight handling, though the material can be thin before it is filled.

Reliable Bottling Lines With Filling Machine Solutions

Our juice filling machine and hot filling line handle bottle sizes from 250ml to 2L, providing efficient and precise filling for all your beverage production needs.

Bottle & Liquid Filling Machines | Inline Filling Systems

Find liquid filling machines, bottle capping equipment & unscramblers at reasonable prices. All bottling equipment is manufactured by ACASI Machinery.

Hanchen Liquid Filling Machine 1-118 Ounce Bottle Filler ...

SUPER FAST 118 OZ/MIN FILLING SPEED: Powered by a 118 Ounce/min powerful diaphragm pump, this HC-350 liquid filling machine can handle a 8 Oz bottle within 4s if your product is similar to water. NOTE: when liquid is viscous, the filling speed will decrease a lot.

Liquid Filling Solutions | Bottle Filling Machines - Accutek

Accutek liquid filling machines handle products ranging from sports drinks to peanut butter. There are four technologies used to fill a container with a measured amount of liquid product; timed flow, fill to level, metered flow, and fill by weight.

Custom Plastic Bottle Soft Drink Filling Machine ...

Our plastic bottle soft drink filling machine is built using state-of-the-art technology, which ensures that each bottle is filled to the required level with the appropriate volume. Other features include its compatibility with different bottle shapes and sizes, ease of operation, low maintenance, and minimal downtime.

Bottle & Liquid Filling Machines | Inline Filling Systems

The Accu-Doser is an 8 head automatic high precision mini dose filling/dispensing machine capable of accurately filling from 0.1 ML to 200 ML. The Accu-Doser was designed to fill trays of small bottles, vials, syringes, and cartridges.

Carbonated Soft Drink Filling Machine - HZM Machinery

The Carbonated Soft Drink Filling Machine is primarily used for washing, filling, and capping in the production lines of carbonated drinks and mineral water. This equipment is suitable for the production of carbonated beverages in PET bottles, glass bottles, and cans of various shapes.

Carbonated Soft Drink (CSD) Filling Machine - Reliable

Adopts different filling methods, and comprehensively considers the sanitation of the operation space and the layout of the equipment. Based on the differences in output, size, shape, bottle caps and packaging materials, promise to make your products have a perfect performance during the filling process and on the shelf.