Live Chat

Click the buttonSmall Beer Alcoholic Drink Production Line 100ml – 2500ml 12000 BPH Silver Gray

adopts frequency control of motor speed, low energy, the automatic operation of the PLC control all completed, and the equipment have three basic function, washing, filling and capping, special filling valve filling speed, filling liquid level control and accurate correction, ensure accurate liquid level does not leak.

Products

-

Bag Filling Machine

-

Beverage Filling Line

-

Biscuit Making Machine

-

Biscuit Production Line

-

Bottle Blowing Machine

-

Carbonated Drink Production Line

-

Cosmetic Filling Machine

-

Drink Production Line

-

Drinking Water Filling Machine

-

Drinking Water Production Line

-

Edible Oil Production Line

-

Fruit Juice Processing Line

-

Juice Filling Machine

-

Plastic Injection Molding Machine

-

Snack Food Production Line

-

UHT Milk Processing Line

-

Water Treatment Systems

-

Vertical Packaging Machine

-

Other Packaging Machine

-

Pillow Type Packaging Machine

-

Pre-made Pouch Packing Machinery

-

Measuring Equipment

-

Cup Filling Machines

-

Conveyor Equipment

-

Auxiliary Equipment

| Type: | Automatic Soda Filling Machine | Application: | Beverage |

|---|---|---|---|

| Packaging Type: | Bottles | Packaging Material: | Plastic |

| Automatic Grade: | Automatic, Full Automatic | Driven Type: | Electric |

| Capacity: | 10000-12000BPH | Material: | SUS304 Food Stage |

| Control: | PLC Touch Screen Control | Suitable Bottle: | 0.3-2L PET Bottle |

| Color: | Silver Gray | Filling Type: | Gravity Pressure Filling |

Autoamtic100ml-2500ml 12000BPH Small Beer Alcoholic Drink Production Line /Small Beer Alcoholic Drink filling Machine

Product Description

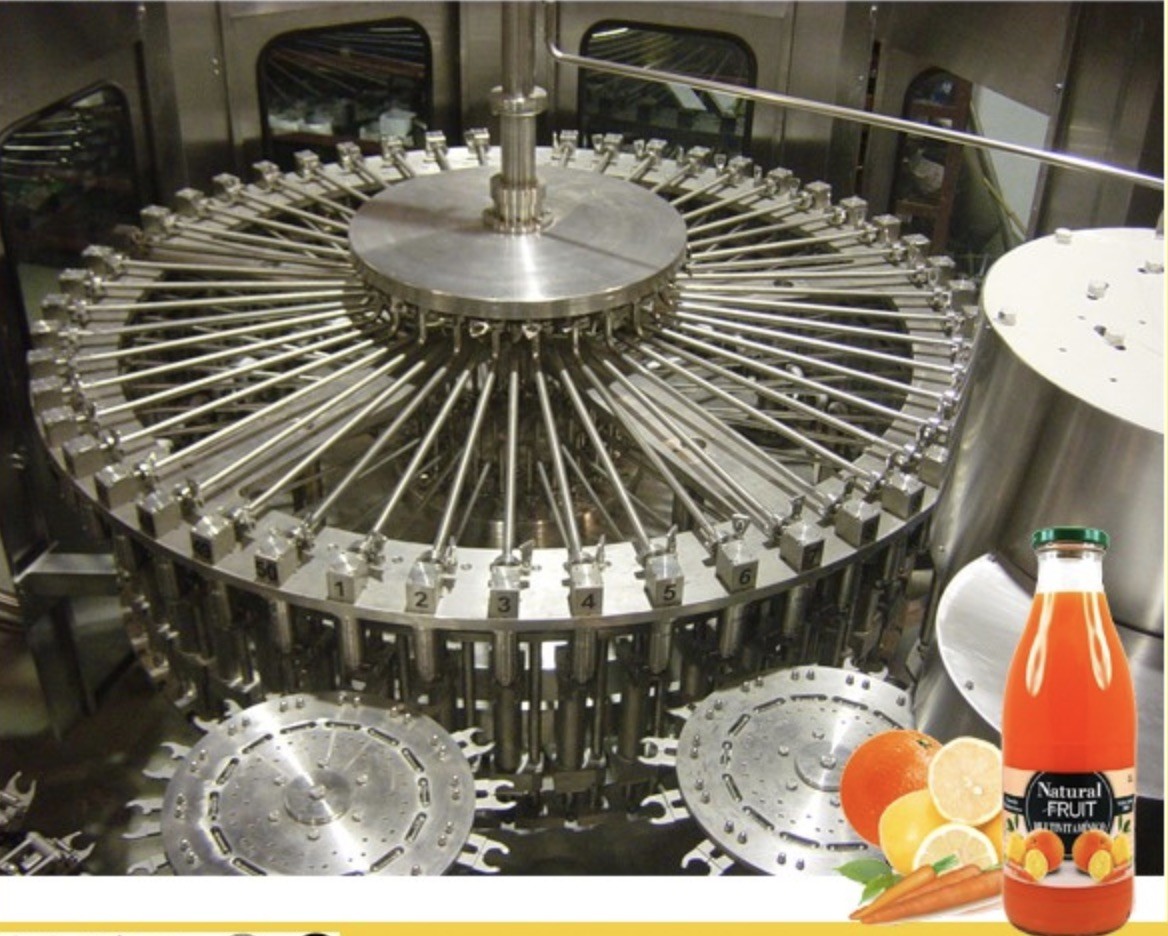

Beer beverage filling machine is used to produce all kinds of beer drink, juice, mineral water, pure water and other non-carbonated drinks. Machine adopts frequency control of motor speed, low energy, the automatic operation of the PLC control all completed, and the equipment have three basic function, washing, filling and capping, special filling valve filling speed, filling liquid level control and accurate correction, ensure accurate liquid level does not leak. Applicable to PET bottles, glass bottles, using normal temperature and pressure filling.

Product Advantage

- Using high speed filling valve, the liquid level is accurate, no overflow and no waste

- Adopt overload protection system, safety alarm system, error warning system, ensure the safety of operators and equipment.

- All parts in contact with the product adopt quality food grade SUS304, corrosion resistant, easy to clean, no secondary pollution.

- The sealing head adopts the constant torque magnetic device to ensure the quality of cover and no damage to the cover.

- The machine has simple operation, compact structure, perfect control system and high degree of automation.

- For a variety of bottles, only a few parts need to be replaced to apply to a variety of other bottles.

- The machine has a high efficient hat system and a perfect protective gear.

- The electrical system is the core part of the whole equipment, so in the configuration of electrical equipment, we are all the world famous brands, such as Siemens, omron, mitsubishi, etc.

- The operating system has the function of production speed control, bottle cap shortage inspection, bottle seal production suspension, output statistics and so on.

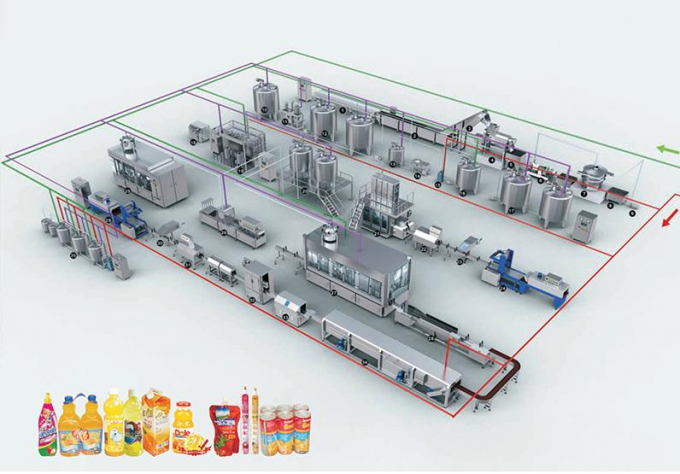

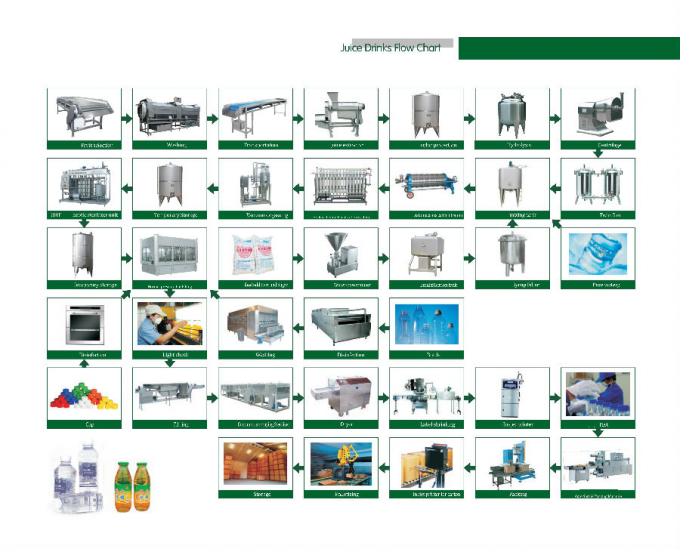

Flow Chart:

We are able to supply whole production line for juice making ,Send us now We will make a business proposal for you with professional advice of business.

Product Show:

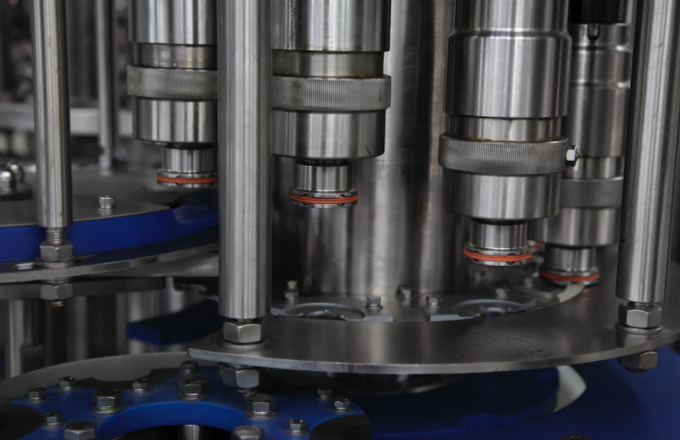

Details of Machine

|

|

|

Filling Parts: |

|

|

Capping Parts: Raw material: Food Grade Stainless Steel SUS304 Capping type: Rotary screw capping Adopts Italy advanced technology, more stable and durable. |

|

PLC and Touch Screen Brand: Siemens Original: Japan Using international brand electrical components to ensure machines running in good condition for longer time. |

|

|

|

|

Secifications:

| Model | MT8-8-3 | MT12126 | MT18186 | MT24248 |

| Number of washing, filling and capping heads | 8-8-3 | 12-12-6 | 18-18-6 | 24-24-8 |

| Production capacity(500ml)(B/H) | 2000BPH | 4000 | 7000-8000 | 10000-12000 |

| Suitable bottle specification(mm) | volume=330-2000ml | φ=50-110 H=150~340mm volume=330-2500ml | ||

| Washing pressure(kg/cm 2 ) | 2-3 | |||

| Motor power(kw) | Main motor1.9kw | Main motor3.5kw | Main motor4.0kw | Main motor4.8kw |

| Overall dimensions (mm) | 1900*1420*2000 | 2450*1800*2400 | 2650*1900*2400 | 2900*2100*2400 |

| Weight (kg) | 1500 | 2500 | 3500 | 4500 |

| Model | MT323210 | MT404012 | MT505015 | MT606015 |

| Number of washing, filling and capping heads | 32-32-10 | 40-40-12 | 50-50-15 | 60-60-15 |

| Production capacity(500ml) (B/H) | 12000-15000 | 15000-18000 | 20000-22000 | 22000-25000 |

| Suitable bottle specification(mm) | φ=50-110 H=150~340mm Volume=330-2500ml | |||

| Washing pressure(kg/cm 2 ) | 2-3 | |||

| Motor power(kw) | Main motor7.6kw | Main motor8.3kw | Main motor 9.6kw | Main motor 15Kw |

| Overall dimensions (mm) | 4100*2000*2400 | 4550*2650*2400 | 5450*3210*2400 | 5500*3510*2400 |

| Weight (kg) | 6500 | 8500 | 9800 | 12000 |

Output Product

Our Supplier

Our Service

.

- Answer any questions you have within 24 hours.

- Send machine pictures in production.

- The machine test runs for more than 8 hours and sends the test video.

- We can provide machine video for reference.

- Install, debug and provide training services.

- Welcome to the factory

- Provide all the information you need.

- One year warranty, free accessories during the warranty period, the cost of selling accessories a year later.

- Update the production schedule weekly.

Package

Contact Us

Send us inquery now !we will send you best quotation with latest promotion in 12hours!

-

Carbonated Soft Drink Filling Machine , Aluminum Tin Can Gas Beverage Production Line

Carbonated Soft Drink Filling Machine , Aluminum Tin Can Gas Beverage Production Line

The quality of water is crucial to the success of soft drink...

→ -

Automatic Soft Drink Filling Machine , Plastic Bottle Filling Machine ODM Available

Automatic Soft Drink Filling Machine , Plastic Bottle Filling Machine ODM Available

Carbonated soft drink production line is mainly used for aut...

→ -

6000 BPH – 8000BPH Soda Water / Carbonated Beverage Filling Machine For 500 ML PET Bottle

6000 BPH – 8000BPH Soda Water / Carbonated Beverage Filling Machine For 500 ML PET Bottle

Carbonated beverage production /filling machine is widely...

→ -

Plastic / Glass Bottling Automatic Filling And Capping Machine For Different Shapes

Plastic / Glass Bottling Automatic Filling And Capping Machine For Different Shapes

With the advanced atmospheric gravity filling, the filling ...

→