Products

-

Bag Filling Machine

-

Beverage Filling Line

-

Biscuit Making Machine

-

Biscuit Production Line

-

Bottle Blowing Machine

-

Carbonated Drink Production Line

-

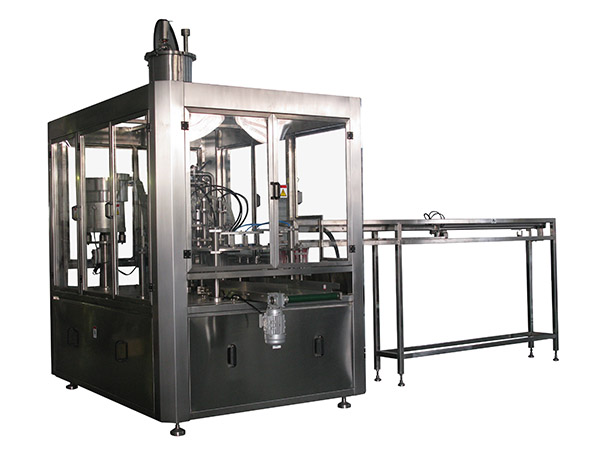

Cosmetic Filling Machine

-

Drink Production Line

-

Drinking Water Filling Machine

-

Drinking Water Production Line

-

Edible Oil Production Line

-

Fruit Juice Processing Line

-

Juice Filling Machine

-

Plastic Injection Molding Machine

-

Snack Food Production Line

-

UHT Milk Processing Line

-

Water Treatment Systems

-

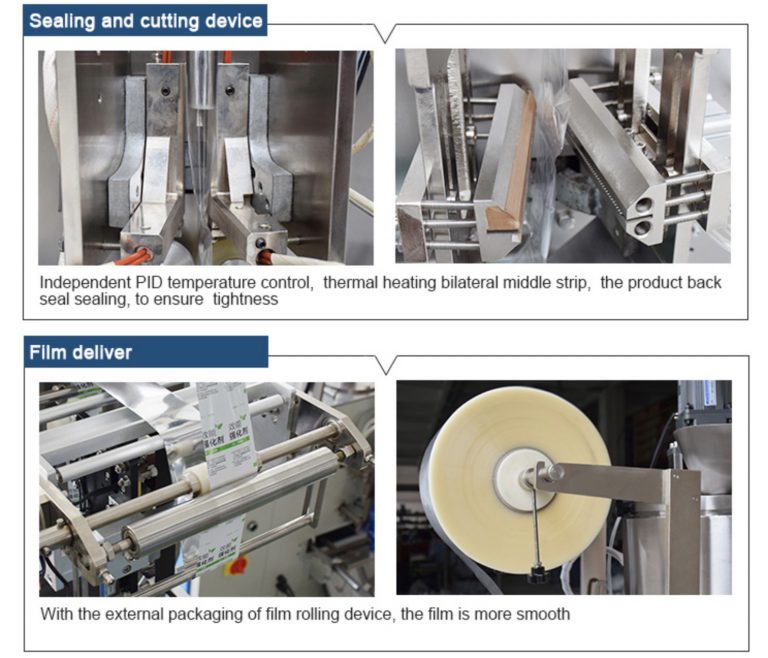

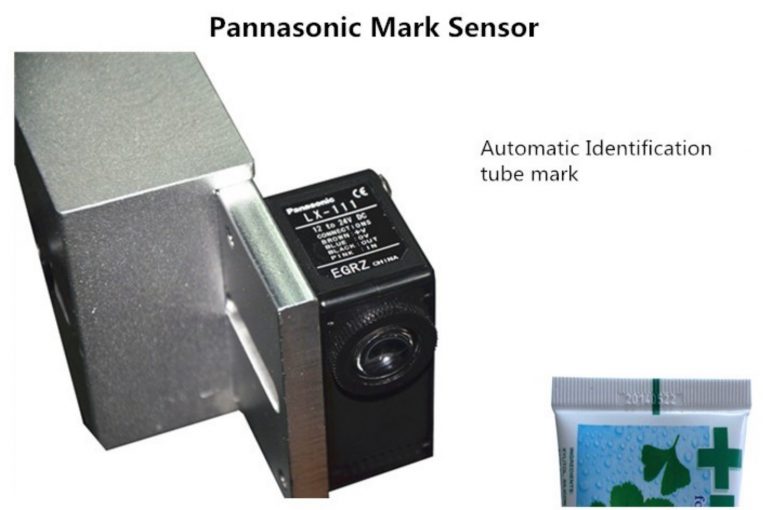

Vertical Packaging Machine

-

Other Packaging Machine

-

Pillow Type Packaging Machine

-

Pre-made Pouch Packing Machinery

-

Measuring Equipment

-

Cup Filling Machines

-

Conveyor Equipment

-

Auxiliary Equipment

Automatic RO Water Treatment Plant , Stainless Steel Water Treatment Equipment

Litchi / Pulp Juice Filling Machine High Capacity Semi- Automatic CE Certificate

High Capacity Carbonated Drink Production Line Machine For 500ml-2500ml Bottle

3 In 1 Plastic Bottle Beverage Filling Machine , Automatic Soft Drink Filling Machine

Red Bull Energy Drink Production Line Automatic For Glass / PET Bottle

Fully Automatic Drinking Water Filling Machine 600-3000BPH For 5 Gallon PET Bottle

Bottled Mineral Drinking Water Production Machine / Filling Production Line

SUS304 PET Bottle Edible Oil Bottle Filling Machine For Non Viscous Liquid Filling

Three In One BFS Blow Filling Sealing Machine

ALPS | Leaders of (BFS) Blow Fill Seal Technology | Welcome to

ALPS - Automated Liquid Packaging Solutions, LLC - Blow Fill Seal Technology is a supplier of Blow/Fill/Seal (BFS) / Form Fill Seal (FFS) sterile filling machines. 1. Form or Blow mold a plastic container; 2. Aseptically Fill the container; 3.

Three in one to perfection - Pharma World

Jun 20, 2014 In 1963 he invented and built his first blow-fill-seal machine. This BFS technology has numerous advantages over conventional packaging

Aseptic Filling With BFS (Blow Fill Seal) bottelpack® System

The BFS bottelpack® aseptic system from rommelag® is designed for Click here to download a datasheet on the Blow-Fill-Seal bottelpack® system. bottelpack® aseptic machines are designed in a modular structure and have an integrated clean room Blow-Fill-Seal bottelpack® Type 324 Three In One To Perfection.

Blow/Fill/Seal Demo 303 500ml - YouTube

Aug 29, 2008 We have the capability of providing molds, machine upgrades, deflashing systems, as well as used and reconditioned blow/fill/seal machines.

APT Med. Blow-Fill-Seal - Rao Design

We make molds for all types of Blow Fill Seal Machines. Do not Now a days many companies prefer to produce single unit dose containers and BFS is one of

LIQUID SPECIAL BLOW-FILL-SEAL - Rieckermann

A Blow-Fill-Seal (BFS) machine minimizes contamination risk and reduces machine interfaces is a key factor in getting three steps from one machine only.

Blow-fill-seal (BFS) | Technologies - Unither Pharmaceuticals

Preservative-free single-unit-doses BFS. Blow-Fill-Seal (BFS). We are the worlds number one producer of BFS products, and have been making them products

Blow / Fill / Seal | Catalent

Catalent offers customized, aseptic packaging for sterile respiratory and support systems to meet all your Blow/Fill/Seal (B/F/S) manufacturing needs. ensuring a reliable global supply and an uncompromising commitment to quality. The basic concept of the system is the combination of three major processing steps:

Sterilization of Blow-Fill-Seal Equipment for Aseptic Filling

Jul 2, 2014 Blow-fill-seal (BFS) technology—in which a polymeric container is formed, organisms and more than a three-log endotoxin reduction (1).

Folie 1 - The Pharmaceutical BFS International Operators Association

Mar 13, 2018 3. BFS is an production process based on extrusion blow molding of polymer containers. However using compact and fully automated machines that: -1- - 4- Seal the container tightly immediately after filling. BFS Definition.

ALPS | Leaders of (BFS) Blow Fill Seal Technology | Welcome to

ALPS - Automated Liquid Packaging Solutions, LLC - Blow Fill Seal Technology is a supplier of Blow/Fill/Seal (BFS) / Form Fill Seal (FFS) sterile filling machines. 1. Form or Blow mold a plastic container; 2. Aseptically Fill the container; 3.

Three in one to perfection - Pharma World

Jun 20, 2014 In 1963 he invented and built his first blow-fill-seal machine. This BFS technology has numerous advantages over conventional packaging

Aseptic Filling With BFS (Blow Fill Seal) bottelpack® System

The BFS bottelpack® aseptic system from rommelag® is designed for Click here to download a datasheet on the Blow-Fill-Seal bottelpack® system. bottelpack® aseptic machines are designed in a modular structure and have an integrated clean room Blow-Fill-Seal bottelpack® Type 324 Three In One To Perfection.

Blow/Fill/Seal Demo 303 500ml - YouTube

Aug 29, 2008 We have the capability of providing molds, machine upgrades, deflashing systems, as well as used and reconditioned blow/fill/seal machines.

APT Med. Blow-Fill-Seal - Rao Design

We make molds for all types of Blow Fill Seal Machines. Do not Now a days many companies prefer to produce single unit dose containers and BFS is one of

LIQUID SPECIAL BLOW-FILL-SEAL - Rieckermann

A Blow-Fill-Seal (BFS) machine minimizes contamination risk and reduces machine interfaces is a key factor in getting three steps from one machine only.

Blow-fill-seal (BFS) | Technologies - Unither Pharmaceuticals

Preservative-free single-unit-doses BFS. Blow-Fill-Seal (BFS). We are the worlds number one producer of BFS products, and have been making them products

Blow / Fill / Seal | Catalent

Catalent offers customized, aseptic packaging for sterile respiratory and support systems to meet all your Blow/Fill/Seal (B/F/S) manufacturing needs. ensuring a reliable global supply and an uncompromising commitment to quality. The basic concept of the system is the combination of three major processing steps:

Sterilization of Blow-Fill-Seal Equipment for Aseptic Filling

Jul 2, 2014 Blow-fill-seal (BFS) technology—in which a polymeric container is formed, organisms and more than a three-log endotoxin reduction (1).

Folie 1 - The Pharmaceutical BFS International Operators Association

Mar 13, 2018 3. BFS is an production process based on extrusion blow molding of polymer containers. However using compact and fully automated machines that: -1- - 4- Seal the container tightly immediately after filling. BFS Definition.