Live Chat

Click the button100~500 kg/Hr Snack Food Production Line Chocolate Ball / Chocolate Pillow Filled Puff

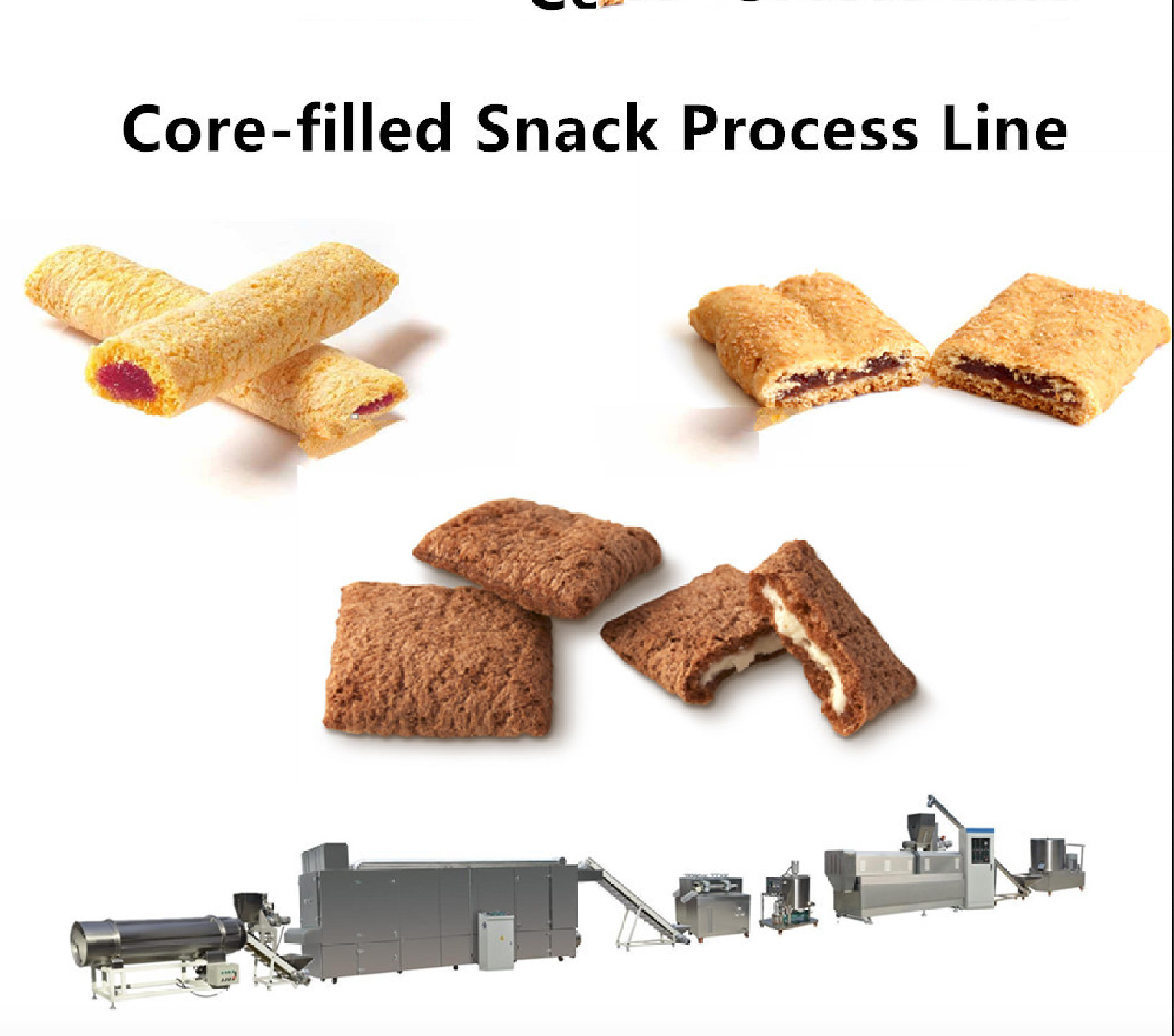

The main application of this biscuit production line is to produce various shapes and flavors of biscuits filled which core filled with chocolate including like chocolate energy bar, chocolate ball, chocolate pillow snack etc with corn powder, rice flour, wheat flour, chocolate powder. to meet different kind of customers flavor requirement.

Products

-

Bag Filling Machine

-

Beverage Filling Line

-

Biscuit Making Machine

-

Biscuit Production Line

-

Bottle Blowing Machine

-

Carbonated Drink Production Line

-

Cosmetic Filling Machine

-

Drink Production Line

-

Drinking Water Filling Machine

-

Drinking Water Production Line

-

Edible Oil Production Line

-

Fruit Juice Processing Line

-

Juice Filling Machine

-

Plastic Injection Molding Machine

-

Snack Food Production Line

-

UHT Milk Processing Line

-

Water Treatment Systems

-

Vertical Packaging Machine

-

Other Packaging Machine

-

Pillow Type Packaging Machine

-

Pre-made Pouch Packing Machinery

-

Measuring Equipment

-

Cup Filling Machines

-

Conveyor Equipment

-

Auxiliary Equipment

Automatic RO Water Treatment Plant , Stainless Steel Water Treatment Equipment

Litchi / Pulp Juice Filling Machine High Capacity Semi- Automatic CE Certificate

High Capacity Carbonated Drink Production Line Machine For 500ml-2500ml Bottle

3 In 1 Plastic Bottle Beverage Filling Machine , Automatic Soft Drink Filling Machine

Red Bull Energy Drink Production Line Automatic For Glass / PET Bottle

Fully Automatic Drinking Water Filling Machine 600-3000BPH For 5 Gallon PET Bottle

Bottled Mineral Drinking Water Production Machine / Filling Production Line

SUS304 PET Bottle Edible Oil Bottle Filling Machine For Non Viscous Liquid Filling

| Brand Name: | Qualipak | Model Number: | MT500A |

|---|---|---|---|

| Application: | Puff Snack/Corn Snack/Extrusion Snack Process Line, Puff Snack/Corn Snack/Extrusion Snack Process Line | Voltage: | 220/380/450V |

| Power(W): | 22/30/37/45/55kw | Weight: | 3 Ton |

| Dimension(L*W*H): | 35000*5000*3200mm | Warranty: | 1 Year |

| Capacity: | 100~500kg/hr | Material: | Stainless Steel |

| Screw Diameter: | 64mm/60mm/90mm | Dryer Power Source: | Electricity/Gas/Diesel/LPG/Biofuel Etc |

| Die: | Standard / Customized | Moter: | Siemens |

| Invertors: | ABB/Delta | PLC: | Siemens |

Chocolate Ball, chocolate pillow filled puff snack production line

Application:

The main application of this biscuit production line is to produce various shapes and flavors of biscuits filled which core filled with chocolate including like chocolate energy bar, chocolate ball, chocolate pillow snack etc with corn powder, rice flour, wheat flour, chocolate powder. to meet different kind of customers flavor requirement.

Advantage:

- Fully automatic system with PLC,easay to operate with user friendly touch screen.

- Wide range of Formula with viarous of raw material to meet different flavor requirement.

- Easy to extend the application of machine just simplely changing the segments screw.

- It has an entirely new set of templates which is able to create all kinds of inovated shapes including stars, rings, Balls, animals, pillows, triangles, curls, chips, sticks, and also letters to meet kids and adults requirement

- Famous international components like Siemens, LG, Japan NSK to ensure the

| SPECIFICATIONS | |||

| Machines | Mixer- Conveyor- Extruder- Air Conveyor- Electric Dryer- Season;Flavor – Package | ||

| Function | Product | Corn Puff Ball, Ring, stick, Cheetos, corn curls, cereal, core-filled snack | |

| Mold | Set | Based on Product | |

| Capacity | Kg/h | 120-600kg/h | |

| Main functionality parameters | Full electric installed Power | Kw | 62 |

| Consumption Power | Kw | 40 | |

| Space Required | m³ | 130 | |

| Material Spare Parts | Motor: Siemens | Cover: Stainless Steel | |

| Invertos: Korea LG Brand | Material touch to food: Food Grade Material | ||

| Bearing: Japan NSK | Frame: Strong Carbon Steel | ||

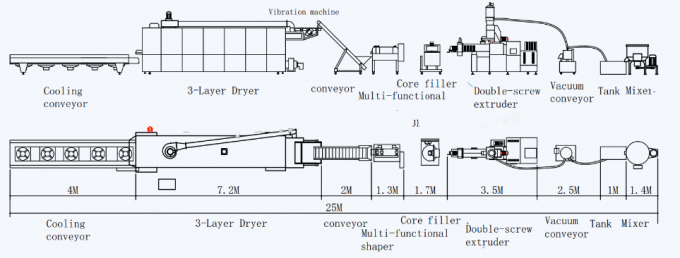

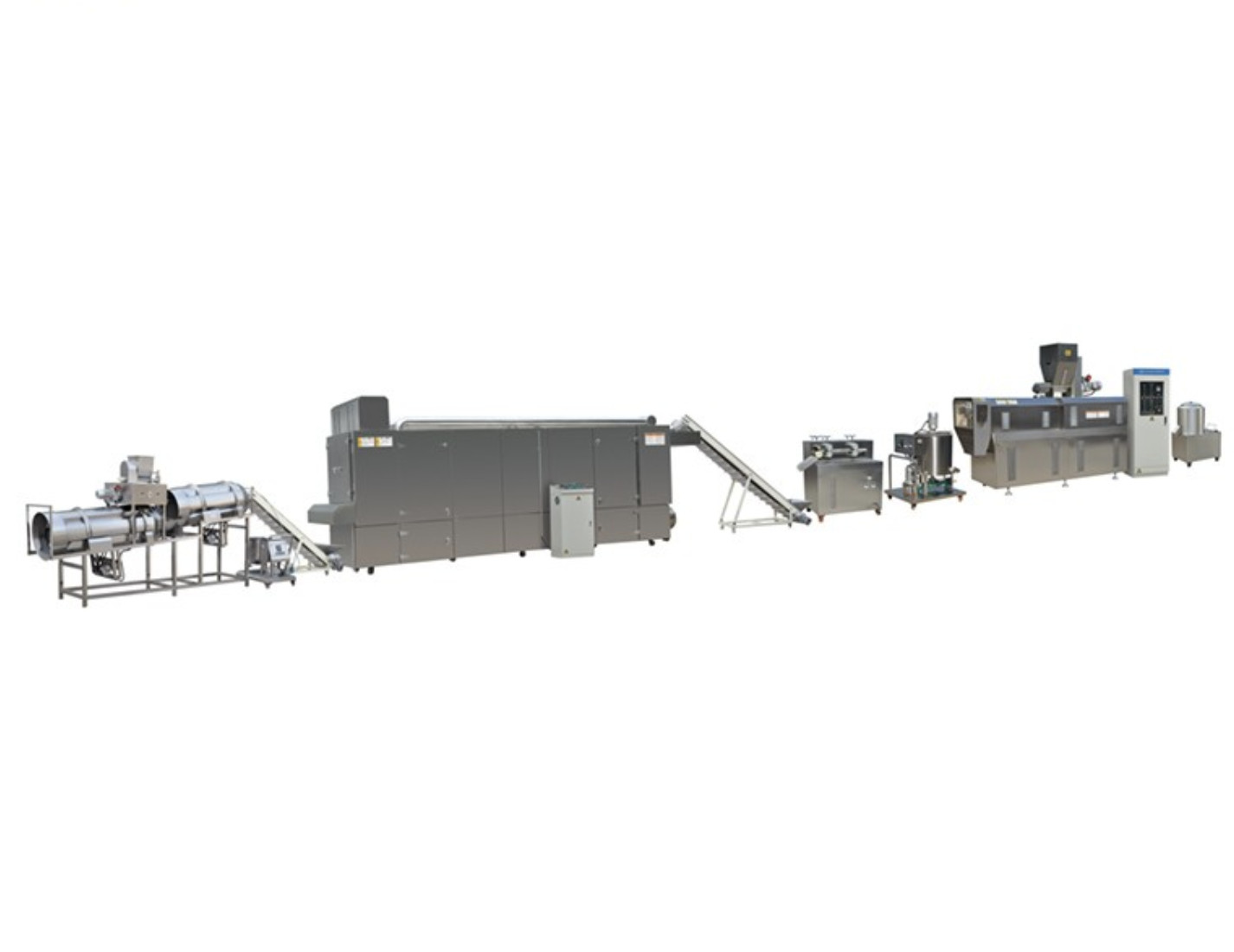

Machines of production line

Flour Mixer

We have different mode of machines with different capacity from 25kg to 100kg./batch

Capacity: 25kg/batch 55kg/batch, 80-100kg/batch Power: 3-7.5kw

Material: Stainless Steel

Application: mix raw material evenly.

Twin Screw Extruder

Capacity: 80-500kg/h

Power: 24kw, 36kw, 34kw, 55kw, 75kw

Application:

The main function is to form the material inside of barrel, screw, heating shape the product in the mould area.

Dryer

Capacity: 100-1000kg/h

it supports different heating way including: Electric, Diesel, Gas,LPG, Steam, Bio-fuel

the Temperature could be : 0-200℃

Application: reduce the moisture inside and out of raw material

Continuous Flavoring Line

Capacity: 120-500kg/h

Includes: Lift, Power flavoring hopper Drum, Oil Sprayer( which is Optional, depends on product)

it is made of stainless steel

Application:

To flavor the product with flavoring powder oil per the product required

Factory Strengh

- 15 years' experience in production and development

- Professional design and development team

- Process management and quality control in line with international quality standards

- More Than 15 years exprience of manufa

Before Shipment

- Test the machine to make it works perfect.

- Clean the machine,make it looks good.

- pack the machine with standard wooden case to make sure shipping safety.

- Wooden Cases ensure the safety shipment.

After-Sales Service

- Free Installation ,debugging and operationg oversea.

- Free taining serverce.

- Free formula provide.

- Adjust the machine with parameters.

- Free spares during first year.

Inquery now ! we will make a business proposal for you soon!

-

Chocolate Filled Cereal Snack Food Processing Equipment For Different Shape

Chocolate Filled Cereal Snack Food Processing Equipment For Different Shape

With mature of Co-extruded snacks technology, as a machinery...

→ -

Mini Chocolate Core Filled Snack Food Processing Line Small Capacity High Performance

Mini Chocolate Core Filled Snack Food Processing Line Small Capacity High Performance

The machine are made of food-grade stainless steel, he scre...

→ -

Chocolate Core Filling Puff Snack Food Production Line For Ball Low Power Consumption

Chocolate Core Filling Puff Snack Food Production Line For Ball Low Power Consumption

We supply turn-key project for Chocolate Core filling puff s...

→ -

Small Hot Wafers Cookie Production Line , Chocolate Filling Snack Production Line

Small Hot Wafers Cookie Production Line , Chocolate Filling Snack Production Line

we are specialist in chocolate production line in China,and ...

→