Live Chat

Click the buttonChocolate Filled Cereal Snack Food Processing Equipment For Different Shape

With mature of Co-extruded snacks technology, as a machinery industry leading enterprises, we developed the chocolate filled cereal snacks production line as early as 15 years ago, after many times of iteration update, our equipment becomes stable and work efficiently,it can produce a snack with two different flavors,it supports viraous of shapes including pillow, elipse cereal bar,triangle, round cereal bar, triangle cereal bar.

Products

-

Bag Filling Machine

-

Beverage Filling Line

-

Biscuit Making Machine

-

Biscuit Production Line

-

Bottle Blowing Machine

-

Carbonated Drink Production Line

-

Cosmetic Filling Machine

-

Drink Production Line

-

Drinking Water Filling Machine

-

Drinking Water Production Line

-

Edible Oil Production Line

-

Fruit Juice Processing Line

-

Juice Filling Machine

-

Plastic Injection Molding Machine

-

Snack Food Production Line

-

UHT Milk Processing Line

-

Water Treatment Systems

-

Vertical Packaging Machine

-

Other Packaging Machine

-

Pillow Type Packaging Machine

-

Pre-made Pouch Packing Machinery

-

Measuring Equipment

-

Cup Filling Machines

-

Conveyor Equipment

-

Auxiliary Equipment

Automatic RO Water Treatment Plant , Stainless Steel Water Treatment Equipment

Litchi / Pulp Juice Filling Machine High Capacity Semi- Automatic CE Certificate

High Capacity Carbonated Drink Production Line Machine For 500ml-2500ml Bottle

3 In 1 Plastic Bottle Beverage Filling Machine , Automatic Soft Drink Filling Machine

Red Bull Energy Drink Production Line Automatic For Glass / PET Bottle

Fully Automatic Drinking Water Filling Machine 600-3000BPH For 5 Gallon PET Bottle

Bottled Mineral Drinking Water Production Machine / Filling Production Line

SUS304 PET Bottle Edible Oil Bottle Filling Machine For Non Viscous Liquid Filling

| Name: | Snack Food Processing Line | Model Number: | MT560 |

|---|---|---|---|

| Application: | Popcorn, Co-extruded Cereal Snacks In Shapes Of Pillow,heart, Triangle, Bar; | Voltage: | 3phase/380v/50Hz, Or Designing According To Your Local Power Supply., 3phase/380v/50Hz, Or Designing According To Your Local Power Supply. |

| Capacity: | 120kg/hr, 180kg/hr, 220kg/hr, 220kg/hr | Motor Brand: | SIMENS |

| Material: | Stainless Steel | Certificate: | CE, ISO9001&SGS |

| Power: | 50-170kw Depends On Models And Fuel | Fuel: | Electric, Gas, LPG, Diesel |

| Control System: | PLC |

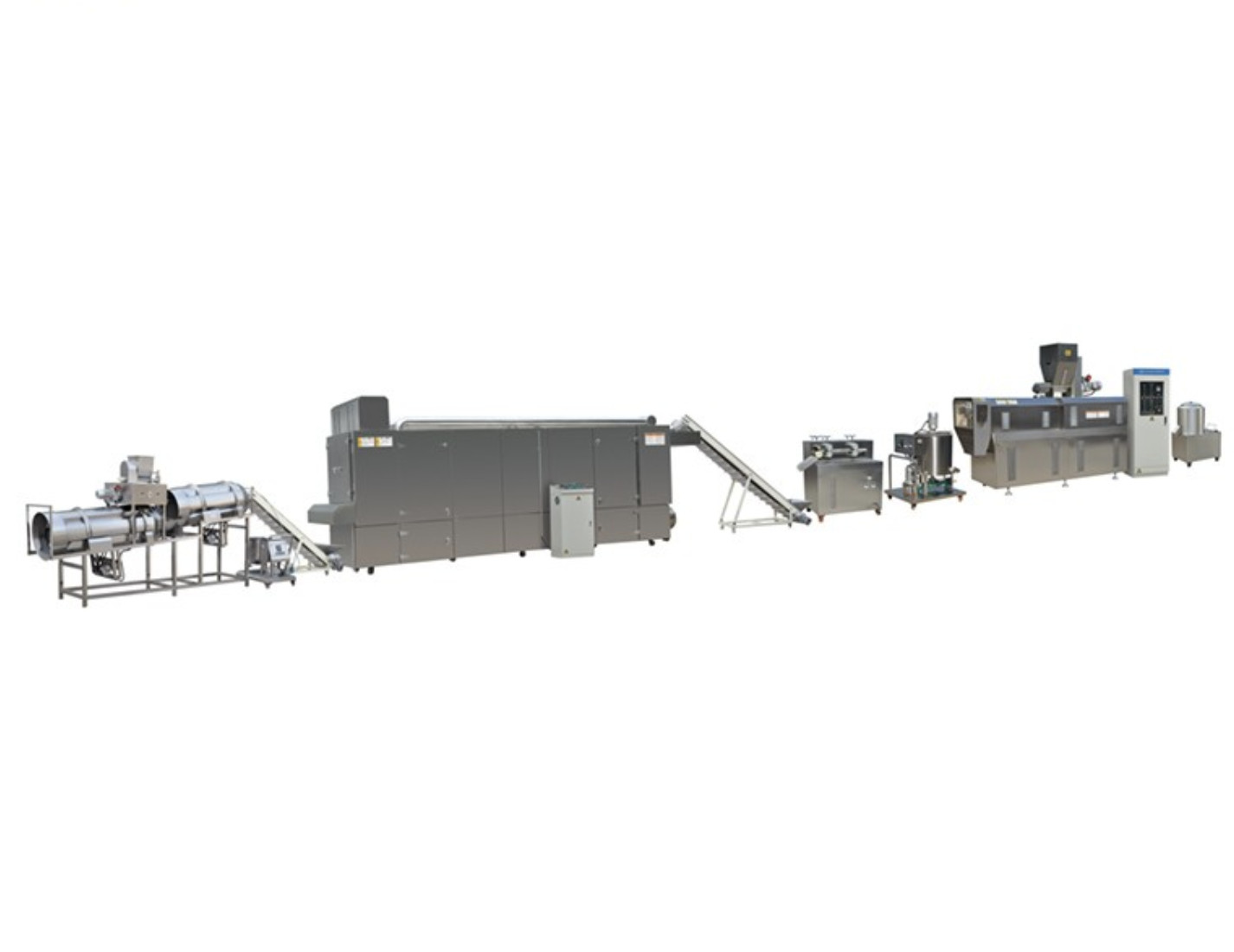

Fully Automatic Chocolate Filled Cereal Snacks Production Line/making machine/process line For Different Shape

1. Production Introduction

With mature of Co-extruded snacks technology, as a machinery industry leading enterprises, we developed the chocolate filled cereal snacks production line as early as 15 years ago, after many times of iteration update, our equipment becomes stable and work efficiently,it can produce a snack with two different flavors,it supports viraous of shapes including pillow, elipse cereal bar,triangle, round cereal bar, triangle cereal bar.

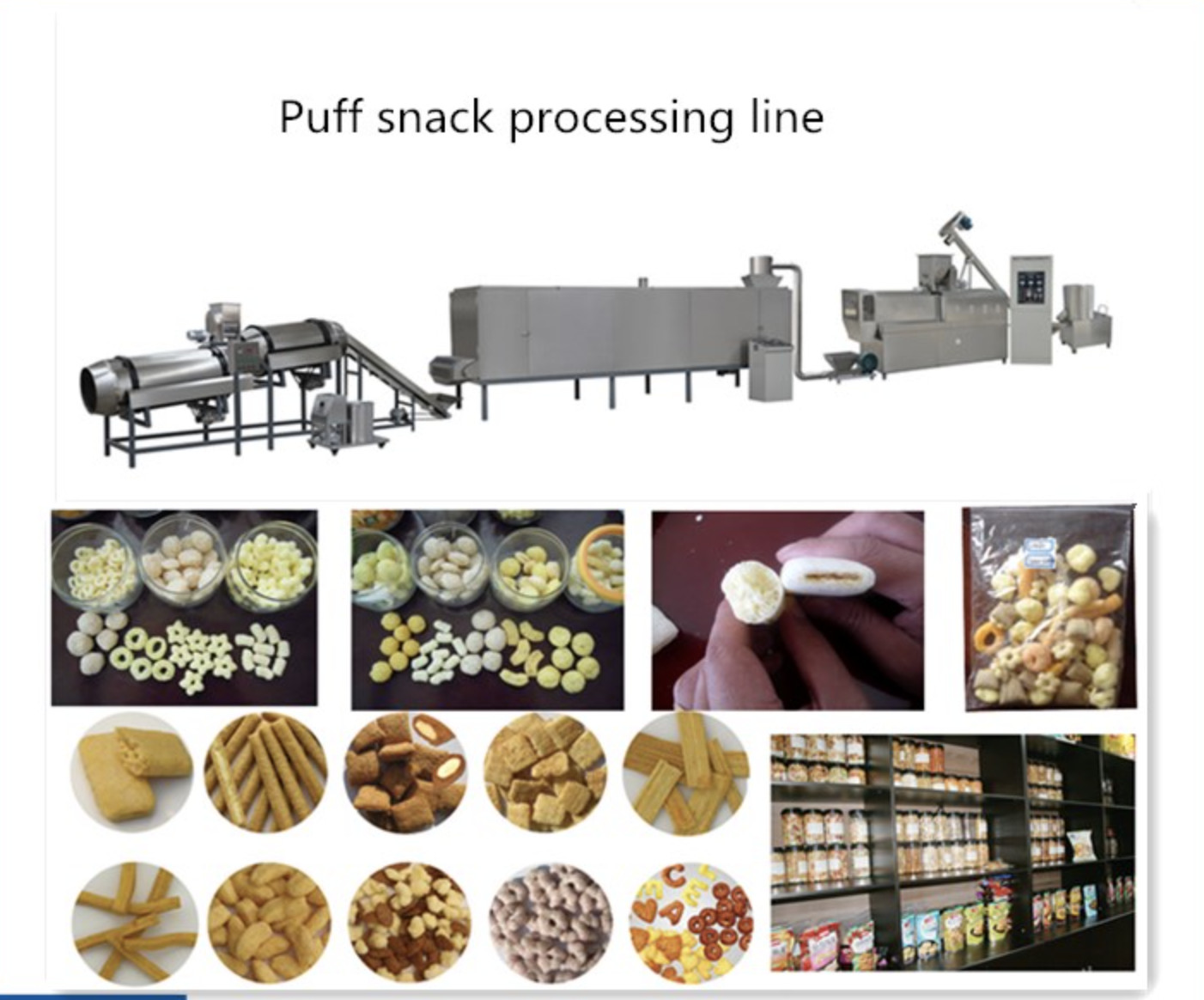

2. Raw Material

Our equipment can make a variety of raw materials into snack food including wheat bran, Corn Grits (Powder), wheat flour,rice flour, oat meal, milk powder, chocolate, coco powder etc.

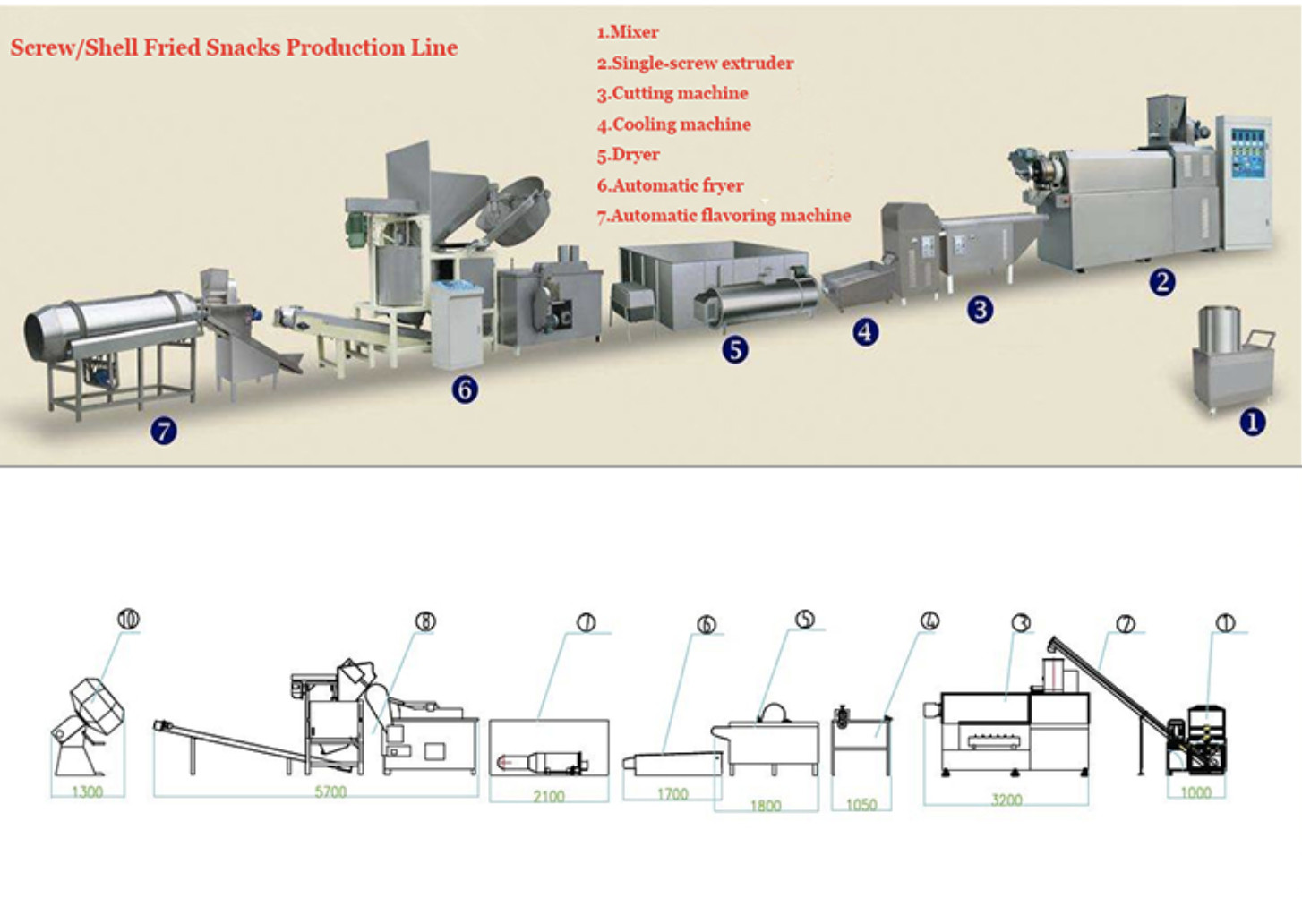

3. Flow Chart

In the past 15 years, we have been solving customer problems. We provide turnkey projects to help customers provide the package design, grinding , production , packing , testing, packaging and delivery programs.

Flour Mixing – Extrusion – Core Filling – Cutting – Drying – Flavoring – Packing

4. We supply various of models to choice according to your demands.

|

NO. |

Extruder Model |

Capacity |

dimension |

|

1 |

MT65 |

120-150kg/hr |

21000x1200x2200mm |

|

2 |

MT65 |

200-250kg/hr |

23000*1500*2200mm |

|

3 |

MT65 |

500-700kg/hr |

28000*3500*4300mm |

|

4 |

MT65 |

800-1000kg/hr |

29500*3500*4300mm |

5. Equipments Components

Flour Mixer | Screw Conveyor | Twin Screw Extruder | Core Filling Machine| Shaping Cutter | Elevating Conveyor | Continuous Belt Dryer | Double Drum Flavoring Machine | Cooling Conveyor

6. Production

a.) Design and test

Our tech engineer has more than 10 years experice in machinery,the machines has developed before 3years, it has been proven to be stable ,all of the machines will be tested over 24 hours continue working,we will send the test report before delivery.

the test case includes function testing,performance testing and high pressure testing,if you would like to know more details about testing we would like to send you more details.

7. Delivery

Machine will be tested strictly beferoe packaged with wooden case,it can be pack according to customers need.

8. Service & Installation

The main goal of our company is to satisfy our customers all over the world,in order to make it we supply free installation oversea, maintenance ,training service .one years' warranty for core sprare parts and cheaper cost for spares after one year,we would like to listen the feedback from our customer to improve our service.

9. Our machine are well-know for international market

we have exported this machine to over 64 countries ,including south american,germanly,Middle east countries ,thailand,africa countries,and etc.

Welcome to inquery,we will make a bussiness proposal accordng to your requirements.

-

Puffed Chocolate Filling Snack Food Production Line With Self Cleaning System

Puffed Chocolate Filling Snack Food Production Line With Self Cleaning System

Our production line has been exported to more than 80 cou...

→ -

Puff Snack Filled Chocolate Production Line Multifunctional Stainless Steel Automatic

Puff Snack Filled Chocolate Production Line Multifunctional Stainless Steel Automatic

Timely updates the machine status for customer to make sure ...

→ -

High Efficiency Snack Food Production Line / Corn Snacks Making Machine

High Efficiency Snack Food Production Line / Corn Snacks Making Machine

Puffed leisuire food production line is used to production p...

→ -

100~500 kg/Hr Snack Food Production Line Chocolate Ball / Chocolate Pillow Filled Puff

100~500 kg/Hr Snack Food Production Line Chocolate Ball / Chocolate Pillow Filled Puff

The main application of this biscuit production line is to p...

→