Live Chat

Click the buttonHigh Speed Carbonated Drink Production Line / Water Bottle Filling Machine

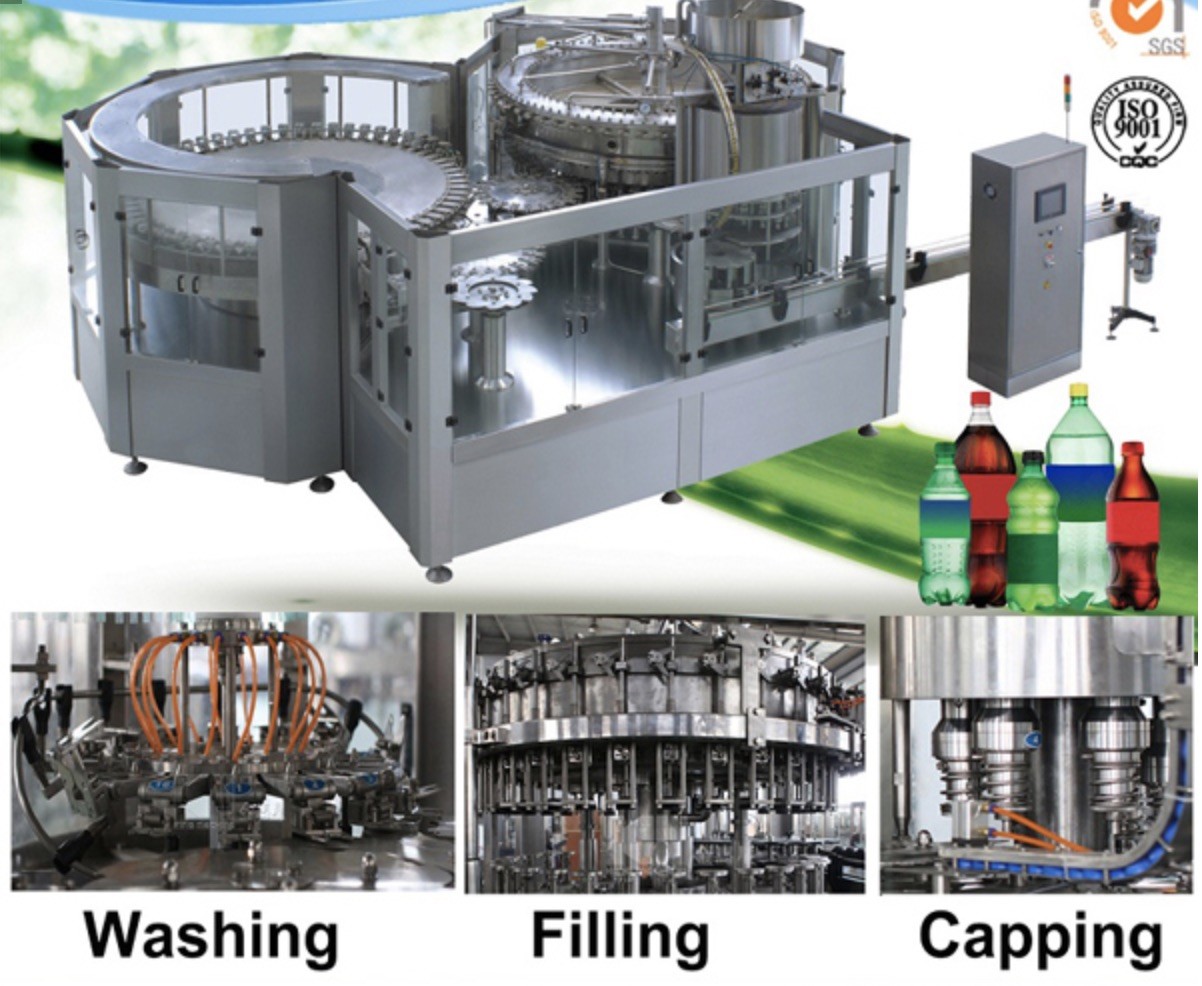

This production line has been developed on the basis of German technology and has international advanced level. It is mainly used for filling gas beverage such as carbonated water, cola, sparkling wine, fruit tea, soda, etc., after making optimization, it has the advanced structure, stable performance, safe operation, high efficiency, easy maintenance, speed can be stepless adjustment, is the ideal choice for small and medium-sized beverage manufacturers

Products

-

Bag Filling Machine

-

Beverage Filling Line

-

Biscuit Making Machine

-

Biscuit Production Line

-

Bottle Blowing Machine

-

Carbonated Drink Production Line

-

Cosmetic Filling Machine

-

Drink Production Line

-

Drinking Water Filling Machine

-

Drinking Water Production Line

-

Edible Oil Production Line

-

Fruit Juice Processing Line

-

Juice Filling Machine

-

Plastic Injection Molding Machine

-

Snack Food Production Line

-

UHT Milk Processing Line

-

Water Treatment Systems

-

Vertical Packaging Machine

-

Other Packaging Machine

-

Pillow Type Packaging Machine

-

Pre-made Pouch Packing Machinery

-

Measuring Equipment

-

Cup Filling Machines

-

Conveyor Equipment

-

Auxiliary Equipment

| Type: | Carbonated Drink Filling Machine | Packaging Type: | Bottles |

|---|---|---|---|

| Automatic Grade: | Automatic | Certification: | CE, ISO2000 |

| Product Name: | Soft Drink Filling Machine | Capacity: | 8000-10000BPH 500ml |

| Degree Of Automation: | Full Auotmatic | Processing Types: | Soft Drink, Carbonated Drink |

| PLC/ Transducer/ Touch Screen: | Siemens | Contactor/ Air Switch/supply: | Schneider |

Fully-automatic Stable High Speed Filling Bottled Carbonated Drink Complete Production Line With CE

Product Description

This production line has been developed on the basis of German technology and has international advanced level. It is mainly used for filling gas beverage such as carbonated water, cola, sparkling wine, fruit tea, soda, etc., after making optimization, it has the advanced structure, stable performance, safe operation, high efficiency, easy maintenance, speed can be stepless adjustment, is the ideal choice for small and medium-sized beverage manufacturers

Product Features

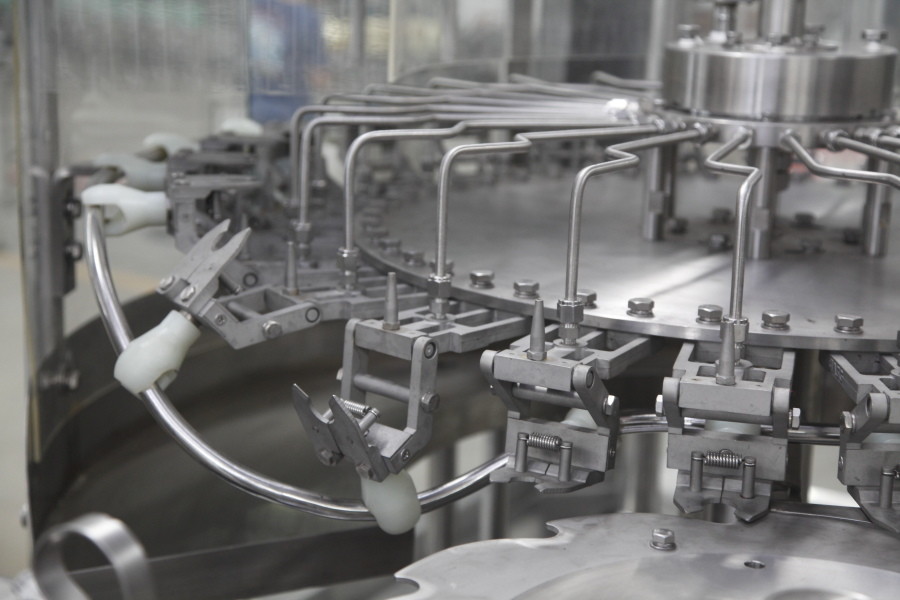

The rotating wheel is a stainless steel welded structure. Our company has CNC machine tools to ensure the quality.

This machine adopts the unique flip bottle holder, the bottle holder holds the bottle neck position, avoids the bottle mouth thread pollution caused by the traditional bottle cap rubber.

The bottle is made of SUS304 stainless steel. It is durable and has no secondary pollution.

The high efficiency atomizing spray is installed in the bottle holder to clean any part of the inner wall of the bottle and can be cleaned.

All the sliding sleeve lifting devices use egos (Germany) anti-corrosion and maintenance bearings.

The washing machine is driven by the transmission system on the rack through the gear drive.

The transmission star wheel is made of high quality stainless steel.

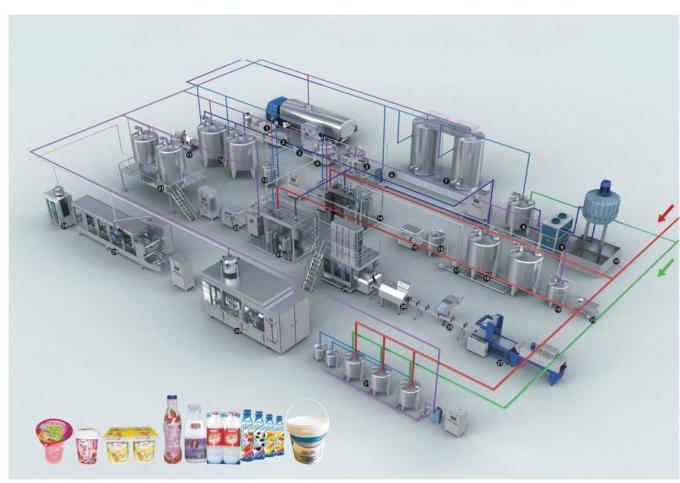

Flow Chart

We are able to supply whole production including water treatment machine, bottle blowing machine and storage tank,filling machine,labelling machne,pe film packaging machine.

Product Sepcifications

| Model : | MT -8 | MT -12 | MT-18 | MT-24 | MT -32 |

| Production Capacity: | 1000-2000b/h | 1000-3000b/h | 2500-4600b/h | 2500-6000b/h | 3500-8000b/h |

| Bottle /standard: | Glass bottle , PVC bottle , Pop-top can | ||||

| Filling Pressure: | 0.2-0.3Mpa | ||||

| Filling Temperature: | 2-6 | ||||

| Power: | 0.75kw | 1.1kw | 1.5kw | 1.5kw | 2.2kw |

| Overall Dimensions: | 1000×900×1800 mm | 1100×1050×1800 mm | 1400×1300×1800 mm | 1600×1540×1800 mm | 1900×1500×2000 mm |

| Weight : | 1000kg | 1600kg | 2100kg | 2700kg | 3500kg |

Product Pictures

OutPut Product

Packaging & delivery

Our Service

- We will provide technical training to customers including equipment structure and maintenance, control and operation. After training, the buyer technician will master the relevant operation and maintenance skills, and can adjust the technology more skillfully, and can handle all kinds of faults in time.

- After the equipment is qualified, the seller will provide one year warranty, one year warranty of the control system, free and spare parts and other spare parts, and shall be priced at the price.

- If the relevant measures cannot solve the problem, the seller will send technicians to the buyer's factory to clean up the on-site faults or related technical problems, and the fees shall be based on the installation and commissioning costs.

- After the warranty period, the seller will provide a wide range of technical support, lifelong service: preferential prices for vulnerable parts and other spare parts.

- Terms: T/T, 30% down payment, and 70% balance before delivery.

- Shipment: 30 working days after receipt of 30% or irrevocable l/c at sight.

- We have a single quality testing and testing department to monitor raw materials, production processes, and standards to ensure product quality.

- Our machines have been sold to more than 30 countries and almost all our customers are satisfied with our machines and our services.

Contact Us

Send you inquery now!we will make a business proposal for you in 12hours!

-

Turnkey Project CSD Carbonated Drink Production Line High Capacity 8000 BPH – 15000 BPH

Turnkey Project CSD Carbonated Drink Production Line High Capacity 8000 BPH – 15000 BPH

Complete CSD carbonated filling line has the 3 function of w...

→ -

High Efficiency Carbonated Drink Production Line Washing Filling And Capping Machine

High Efficiency Carbonated Drink Production Line Washing Filling And Capping Machine

The drinking water filling machine adopts the bottleneck har...

→ -

Pepsi Carbonated Soft Drink Filling Machine , Pet Bottle Soda Filling Machine

Pepsi Carbonated Soft Drink Filling Machine , Pet Bottle Soda Filling Machine

Our company focus on providing carbonated beverage bottle fi...

→ -

2000~18000 BPH Bottle Carbonated Drink Production Line Automatic Rotary

2000~18000 BPH Bottle Carbonated Drink Production Line Automatic Rotary

This machine has the advantages of high reliability, high ef...

→