Live Chat

Click the buttonOrange Juice Processing Machine , Concentrated Pineapple Juice Processing Line

the filter is first filtered by a scraper filter with an aperture of 0.5 millimeters to remove coarse fibers and other impurities. The sieve is used as the 120 purpose horizontal centrifugal filter for fine filtration to remove all suspended solids and easy to precipitate colloidal particles. Material selection, cleaning, cutting, peeling, juice extraction, filtration, degassing, sterilization, cooling, enrichment, and bottling,

Products

-

Bag Filling Machine

-

Beverage Filling Line

-

Biscuit Making Machine

-

Biscuit Production Line

-

Bottle Blowing Machine

-

Carbonated Drink Production Line

-

Cosmetic Filling Machine

-

Drink Production Line

-

Drinking Water Filling Machine

-

Drinking Water Production Line

-

Edible Oil Production Line

-

Fruit Juice Processing Line

-

Juice Filling Machine

-

Plastic Injection Molding Machine

-

Snack Food Production Line

-

UHT Milk Processing Line

-

Water Treatment Systems

-

Vertical Packaging Machine

-

Other Packaging Machine

-

Pillow Type Packaging Machine

-

Pre-made Pouch Packing Machinery

-

Measuring Equipment

-

Cup Filling Machines

-

Conveyor Equipment

-

Auxiliary Equipment

Automatic RO Water Treatment Plant , Stainless Steel Water Treatment Equipment

Litchi / Pulp Juice Filling Machine High Capacity Semi- Automatic CE Certificate

High Capacity Carbonated Drink Production Line Machine For 500ml-2500ml Bottle

3 In 1 Plastic Bottle Beverage Filling Machine , Automatic Soft Drink Filling Machine

Red Bull Energy Drink Production Line Automatic For Glass / PET Bottle

Fully Automatic Drinking Water Filling Machine 600-3000BPH For 5 Gallon PET Bottle

Bottled Mineral Drinking Water Production Machine / Filling Production Line

SUS304 PET Bottle Edible Oil Bottle Filling Machine For Non Viscous Liquid Filling

| Type: | Pineapple Juice Processing Machine | Automatic Grade: | Automatic |

|---|---|---|---|

| Certification: | ISO,CE,SGS | After-sales Service Provided: | Engineers Available To Service Machinery Overseas |

| Machine Material: | SUS304 | Warranty: | 1 Year |

| Bottle Size: | 0.1~25L | Bottle Type: | Round Bottle, Case Bottle ,square Bottle, Flat Bottle |

Trun-key Concentrated Automatic 2T-5T/H Mango, watermelon Juice Processing Line / processing machines

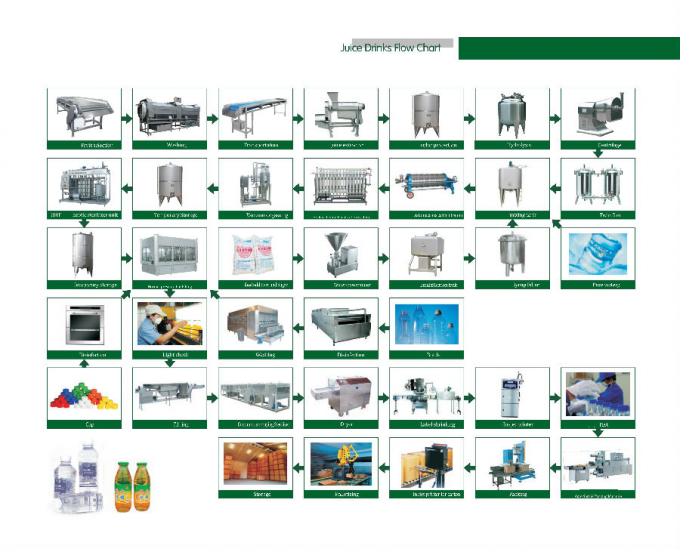

Flow chart:

Material selection, cleaning, cutting, peeling, juice extraction, filtration, degassing, sterilization, cooling, enrichment, and bottling,

2. Key points of operation.

(1) raw material selection: choose two fruit and a small fruit, or produce leftovers from canned fruits and preserved fruits, and make full use of other fruits that can not be processed. Remove the rotted fruit, the disease and the fruit and fruit. The maturity is over 80%.

(2) cleaning, cutting edge, dirt, peel wash cut end surface of the peel, remove the skin.

The pineapple is squeezed in a spiral juicer, and the fruit residue after the first extraction can be added a little more water to increase the juice yield.

(4) the filter is first filtered by a scraper filter with an aperture of 0.5 millimeters to remove coarse fibers and other impurities. The sieve is used as the 120 purpose horizontal centrifugal filter for fine filtration to remove all suspended solids and easy to precipitate colloidal particles.

(5) degassing is degassed under a vacuum of 64~87 kPa, and then the degassed juice is sucked out at the outlet by a screw pump.

(6) sterilization syrup by instant sterilization method. The temperature is (93 + 2) centigrade for 15~30 seconds.

The juice is cooled in the heat exchanger, and the heat exchange between the germicidal juice and the original juice is made, and the germicidal juice is cooled to about 50 C, and the original juice is preheated at the same time.

(7) the juice is cooled in the heat exchanger.

The concentration of sodium benzoate is added to the juice of 0.5 grams per kilogram, and is concentrated in the vacuum thickener. The vacuum degree is controlled at about 85 thousand PA, the temperature is 48~55 C, and the steam pressure is 50~150 kPa at the temperature of

8). When the total sugar content is up to 57.5% to 60% (converted sugar meter), the pot is ready.

(9) prior to bottling bottling bottle and other containers for cleaning and disinfection. When the fruit juice is cooled to the temperature that the bottle can bear, it is bottled and sealed in the sterile room, removing the moisture outside the bottle, labeling and storing it. 3. quality standard

The fruit juice has a semitransparent light yellow to brown yellow, and after 6 times the diluted fruit juice, it has a similar fragrance to pineapple juice, without a bitter taste and no odor.

The total acidity (2) reached 57.5% to 60%, the total acidity (with crystal citric acid) was above 31%, the content of sodium benzoate was not more than 0.1%, the content of heavy metals was less than 3 mg / kg, copper less than 10 mg / kg, and tin less than 200 mg / kg.

Main Equipments:

Water treatment equipment :

Sand stick filter, filter, ion hole

Membrane filter, filter, diatomite

Filter, manganese sand filter

Mixed than machine (homogenizer):

With the material tank, tank ingredients

Pipeline equipment cleaning and disinfection facilities.

1, pipeline cleaning machine recoil

2, chlorine dioxide disinfection equipment

Bottle (cover) * disinfection tank cap

1, immersion disinfection pool

2, automatic bottle washing disinfection machine

Aseptic canning machine

automatic filling and capping machine

1 Automatic washing machine,

2 bottles of disinfection

3. Automatic bottle punching machine

Light inspection

Specification:

| production | Various fruit juice,concentrate,juice powder |

| Capacity | 2T/D–50T/D |

| Endproduct package | bottle,Tin, plastic bag |

| Run | Stable |

| voltage | 220V/380V |

| certification | CE ISO |

| Project | Turn-key Project |

Product Show:

Output Product

-

Small Scale Fruit Juice Processing Line / Tea Manufacturing Equipment SUS304

Small Scale Fruit Juice Processing Line / Tea Manufacturing Equipment SUS304

The juice production line is mainly used for beverage juice ...

→ -

Commercial Fruit Juice Production Equipment ,12000 BPH Fruit Juice Manufacturing Plant

Commercial Fruit Juice Production Equipment ,12000 BPH Fruit Juice Manufacturing Plant

The machine is used for juicing, tea and other non-air drink...

→ -

High Efficiency Orange Juice Production Line , Fruit Juice Processing Equipment

High Efficiency Orange Juice Production Line , Fruit Juice Processing Equipment

This RCGF Washing-filling-capping 3-in-1unit: China orange j...

→ -

SUS304 Fruit Juice Processing Line Turnkey Project For Tomato Apple Strawberry

SUS304 Fruit Juice Processing Line Turnkey Project For Tomato Apple Strawberry

the product after filter filter is driven into the steriliza...

→