Live Chat

Click the buttonPLC Controlled Carbonated Drink Production Line / Carbonated Soda Filling Machine

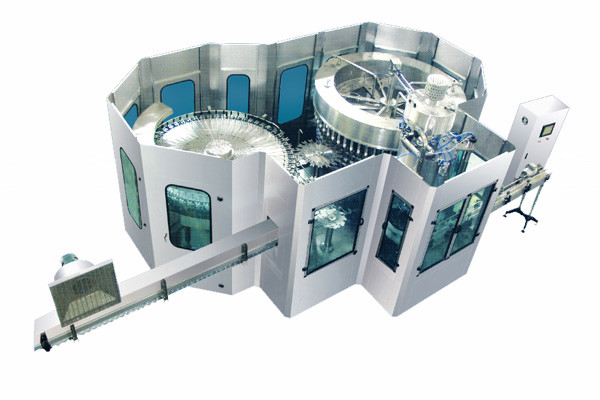

THis CGF washing and filling cover 3-in-1unit: beverage machinery is used to contain gas drinks, including cola, fanta, aerated soda and so on. Washing filling capping unit: 3 – in – 1 beverage machine can complete all the process such as washing, filling and sealing, it can reduce the time of the contact materials and the outside world, improve health conditions, production capacity and economic benefits.

Products

-

Bag Filling Machine

-

Beverage Filling Line

-

Biscuit Making Machine

-

Biscuit Production Line

-

Bottle Blowing Machine

-

Carbonated Drink Production Line

-

Cosmetic Filling Machine

-

Drink Production Line

-

Drinking Water Filling Machine

-

Drinking Water Production Line

-

Edible Oil Production Line

-

Fruit Juice Processing Line

-

Juice Filling Machine

-

Plastic Injection Molding Machine

-

Snack Food Production Line

-

UHT Milk Processing Line

-

Water Treatment Systems

-

Vertical Packaging Machine

-

Other Packaging Machine

-

Pillow Type Packaging Machine

-

Pre-made Pouch Packing Machinery

-

Measuring Equipment

-

Cup Filling Machines

-

Conveyor Equipment

-

Auxiliary Equipment

Automatic RO Water Treatment Plant , Stainless Steel Water Treatment Equipment

Litchi / Pulp Juice Filling Machine High Capacity Semi- Automatic CE Certificate

High Capacity Carbonated Drink Production Line Machine For 500ml-2500ml Bottle

3 In 1 Plastic Bottle Beverage Filling Machine , Automatic Soft Drink Filling Machine

Red Bull Energy Drink Production Line Automatic For Glass / PET Bottle

Fully Automatic Drinking Water Filling Machine 600-3000BPH For 5 Gallon PET Bottle

Bottled Mineral Drinking Water Production Machine / Filling Production Line

SUS304 PET Bottle Edible Oil Bottle Filling Machine For Non Viscous Liquid Filling

| Type: | Carbonated Soft Drink Production Line | Condition: | New |

|---|---|---|---|

| Packaging Type: | Bottles | Automatic Grade: | Automatic |

| After-sales Service Provided: | Engineers Available To Service Machinery Overseas | Product Name: | Soft Drink Filling Machine |

| Capacity: | 8000-10000BPH 500ml | PLC/ Transducer/ Touch Screen: | Siemens |

PLC Controlled Automatic Carbonated Soft Drinks (CSD) Small Bottle Drink production line commercial

Product Description

THis CGF washing and filling cover 3-in-1unit: beverage machinery is used to contain gas drinks, including cola, fanta, aerated soda and so on. Washing filling capping unit: 3 – in – 1 beverage machine can complete all the process such as washing, filling and sealing, it can reduce the time of the contact materials and the outside world, improve health conditions, production capacity and economic benefits.

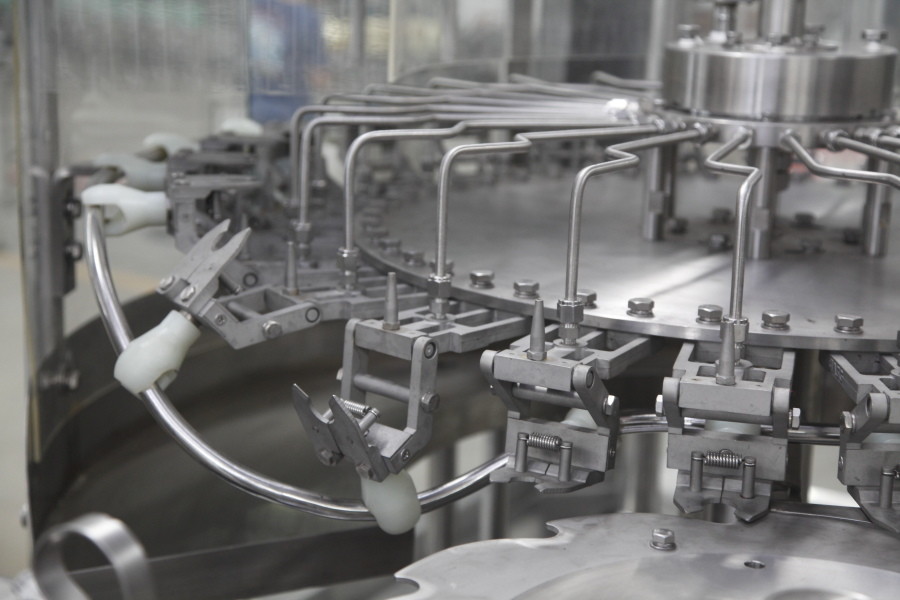

Product Advantage

- 304 stainless steel wash head, water injection design, save water and clean.

- 304 stainless steel clamp and plastic pad ensure minimum bottle collision during cleaning.

- Figure 304 stainless steel washing pump

- Filling part of bottled mineral water filling machine:

- High precision filling nozzle, PLC variable signal control, ensure filling accuracy is high, filling and stabilizing stable.

- FILLING volume can be ranked well, same liquid level after filling.

- All 304 stainless steel contact parts and liquid tank, fine polishing, no dead angle, easy to clean.

- 304 stainless steel filling pump

- No bottle and no filling

- The sealing part of bottled mineral water filling machine:

- The electromagnetic L system, with head cover, unloading function, to ensure the minimum bottle capping process damage

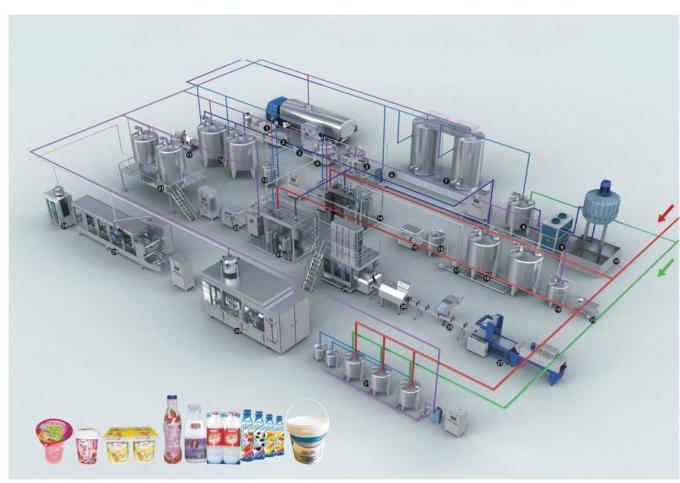

Flow Chart

We are able to supply whole production including :

Water treatment system

– Blow molding machine

– CSD preparation and mixing system

– Bottle unscrambler/Manual bottle loading system

– Air conveyor

– Rinsing-filling-capping 3-in-1 monoblock

– Bottle Warmer

– Labeling Machine

– Water Blow Drier,

– Lampinspection,

– Code ink jetter

– Shrink wrapper / carton packaging machine

– Palletizing system

– Conveying System

Product Sepcifications

| Model MT-C series | 12-12-5 | 14-14-5 | 24-24-8 | 32-32-10 | 40-40-10 | 50-50-12 | ||

| Washing-Filling-Capping | 12-12-5 | 14-14-5 | 24-24-8 | 32-32-10 | 40-40-10 | 50-50-12 | ||

|

Producing capacity (600ml) |

2000-4000 (bph) |

5000-7000 (bph) |

8000-12000 (bph) |

12000-15000 (bph) |

14000-20000 (bph) |

20000-24000 (bph) |

||

| Applicable bottle (mm) | φ=50-108 H=170-340 330ml-2.25L | |||||||

| Pressure (kg/cm2) | 2~3 | |||||||

|

Outside vacuum

pump power (kw) |

Main motor 1.5kw |

Main motor 2.2kw |

Main motor 3kw |

Main motor 4kw |

Main motor 7.5kw |

Main motor 9.5kw |

||

|

Overall dimension (mm)

(LxWxH) |

2100×1200 x2500 |

2460×1720 x2650 |

3100×2100 x2650 |

3500×2500 x2650 |

4600×1800 x2650 |

5200×4500 x3400 |

||

| Weight(kg) | 2500 | 3500 | 4200 | 5500 | 6800 | 7600 | ||

We could costomize the machine according to your need, contact us for more details.

Product Pictures

Our Machine VS others

OutPut Product

Packaging & delivery

Our Service

- We will reply to your inquiry within 12 hours.

- We can help you design product lines, workshops and provide turnkey projects.

- Free equipment installation and debugging.

- The whole system is guaranteed for two years.

- You and our business relationship will be confidential to any third party.

- Free production technology and process configuration.

- We can provide internship service to help you train operators and technicians.

- After two years, we can help you to repair the machine and accessories.

- Both the OEM and ODM projects are available.

- Working hours: Monday to Saturday 10:00 am – (UTC + 8).

- we have good after-sales team for your problem. If you have any questions, please reply in time.

Contact Us

Send you inquery now!we will make a business proposal for you in 12hours!

-

High Capacity Carbonated Drink Production Line Machine For 500ml-2500ml Bottle

High Capacity Carbonated Drink Production Line Machine For 500ml-2500ml Bottle

This machine is mainly used for filling carbonated drinks. I...

→ -

High Speed Carbonated Drink Production Line / Water Bottle Filling Machine

High Speed Carbonated Drink Production Line / Water Bottle Filling Machine

This production line has been developed on the basis of G...

→ -

Small Scale Soda Bottling Equipment , Carbonated Soft Drink Production Line Glass Bottle

Small Scale Soda Bottling Equipment , Carbonated Soft Drink Production Line Glass Bottle

The whole machine adopts PLC computer program control and ma...

→ -

Industrial Carbonated Drink Production Line 200ml – 2000ml Bottle For Soft Drink

Industrial Carbonated Drink Production Line 200ml – 2000ml Bottle For Soft Drink

The machine developed by my company independent, the core t...

→