Live Chat

Click the buttonSmall Capacity Cosmetic Filling Machine Plastic / Aluminum Tube Filling And Sealing Machine

this filling sealing machine is suitable for all kinds of paste, viscous fluid and filling material, including plastic, laminated tube, heating tube, seal batch number or production date. It is widely used in pharmacy, food, cosmetics, daily chemical industry.normal speed is 40 ~ 100 pieces/minute.

Products

-

Bag Filling Machine

-

Beverage Filling Line

-

Biscuit Making Machine

-

Biscuit Production Line

-

Bottle Blowing Machine

-

Carbonated Drink Production Line

-

Cosmetic Filling Machine

-

Drink Production Line

-

Drinking Water Filling Machine

-

Drinking Water Production Line

-

Edible Oil Production Line

-

Fruit Juice Processing Line

-

Juice Filling Machine

-

Plastic Injection Molding Machine

-

Snack Food Production Line

-

UHT Milk Processing Line

-

Water Treatment Systems

-

Vertical Packaging Machine

-

Other Packaging Machine

-

Pillow Type Packaging Machine

-

Pre-made Pouch Packing Machinery

-

Measuring Equipment

-

Cup Filling Machines

-

Conveyor Equipment

-

Auxiliary Equipment

Automatic RO Water Treatment Plant , Stainless Steel Water Treatment Equipment

Litchi / Pulp Juice Filling Machine High Capacity Semi- Automatic CE Certificate

High Capacity Carbonated Drink Production Line Machine For 500ml-2500ml Bottle

3 In 1 Plastic Bottle Beverage Filling Machine , Automatic Soft Drink Filling Machine

Red Bull Energy Drink Production Line Automatic For Glass / PET Bottle

Fully Automatic Drinking Water Filling Machine 600-3000BPH For 5 Gallon PET Bottle

Bottled Mineral Drinking Water Production Machine / Filling Production Line

SUS304 PET Bottle Edible Oil Bottle Filling Machine For Non Viscous Liquid Filling

| Type: | Plastic Tube Filling And Sealing Machine | Application: | Chemical, Medical |

|---|---|---|---|

| Packaging Type: | Bottles | Automatic Grade: | Automatic |

| Driven Type: | Electric | Voltage: | Can Be Customizde |

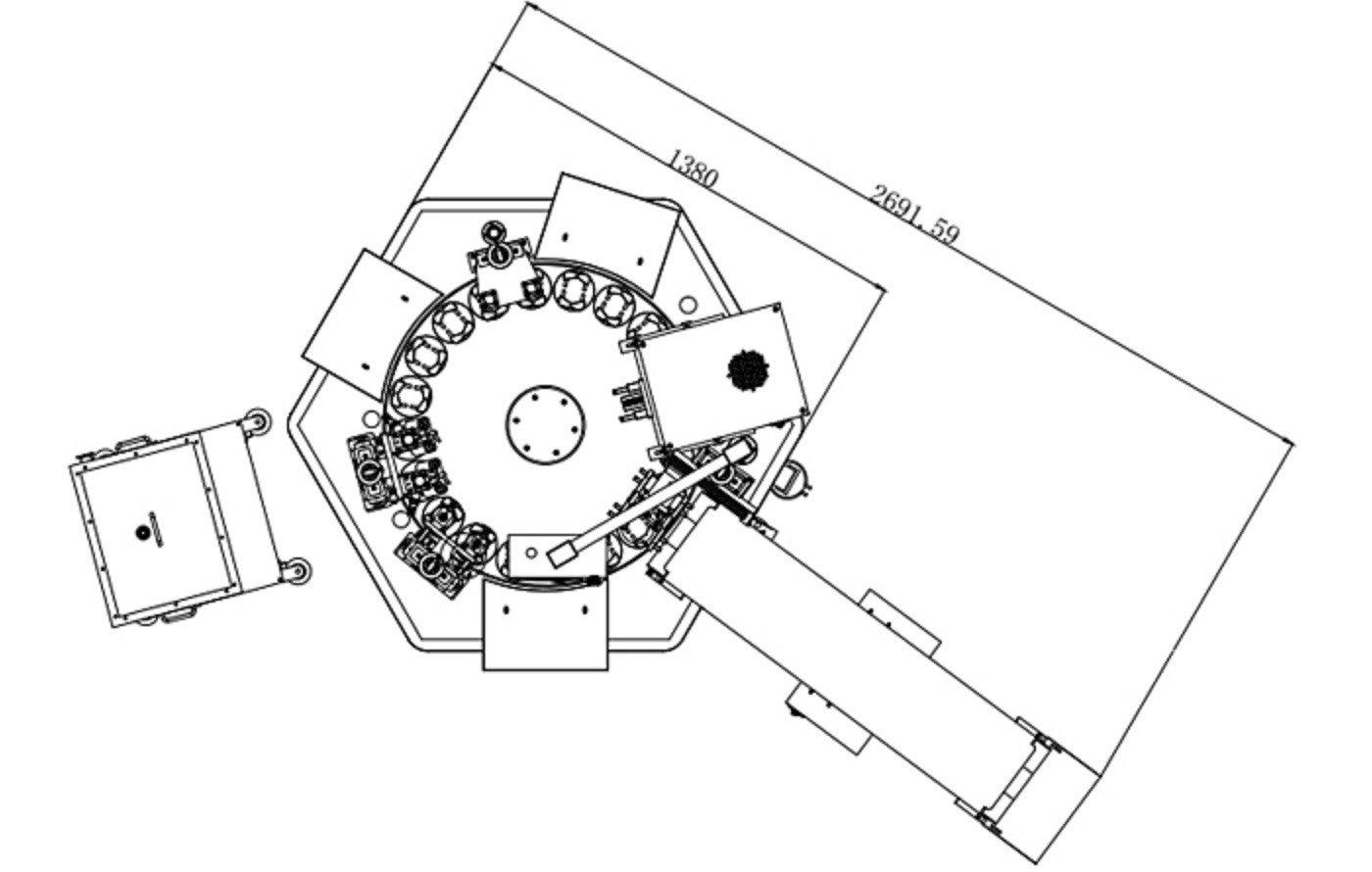

| Brand Name: | UNIMACH | Dimension(L*W*H): | 1800*800*1400mm |

| Weight: | 750KG | Certification: | ISO,GMP |

5-250ml Small Capcity Cosmetic tooth paste plastic aluminum tube filling sealing machine

The original Swiss LEISTER heater USES a more stable and reliable seal.

The filling head does not decrease, leakage, rising bubbles and overflow

No pipe and no stuffing, prevent material waste.

Product Summary:

this filling sealing machine is suitable for all kinds of paste, viscous fluid and filling material, including plastic, laminated tube, heating tube, seal batch number or production date. It is widely used in pharmacy, food, cosmetics, daily chemical industry.normal speed is 40 ~ 100 pieces/minute.

Features:

- High viscosity material has automatic control and mild batching system (optional).

- Nitrogen injection function (optional)

- The machine stops automatically when the setting is complete.

- The automatic detection tube is inverted, and the photoelectric sensor can detect the inverted tube accurately.

- All 6 processes, from spreading roller, bottle forming, filling, sealing end, printing serial number, cutting end, cutting, control programming.

- The machine is divided into famous brands, lubricating oil maintenance, no noise, no pollution.

- High quality CAM is used for indexing.

- Remove film, plastic bottle molding, filling, date printing, sealing and cutting can be completed automatically. Save cost and time.

- The machine is a stepless variable frequency speed regulating system. The filling speed can be easily set.

- This machine is configured with overload protection Settings.

- Easy to adjust, can fill multiple pipes on the same machine.

- Water cooler (chiller). (optional)

- All parts of the filling machine are assembled with quick joints for easy cleaning and disinfection.

- When the door is opened, the machine is closed and the filling can only be carried out by pipe.

- PLC and touch screen combination of automatic control system. Electrical brand customization.

- Main pneumatic components and wiring are imported accessories.

- Intelligent temperature control cooling system, sealing more reliable.

- All made of high quality stainless steel, meet the standard GMP requirement.

- The air supply system is installed on the filling nozzle, cutting material and not dripping.

- The computer interface operation is simple and clear.

- Some contact materials are made of 316L stainless steel, clean and hygienic, conforming to GMP standard.

- PLC control, frequency conversion speed control.

- The feed pump. Shampoo, cream and honey (

- The machine is designed to connect the automatic feeding system to the emulsifier or mixer, which facilitates the overload protection.

Specifications

|

Model

|

60A

|

|

Power Supply

|

220V/380V 50Hz/60Hz

|

|

Power Rate

|

4.5KW (9.5KW with hopper heating)

|

|

Air pressure

|

0.6-0.7MPa

|

|

Filling Range

|

5-250ml

|

|

Filling Precision

|

≤±1℅

|

|

Filling capacity

|

40-60pcs/min

|

|

Tube Diameter

|

ф13-ф50mm

|

|

Dimension

|

1900mm×1000mm×1800mm

|

|

Weight

|

800kg

|

Machine Show

For more Details pls contact us .we will send you videos and pictures.

Samples:

-

Automatic / Manual Cosmetic Filling Machine For Cosmetic Creams / Lotions

Automatic / Manual Cosmetic Filling Machine For Cosmetic Creams / Lotions

The machine integrates air cleaning - filling - sealing syst...

→ -

Stainless Steel Cosmetic Filling Machine / Automatic Lotion Filling Machine

Stainless Steel Cosmetic Filling Machine / Automatic Lotion Filling Machine

We promise, within a year, if the spare parts is damaged, th...

→ -

Toothpaste / Plastic Tube Sealing Machine , Cosmetic Tube Filling Sealing Machine

Toothpaste / Plastic Tube Sealing Machine , Cosmetic Tube Filling Sealing Machine

The machine is used for automatically filling and sealing cr...

→ -

25-250 ml Cosmetic Filling Machine / Automatic Tube Filling And Sealing Machine

25-250 ml Cosmetic Filling Machine / Automatic Tube Filling And Sealing Machine

The power source of ultrasonic sealing machine is pneumatic,...

→