Live Chat

Click the buttonPuffed Chocolate Filling Snack Food Production Line With Self Cleaning System

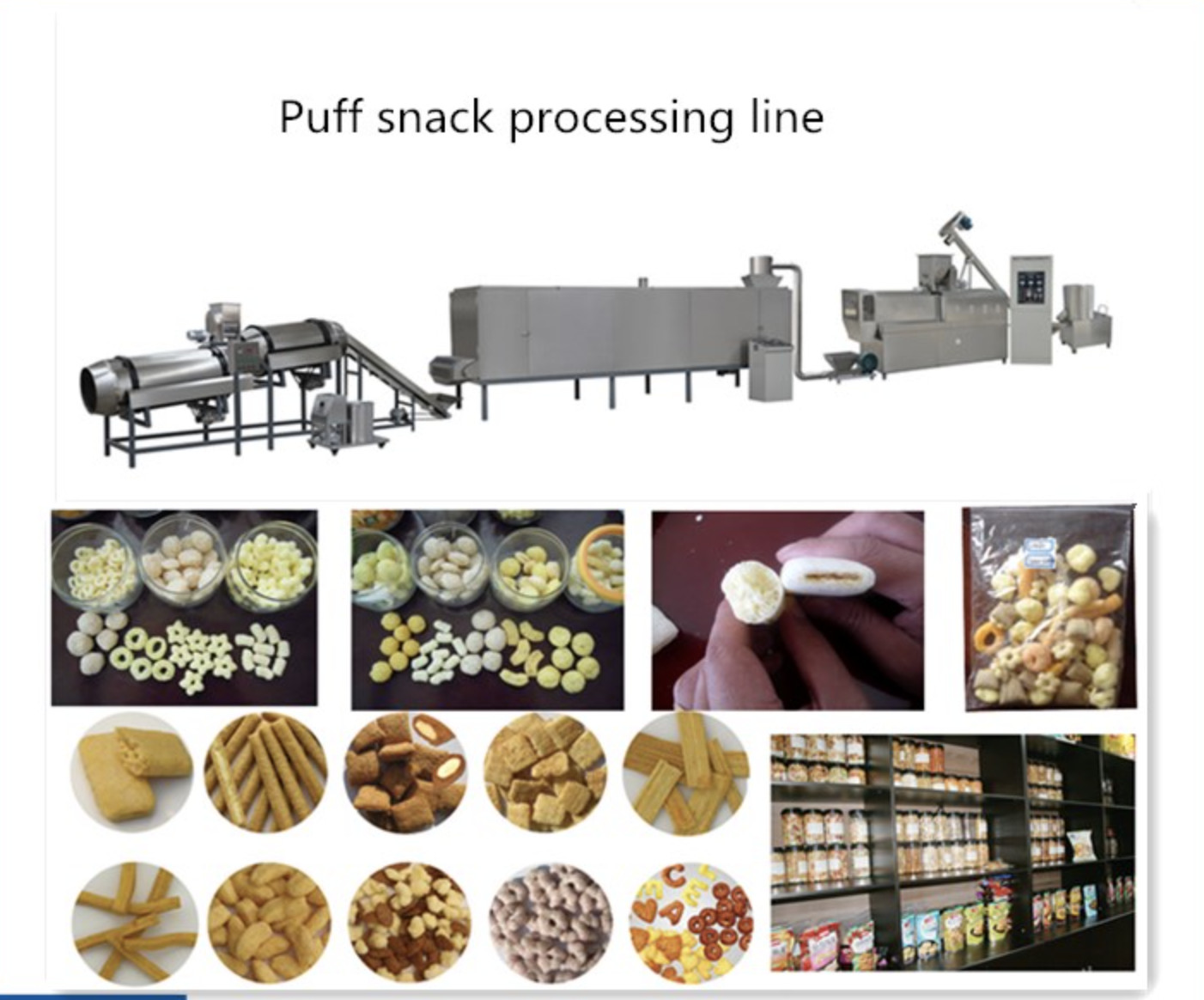

Our production line has been exported to more than 80 countries all over the world, we also have some business parter in these countries. we will insistantly delivery valable products for international market. Mixing,exgrudering, core filling and packaging for various shapes snack food with corn flour,wheat flour and ogher grain flour.

Products

-

Bag Filling Machine

-

Beverage Filling Line

-

Biscuit Making Machine

-

Biscuit Production Line

-

Bottle Blowing Machine

-

Carbonated Drink Production Line

-

Cosmetic Filling Machine

-

Drink Production Line

-

Drinking Water Filling Machine

-

Drinking Water Production Line

-

Edible Oil Production Line

-

Fruit Juice Processing Line

-

Juice Filling Machine

-

Plastic Injection Molding Machine

-

Snack Food Production Line

-

UHT Milk Processing Line

-

Water Treatment Systems

-

Vertical Packaging Machine

-

Other Packaging Machine

-

Pillow Type Packaging Machine

-

Pre-made Pouch Packing Machinery

-

Measuring Equipment

-

Cup Filling Machines

-

Conveyor Equipment

-

Auxiliary Equipment

Automatic RO Water Treatment Plant , Stainless Steel Water Treatment Equipment

Litchi / Pulp Juice Filling Machine High Capacity Semi- Automatic CE Certificate

High Capacity Carbonated Drink Production Line Machine For 500ml-2500ml Bottle

3 In 1 Plastic Bottle Beverage Filling Machine , Automatic Soft Drink Filling Machine

Red Bull Energy Drink Production Line Automatic For Glass / PET Bottle

Fully Automatic Drinking Water Filling Machine 600-3000BPH For 5 Gallon PET Bottle

Bottled Mineral Drinking Water Production Machine / Filling Production Line

SUS304 PET Bottle Edible Oil Bottle Filling Machine For Non Viscous Liquid Filling

| Brand Name: | Qualipak | Model Number: | MT760 |

|---|---|---|---|

| Application: | Puffed Chocolate Filling Snacks Making | Voltage: | 380V/220V Or Designing According To Requirement |

| Power(W): | 53kw,76kw,117kw | Weight: | 3-10 Tons |

| Dimension(L*W*H): | 21000x1200x2200mm/23000x1500x2200mm/28000x3500x4300mm | Products: | Puffed Chocolate Filling Snacks Making Machine/production Line |

| Capacity: | 120-150kg/h, 200-250kg/h, 400-500kg/h | Motor: | Siemens |

| Installed Power: | 53kw | Main Drive Power: | 37kw |

| Inverter: | Delta | Electrical Part: | FUJI,Omron,Siemens,Mitsubishi,LG |

| Relay: | Omron | Baking Fuel: | Electricity/gas/diesel |

| Machine Material: | Stainless Steel |

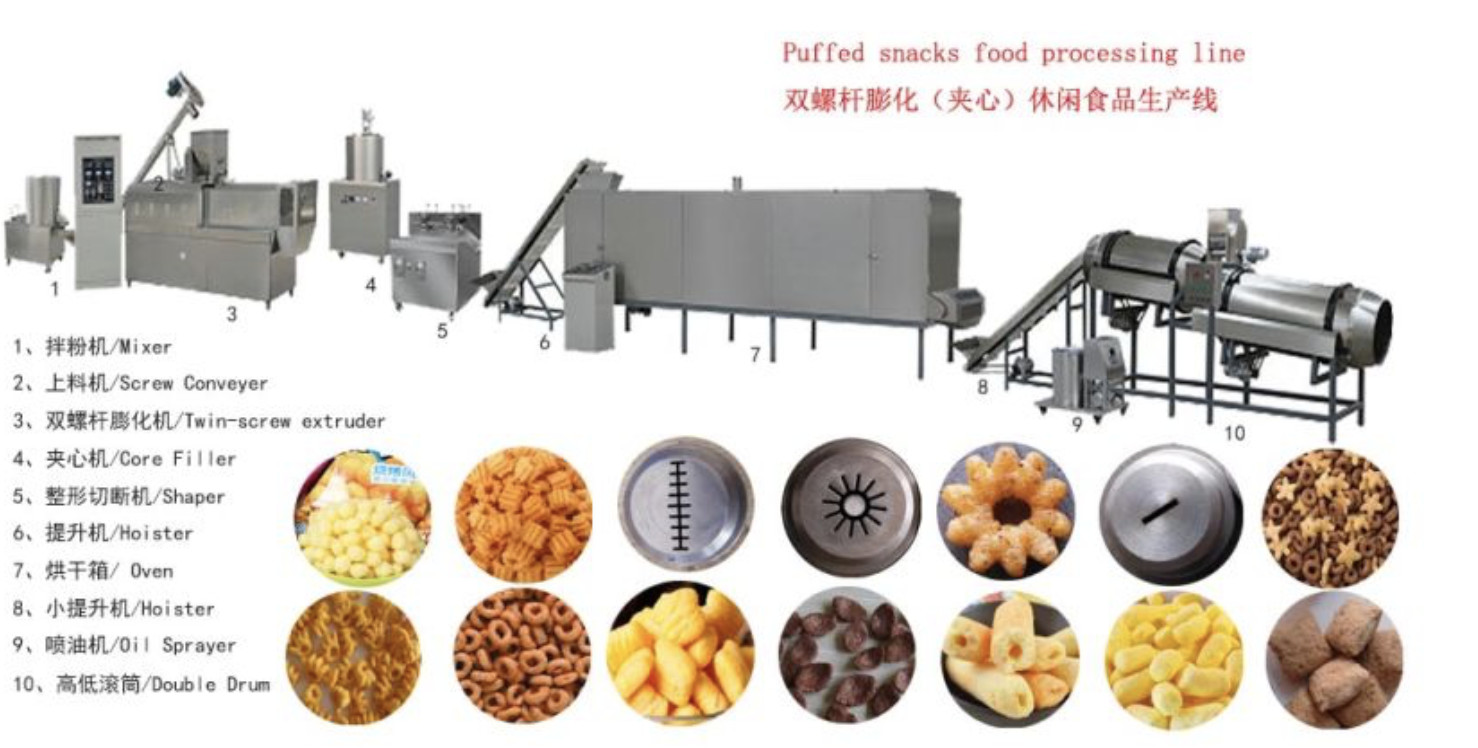

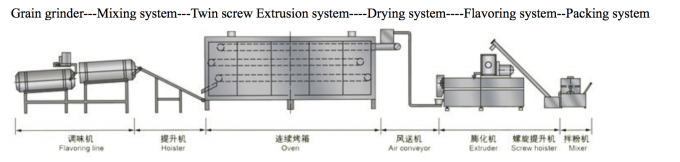

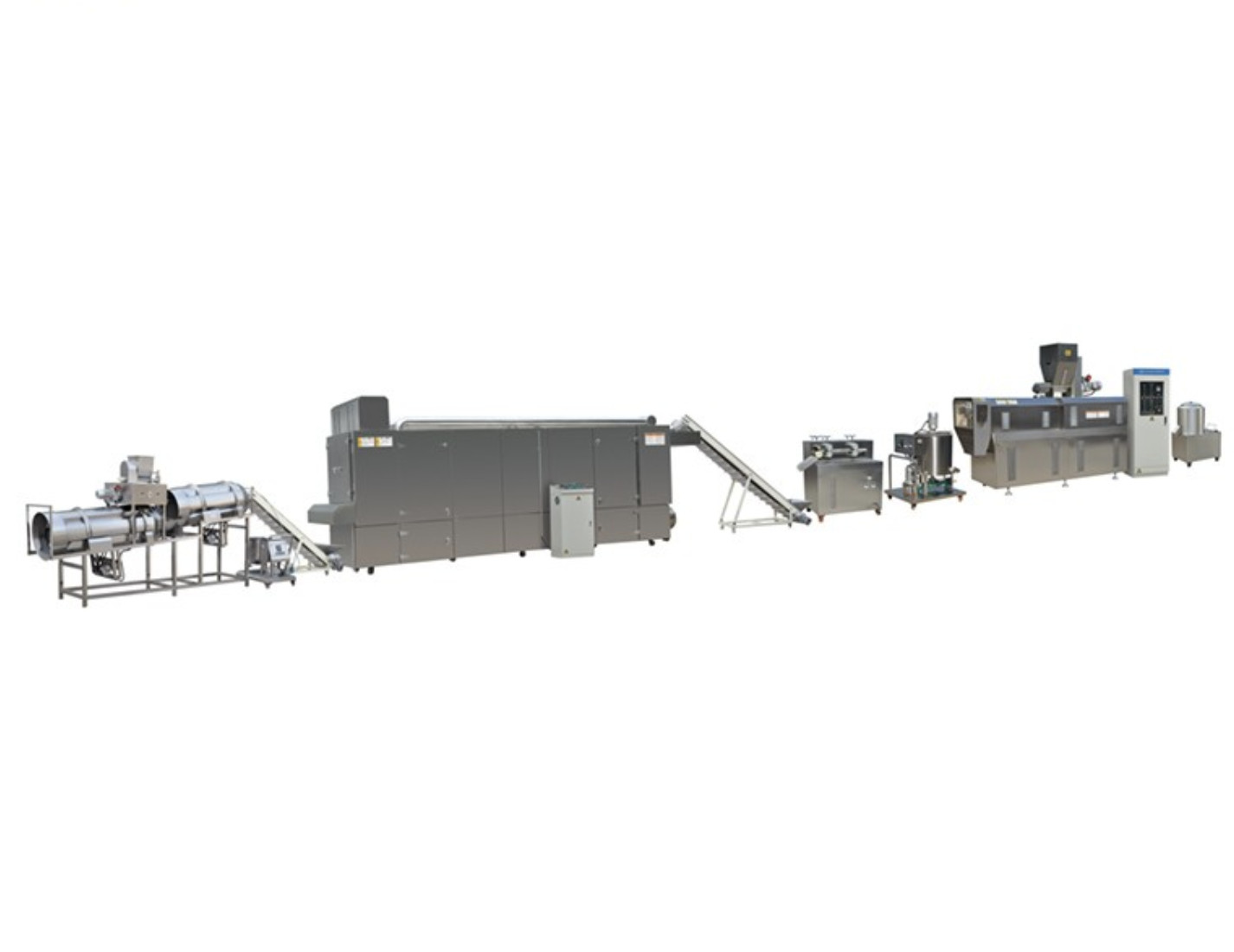

Advanced design Puffed chocolate filling snacks making machine production line with self-cleaning system

Main application:

Machine features And Advangtage

- Famous international brand core part equipped in machine ,like Siemens main motor, which ensure that machine works stable and efficient.

- Intelligent design with automatic adopting speed adjusted converter on feeding, extrusion and cutting, which reduce the power consumption for running cost.

- Considerate design with self-cleaning system, you don't no need to discharge and clean the barrel to reduce the cost of maintenance.

- Alloy (38CrMoAL) screw is made with nitriding process, which is high strength and wear resting.

- Food grade stainless steel twin screw feeding machine,no seconday pollution.

- Stable materials feeding, no secondary pollution for snack food.

- Advanced design with automatic lubrication function in gearbox, which makes gear working durable than normal ones.

- Safety extruding with Increased radiator on driving part for forced cooling effect.

|

Model

|

Installed Power

|

main motor Power

|

Output

|

Size

|

|

MT65

|

34kw

|

22kw

|

120-156kg/h

|

2350x900x1850mm

|

|

MT65L

|

45kw

|

30kw

|

190kg/h

|

3200x950x1850mm

|

|

MT70

|

53kw

|

37kw

|

200-260kg/h

|

3200x760x2000mm

|

|

MT70L

|

54kw

|

37kw

|

200-260kg/h

|

3100x760x2000mm

|

|

MT85

|

89kw

|

75kw

|

500-800kg/h

|

3300 x1100x2350mm

|

|

MT85A

|

121kw

|

90kw

|

800-1200kg/h

|

3500 x1100x2350mm

|

- Free Consultation before sales.

- Free business plan desgin/

- Free Debugging of equipment before pack

- Monitor the whole process of production.

- Delivery on time to meet the time requirement.

- Free Training of equipment maintenance and operating personally;

- Provide Machines with New production techniques and formulas;

- Provide 1 year complete warranty and life-time maintenance service.

9.Our reputation

-

High Efficiency Snack Food Production Line / Corn Snacks Making Machine

High Efficiency Snack Food Production Line / Corn Snacks Making Machine

Puffed leisuire food production line is used to production p...

→ -

Chocolate Filled Cereal Snack Food Processing Equipment For Different Shape

Chocolate Filled Cereal Snack Food Processing Equipment For Different Shape

With mature of Co-extruded snacks technology, as a machinery...

→ -

100~500 kg/Hr Snack Food Production Line Chocolate Ball / Chocolate Pillow Filled Puff

100~500 kg/Hr Snack Food Production Line Chocolate Ball / Chocolate Pillow Filled Puff

The main application of this biscuit production line is to p...

→ -

Mini Chocolate Core Filled Snack Food Processing Line Small Capacity High Performance

Mini Chocolate Core Filled Snack Food Processing Line Small Capacity High Performance

The machine are made of food-grade stainless steel, he scre...

→