Live Chat

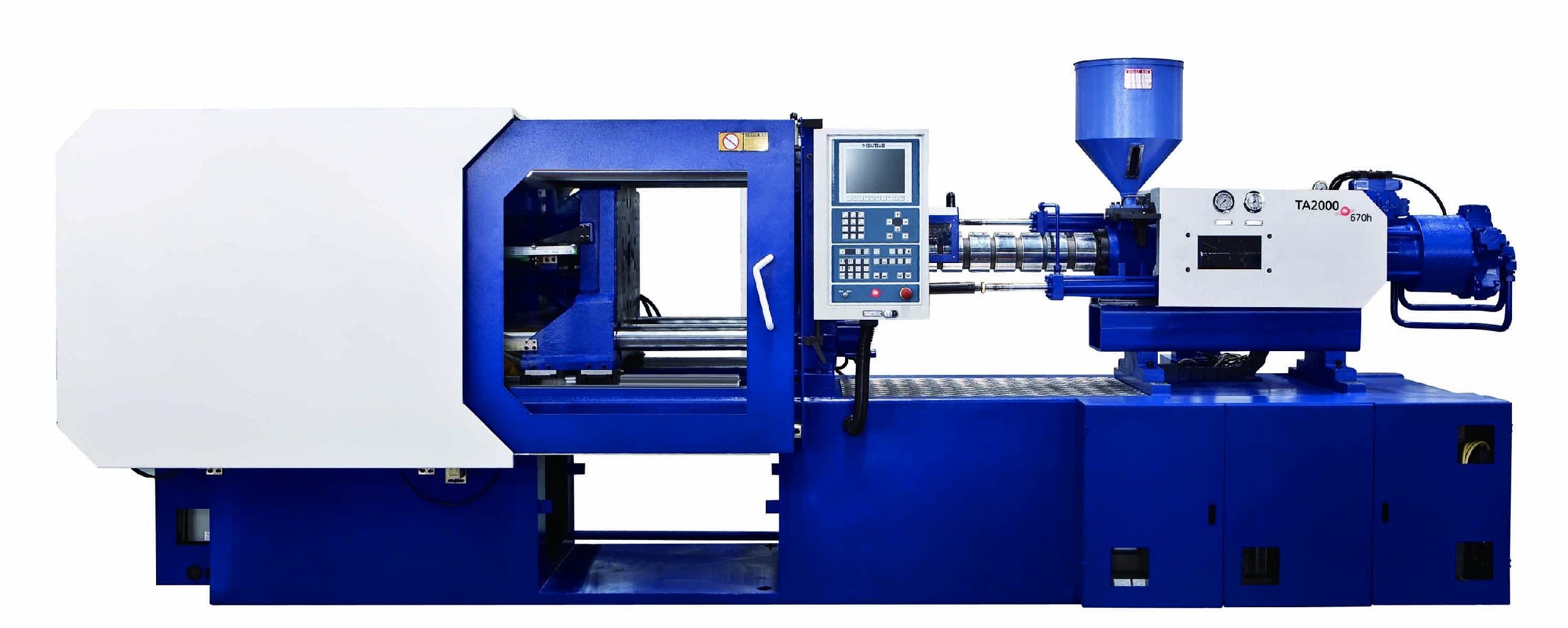

Click the buttonSmall Plastic Injection Molding Machine For Cream Bottles / Hand Care Bottles

This automatic pet bottle plastic injection stretch blow molding machine is widly used for producing all kinds of bottle including Cream bottles. Hand care bottles. lotion bottles. ect,it has wide range applications in food and beverage and Pharmacy. The device uses the servo system to control the mould , improve the rotary precision and reduce the drying cycle time.

Products

-

Bag Filling Machine

-

Beverage Filling Line

-

Biscuit Making Machine

-

Biscuit Production Line

-

Bottle Blowing Machine

-

Carbonated Drink Production Line

-

Cosmetic Filling Machine

-

Drink Production Line

-

Drinking Water Filling Machine

-

Drinking Water Production Line

-

Edible Oil Production Line

-

Fruit Juice Processing Line

-

Juice Filling Machine

-

Plastic Injection Molding Machine

-

Snack Food Production Line

-

UHT Milk Processing Line

-

Water Treatment Systems

-

Vertical Packaging Machine

-

Other Packaging Machine

-

Pillow Type Packaging Machine

-

Pre-made Pouch Packing Machinery

-

Measuring Equipment

-

Cup Filling Machines

-

Conveyor Equipment

-

Auxiliary Equipment

Automatic RO Water Treatment Plant , Stainless Steel Water Treatment Equipment

Litchi / Pulp Juice Filling Machine High Capacity Semi- Automatic CE Certificate

High Capacity Carbonated Drink Production Line Machine For 500ml-2500ml Bottle

3 In 1 Plastic Bottle Beverage Filling Machine , Automatic Soft Drink Filling Machine

Red Bull Energy Drink Production Line Automatic For Glass / PET Bottle

Fully Automatic Drinking Water Filling Machine 600-3000BPH For 5 Gallon PET Bottle

Bottled Mineral Drinking Water Production Machine / Filling Production Line

SUS304 PET Bottle Edible Oil Bottle Filling Machine For Non Viscous Liquid Filling

| Condition: | New | Type: | Stretch Blow Moulding Machine |

|---|---|---|---|

| Style: | Horizontal | Brand Name: | Qualipak |

| Model Number: | FG40/50/60/80/90 | Injection Rate: | 300g/s ~ 1200g/s |

| Certification: | CE ISO9001 | Name: | Pet Bottle Plastic Injection Stretch Blow Molding Machine |

| Material: | PP/PE/PS | System Pressure: | 14Mpa |

Automatic Small Plastic Injection Stretch Blow Molding Machine For Cream Bottles Hand Care Bottles

Applications

Product Description

- The device uses the servo system to control the mould , improve the rotary precision and reduce the drying cycle time.

- Special double cylinder horizontal valve plate injection system is adopted to make injection and storage more efficient .

- Digital sensor is used to detect the rotation of spindle and realize unattended and automatic operation.

- It can choose the function of air conditioner, shorten the cooling period of the product, and solve the problem of sticky core.

- Beautiful appearance, special plastic parts, meet the requirements of different products, multi-stage injection, pressure projection.

- The internal layout of the equipment has been optimized, the equipment is maintained, and the maintenance is more convenient.

Specifications

|

Name

|

Unit

|

FG40

|

FG60

|

FG80

|

FG100

|

|

Screw diameter

|

mm

|

40

|

45

|

50/55

|

60

|

|

L/D Ratio

|

22:1

|

22:1

|

22:1

|

22:1

|

|

|

Injection Capacity

|

9

|

176

|

260

|

314

|

415

|

|

Heating power

|

KW

|

7.5

|

10

|

10.8

|

12

|

|

Heating section

|

3+N

|

3+N

|

4+N

|

4+N

|

|

|

Injection mould clamping force

|

KN

|

400

|

600

|

800

|

1000

|

|

The injection mold opening stroke

|

mm

|

140

|

140

|

140

|

150

|

|

Mould clamping force

|

KN

|

60

|

100

|

120

|

150

|

|

Blow mold opening stroke

|

mm

|

140

|

140

|

140

|

150

|

|

Injection stroke

|

mm

|

160

|

160

|

160

|

160

|

|

Mold Size

|

mm

|

480*340

|

600*390

|

800*400

|

1000*460

|

|

Min. Thickness of Mold

|

mm

|

180

|

240

|

280

|

280

|

|

Main motor power

|

KW

|

11

|

18.5

|

22

|

30

|

|

Reject Stroke

|

mm

|

210

|

230

|

230

|

230

|

|

Dry Cycle Time

|

s

|

3.5

|

4

|

4

|

4

|

|

Total power

|

KW

|

20

|

30

|

40

|

45

|

|

Operating power

|

%

|

52-70

|

52-70

|

52-70

|

52-70

|

|

System pressure

|

Map

|

14

|

14

|

14

|

14

|

|

Compressed air pressure

|

MPa

|

0.7-1.2

|

0.7-1.2

|

0.7-1.2

|

0.7-1.2

|

|

Cooling water pressure

|

MPa

|

0.3-0.4

|

0.3-0.4

|

0.3-0.4

|

0.3-0.4

|

|

Product maximum diameter

|

mm

|

120

|

120

|

120

|

120

|

|

Product maximum length

|

mm

|

200

|

220

|

220

|

220

|

|

Product volume

|

ml

|

3-800

|

3-800

|

3-1000

|

3-1000

|

|

Dimensions

|

M

|

3*1.3*1.7

|

3.5*1.4*1.8

|

4*1.6*2

|

4.5*1.8*2

|

|

Equipment weight

|

Ton

|

3.5

|

5

|

8

|

10

|

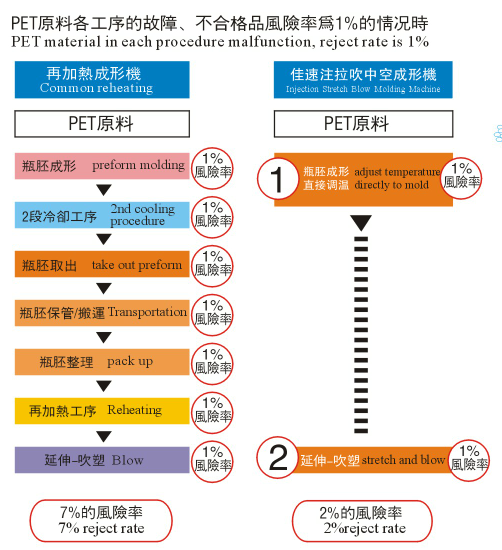

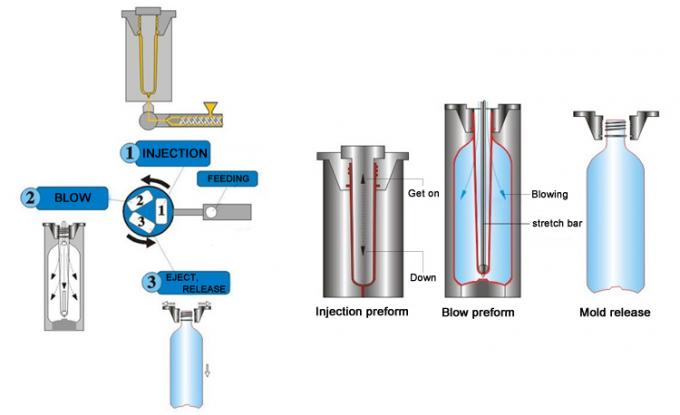

Flow Chart

Product show

Output Products

Our services

- We offer two year warranty. We will replace the accessories for free within first two years.

- We can design the machine according to your requirement, and we will provide you with professional advice.

- When the equipment is shipped to your factory, our engineers will go to your factory for installation, testing and training.

- We will provide the loading list in time to ensure that you can get the machine quickly.

- Welcome to visit our factory at any time. In the factory, you can see the operation of the machine . When you come, we will arrange a car to pick you up.

- If we get permission from customers who bring machines from us, we can tell you their contact information and you can visit their factory.

-

PET Bottle Blow Molding Machine / Fully Automatic Injection Moulding Machine

PET Bottle Blow Molding Machine / Fully Automatic Injection Moulding Machine

Adopt fully enclosed safety doors to ensure sanitary and the...

→ -

Less Energy Pet Bottle Blowing Machine , 80 Ton PET Preform Molding Machine

Less Energy Pet Bottle Blowing Machine , 80 Ton PET Preform Molding Machine

The equipment is adopted The special PET screw can significa...

→ -

160T – 1000T Plastic Injection Molding Machine Automatic / Semi Automatic

160T – 1000T Plastic Injection Molding Machine Automatic / Semi Automatic

Plastic injection molding Machine for plastic PET Bottle Pre...

→ -

2000BPH – 10000BPH PET Preform Injection Molding Machine For Bottle Preform / Bottle Cap

2000BPH – 10000BPH PET Preform Injection Molding Machine For Bottle Preform / Bottle Cap

The PET preformed injection molding machine from our company...

→